Unsaturated polyester resin-tail gas purification control system

A resin and tail gas treatment technology, applied in the field of tail gas treatment, can solve the problems of substandard tail gas discharge, low adsorption efficiency, high operating cost, etc., and achieve the effects of low operating cost, high recycling rate, and high degree of self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

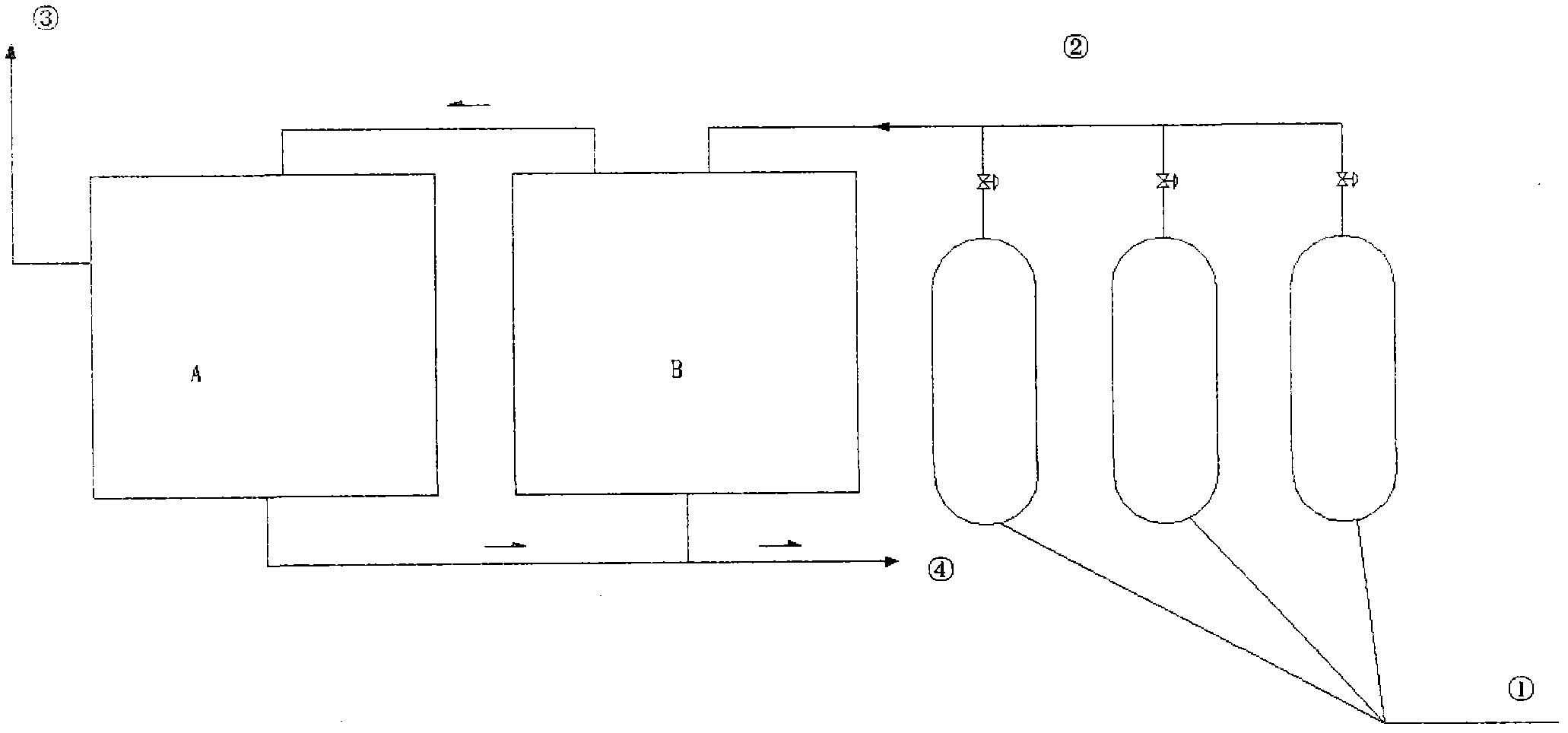

