Vacuum pulse hydrogen annealing apparatus and method for electric pure iron

A technology of vacuum pulse and hydrogen annealing, which is applied in the field of metal heat treatment, can solve the problems of inability to meet the needs of DT4 electrical pure iron processing, safety, explosion and other problems in annealing equipment, so as to reduce human factors, prevent atmosphere leakage, and achieve surface smoothness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

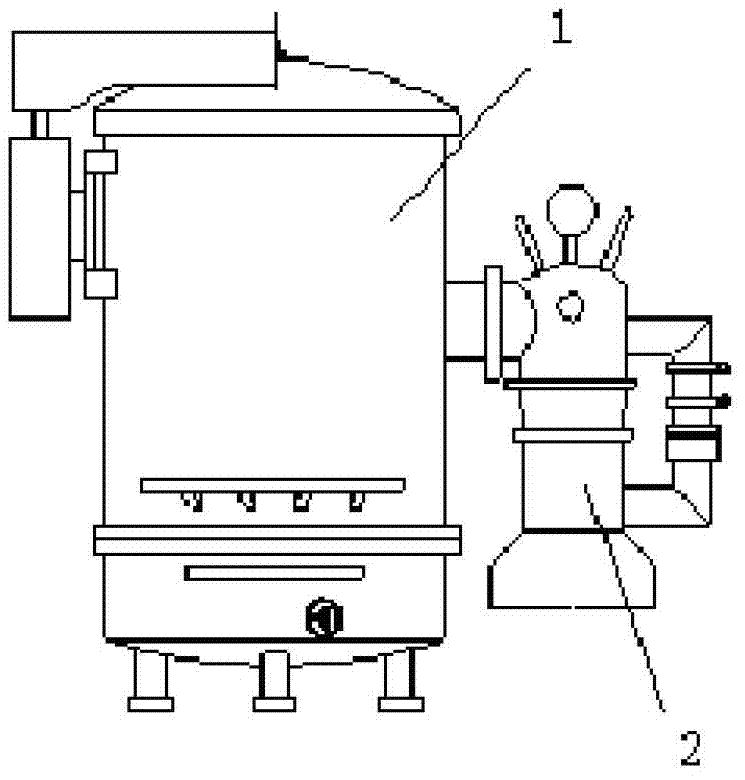

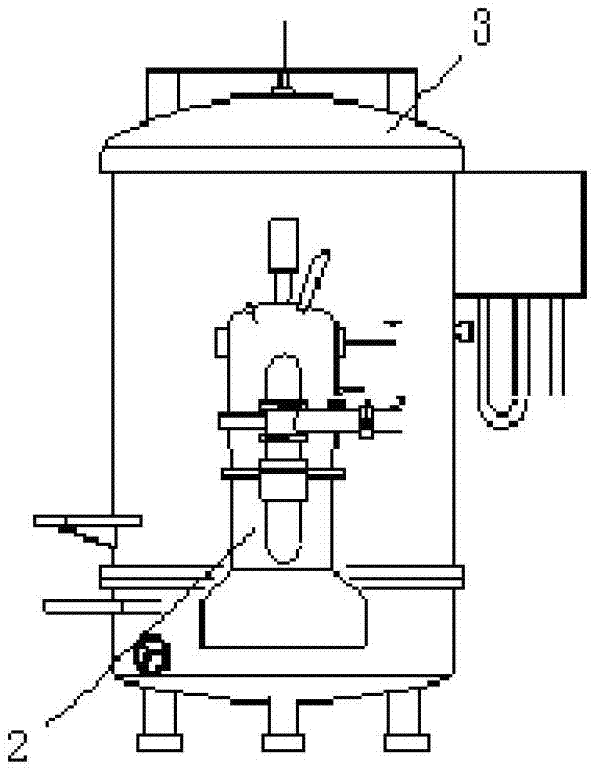

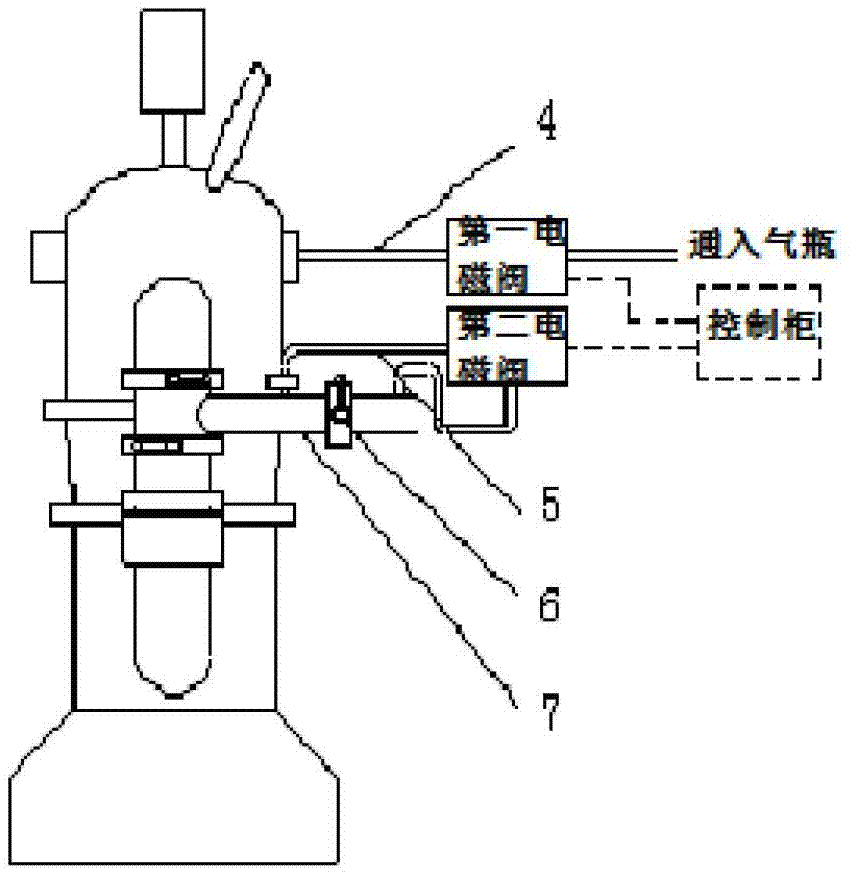

[0048] Through the technical transformation of the original vacuum annealing furnace, an automatic pulse atmosphere control device was added, so that the original electrical pure iron vacuum hydrogen annealing manual control was changed to automatic control, which reduced the labor intensity of the operator and improved the heat treatment process. control precision. On this basis, the process test of DT4 electrical pure ferromagnetic material was carried out, and the obtained results showed that this technology can improve the magnetic performance and meet the higher magnetic performance index of DT4. Vacuum pulse hydrogen annealing also helps to improve the surface quality of DT4 electrical pure iron workpieces, making the workpiece surface smooth. The usual hydrogen annealing refers to the introduction of hydrogen gas under normal pressure. This technology allows DT4 electrical pure iron to pass hydrogen gas in a pulsed state under the vacuum state, and uses the reducibility...

Embodiment 2

[0059] A vacuum pulse hydrogen annealing method for electrical pure iron, comprising the following steps:

[0060] Step 1. Clean the workpiece with gasoline to make the surface of the workpiece free of dirt and oil stains;

