Inward recess preventing capillary tube capable of being fast installed

A capillary tube and internal thread technology, which is applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problem of inward depression of the capillary port part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

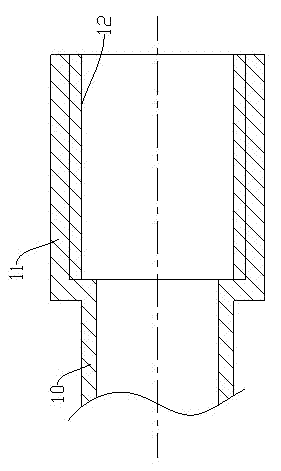

[0011] Examples, see figure 1 As shown: the anti-sag quick-fit capillary includes a body 10 , and the port of the body 10 is provided with an internal thread 12 . In this way, when the capillary is connected to other components, the connection speed is faster due to the screw connection. At the same time, after the connection, the pressure on the port part is outward from the inside of the capillary, so that the port part of the capillary will not sink inward.

[0012] Optimally, the port portion of the body 10 is provided with an external flare 11 , and the internal thread 12 is located on the inner surface of the external flare 11 . The so-called outer flare 11 means that the inner diameter of this place is larger than the inner diameter of the body 10 . In this way, it is not only beneficial to the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com