Carbon fiber winding drum supporting ring

A carbon fiber and support ring technology, applied in the field of textile machinery accessories, can solve the problems of high cost, complex installation and positioning structure, etc., and achieve the effect of simple structure and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

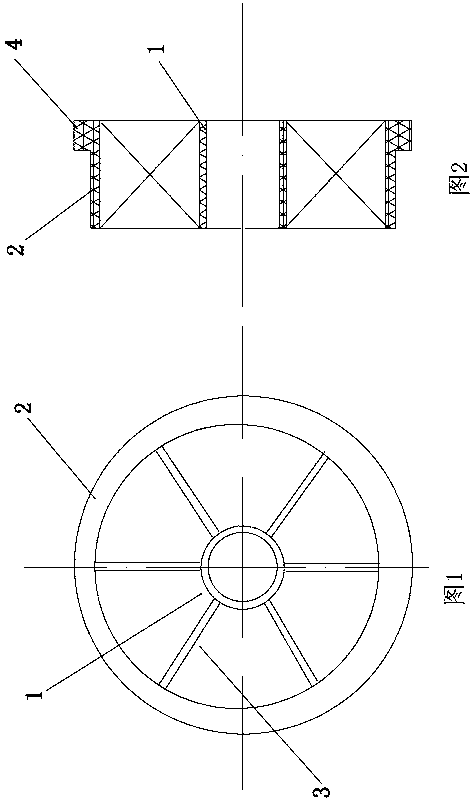

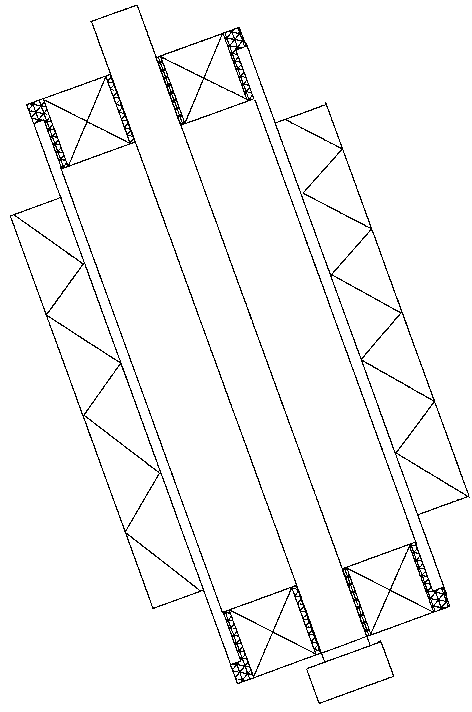

[0016] As shown in Figure 1 and 2.

[0017] A carbon fiber reel support ring, which is composed of an inner ring 1, an outer ring 2 and a connecting rib 3, as shown in Figure 1, the inner ring 1 and the outer ring 2 are connected into a whole by six connecting ribs 3 (connecting The number of ribs can also be three or more than six), the aperture of the inner ring 1 matches the support rod on the pay-off bracket, and there should be a clearance fit between the two so that the support ring of the present invention can be flexible on the support rod rotation, while the inner ring also acts as a bearing. The outer diameter of the outer ring 2 matches the inner diameter of the carbon fiber reel core, and the two should be tightly fitted to prevent the carbon fiber reel from slipping on the support ring of the present invention. One end of the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com