[0061] Step 2, put the workpiece into the effective heating zone of the furnace body 1;

[0062] Step 3. Insert the thermocouple 3-1 from the furnace cover 3 into the effective heating zone in the furnace, and tighten the nut 3-2 to fix the thermocouple;

[0063] Step 4. Vacuumize the furnace body to make the vacuum degree reach 20Pa, and then heat the workpiece to raise the temperature of the workpiece to 800°C. Starting from 800°C, the temperature of the workpiece is raised to 880°C at a heating rate of 50°C / h. During the heating process, continuously evacuate the furnace body to keep the vacuum at 20Pa;

[0064] Step 5. Introduce hydrogen into the furnace, and keep the introduced hydrogen in the furnace for 600s, then extract the reacted waste gas out...

Embodiment 3

[0068] A vacuum pulse hydrogen annealing method for electrical pure iron, comprising the following steps:

[0069] Step 1. Clean the workpiece with gasoline to make the surface of the workpiece free of dirt and oil stains;

[0070] Step 2, put the workpiece into the effective heating zone of the furnace body 1;

[0071] Step 3. Insert the thermocouple 3-1 from the furnace cover 3 into the effective heating zone in the furnace, and tighten the nut 3-2 to fix the thermocouple;

[0072] Step 4. Vacuumize the furnace body to make the vacuum degree reach 20Pa, and then heat the workpiece to raise the temperature of the workpiece to 800°C. Starting from 800°C, the temperature of the workpiece is raised to 900°C at a heating rate of 50°C / h. During the heating process, continuously evacuate the furnace body to keep the vacuum at 20Pa;

[0073] Step 5. Introduce hydrogen into the furnace, and keep the hydrogen gas in the furnace for 650s, then extract the waste gas after reaction out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com