Automatic implementation method for high-uniformity magnet shim coil design

A shimming coil and uniformity technology, applied in the direction of measuring magnetic variables, measuring devices, instruments, etc., can solve problems such as difficult winding, irregular coil shape, and unrealizable design schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

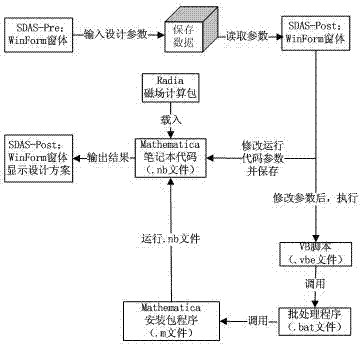

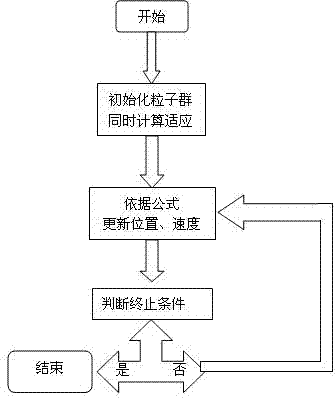

[0019] An automatic implementation method for the design of high-uniformity magnet shim coils, comprising the following steps:

[0020] (1) Use the nuclear magnetic resonance probe to measure the magnetic field intensity distribution within the field area, and use the least square method to fit the first 10 order components of the magnetic field according to the spherical harmonic function, and obtain the intensity values of each order shimming quantity;

[0021] (2) In the data interface, input the strength value of the above shimming amount and the operating current density value required for shimming, the length of the shimming area, the diameter of the shimming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com