self-boosting brake

A self-energizing and brake technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problem of smooth brake release and achieve the effect of rapid braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

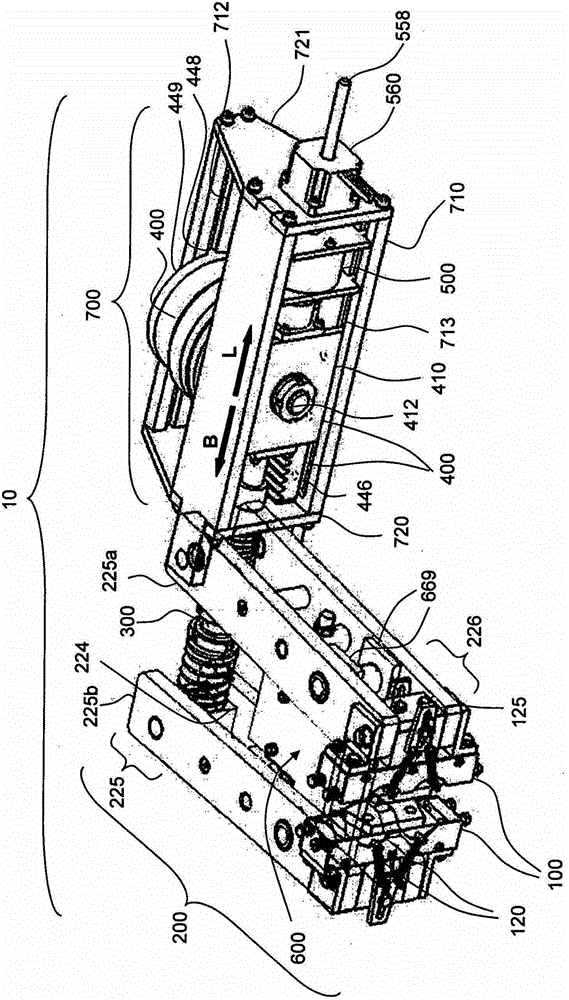

[0083] Figure 3b A schematic diagram showing a passive brake in the form of a lever brake. The brake is shown without a brake member 119 or brake disc 119 .

[0084] This brake also has two mutually symmetrical brake heads 100 opposite to each other (see figure 1 ), the brake head can bear against the brake disc 119 passing between the brake heads 100 on both sides with the working surface of the friction pad 116 using the lever set 200 . To this end, the brake lever 220 is rotated about a fixed lever center of rotation 221 , which in this embodiment is located at a fixed end 227 a or 227 b of the brake lever 220 , respectively. The brake head 100 passes through a structure (which is combined with the pin 222) figure 2 (similar to those described) are each rotatably centered on the brake lever 220 , so that here, too, the running surfaces of the friction pads 116 are always in contact with each other in the braking position, regardless of the inclination of the brake leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com