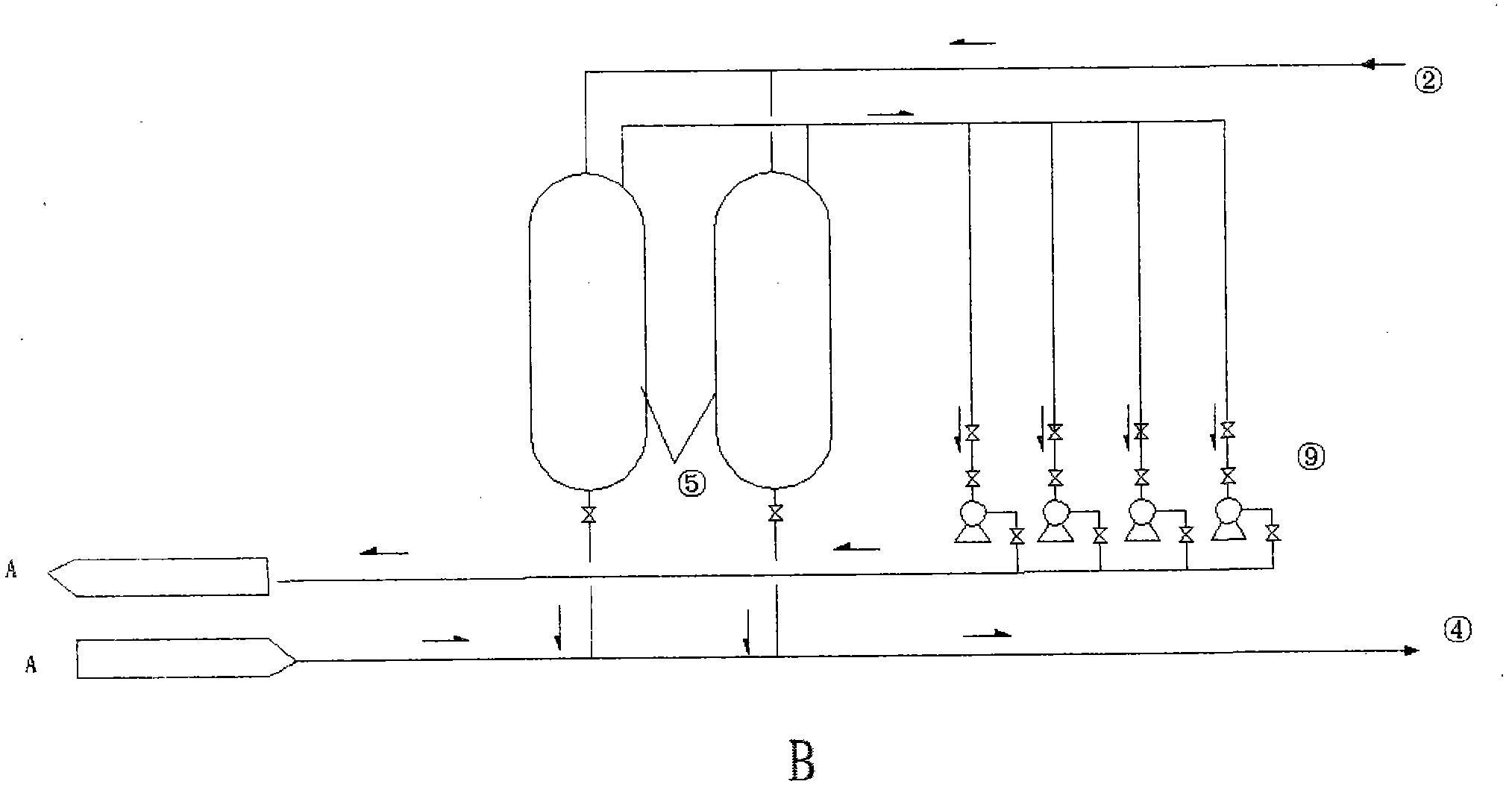

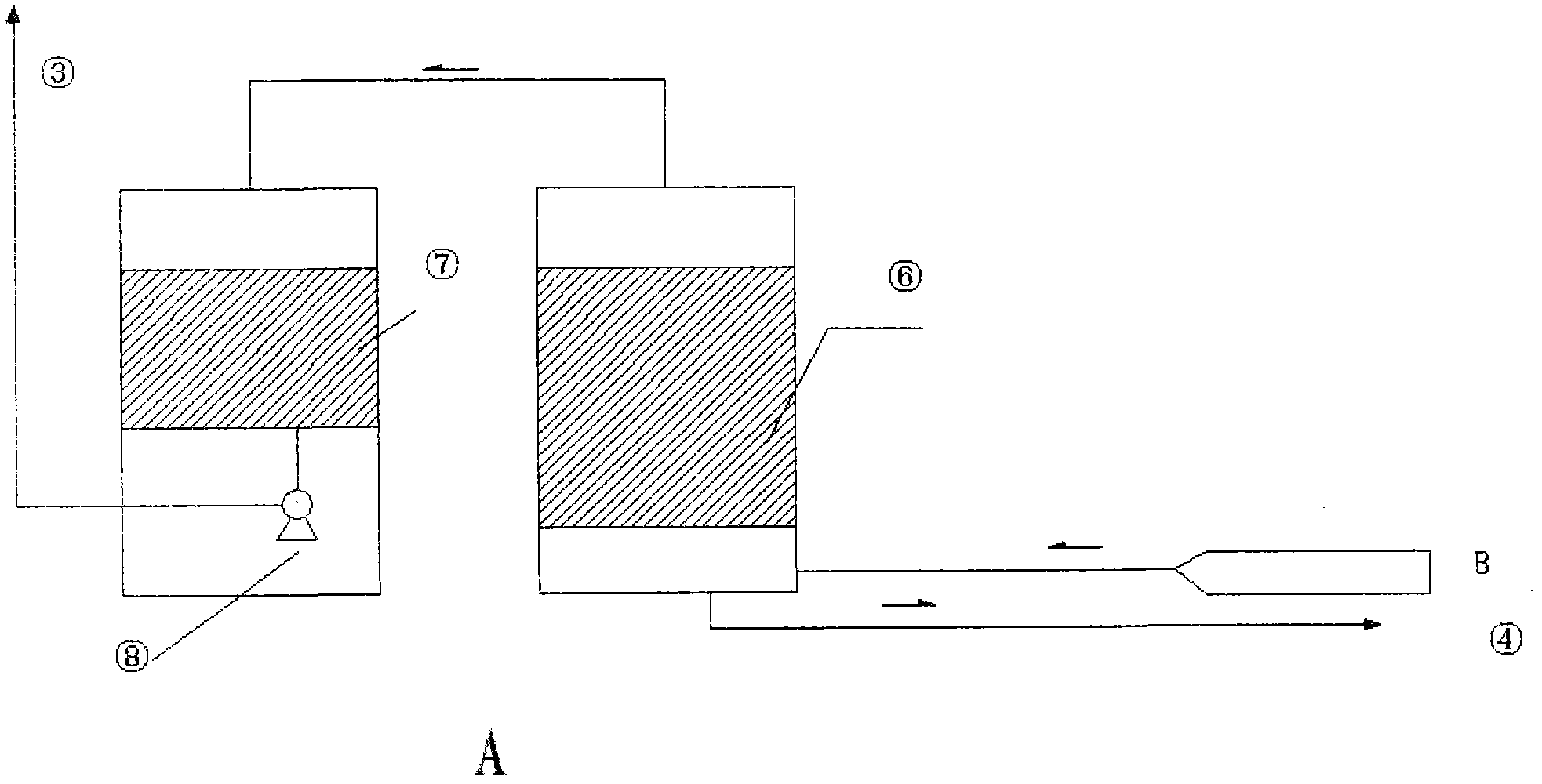

[0013] See Figure 1 ~ Figure 3 , The description of the serial number is as follows: ① is the reactor; ② is the tail gas; ③ is the venting; ④ is the recovery; ⑤ is the vacuum tank; ⑥ is the Bohr ring packing; ⑦ is the activated carbon; ⑧ is the induced draft fan; ⑨ is the vacuum pump unit ; The present invention includes an automatic control device, which is controlled by the DCS from the exhaust gas generation, collection, and purification control.

[0014] The device is to collect the tail gas from the reaction kettle and the tail gas from the cross-linking dilution kettle to the tail gas main pipe, and then figure 2 The vacuum system shown in is sent to the purification unit, in image 3 After being purified by a water vapor separator and a filter, it will be discharged into the atmosphere after the test reaches the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com