Tissue engineering controllable hydraulic bioreactor

A technology of bioreactor and tissue engineering, which is applied in the direction of special-purpose bioreactor/fermenter, tissue cell/virus culture device, biochemical instrument, etc., which can solve the problem of single direction of force application and lack of corresponding support on the non-stressed surface of cartilage. Mechanical stimulation, uneven mechanical properties of cartilage, etc., to reduce the possibility and simplify the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

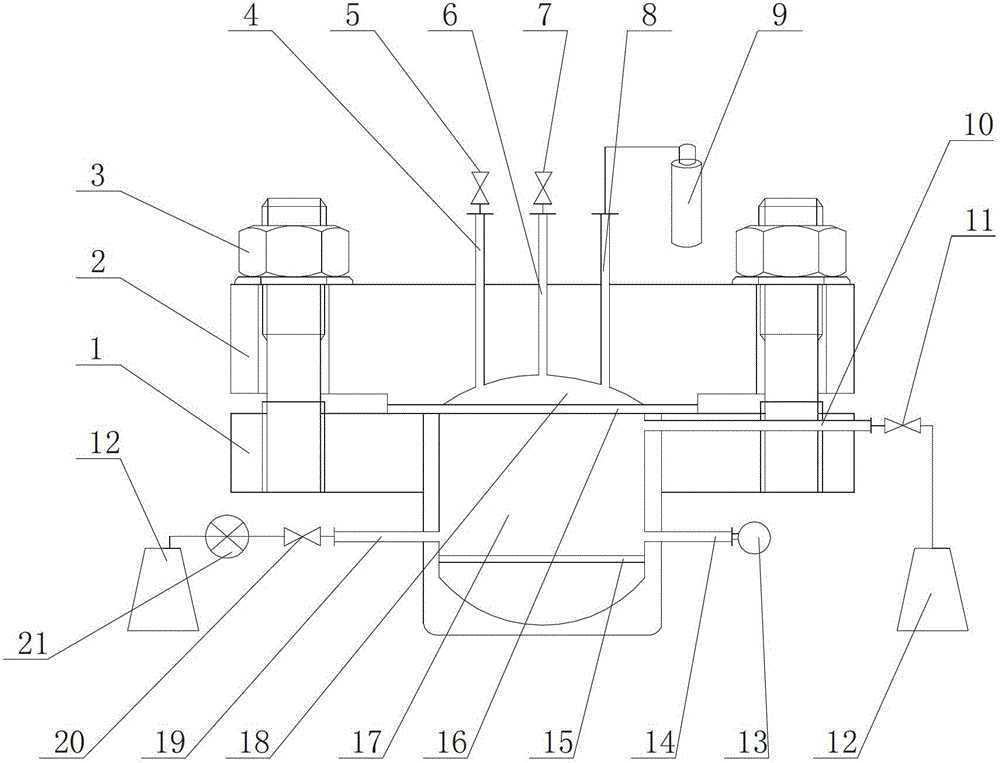

[0024] like figure 1 As shown, a controllable hydraulic bioreactor for tissue engineering includes a tank body 1, a top cover 2 is arranged on the tank body 1, and a controllable hydraulic system is arranged on the upper end of the top cover 2, and the tank body 1 is provided with a controllable hydraulic system. The lower part of the body 1 is provided with a circulation perfusion system. Cultures housed in tanks are provided with the required hydraulic stimulation by a controllable hydraulic system during pressurized stimulation. During cultivation, a recirculating perfusion system supplies the culture with fresh medium and exchanges out old medium.

[0025] A flexible diaphragm 16 is arranged inside the tank body 1 , and the flexible diaphragm 16 separates the chamber formed by the tank body 1 and the top cover 2 into a culture chamber 17 and a pressurized chamber 18 . The flexible diaphragm 16 can also be replaced by other separators with the same function, so any replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com