A kind of pollution test method of DC surge arrester

A pollution test and arrester technology, which is applied in the field of pollution experiments, can solve the problems of weakening the external insulation assessment ability of the arrester, the insulator does not have internal components, and the thermal stability of the arrester cannot be assessed, and the test method is simple, reliable, easy to implement, and the test method practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

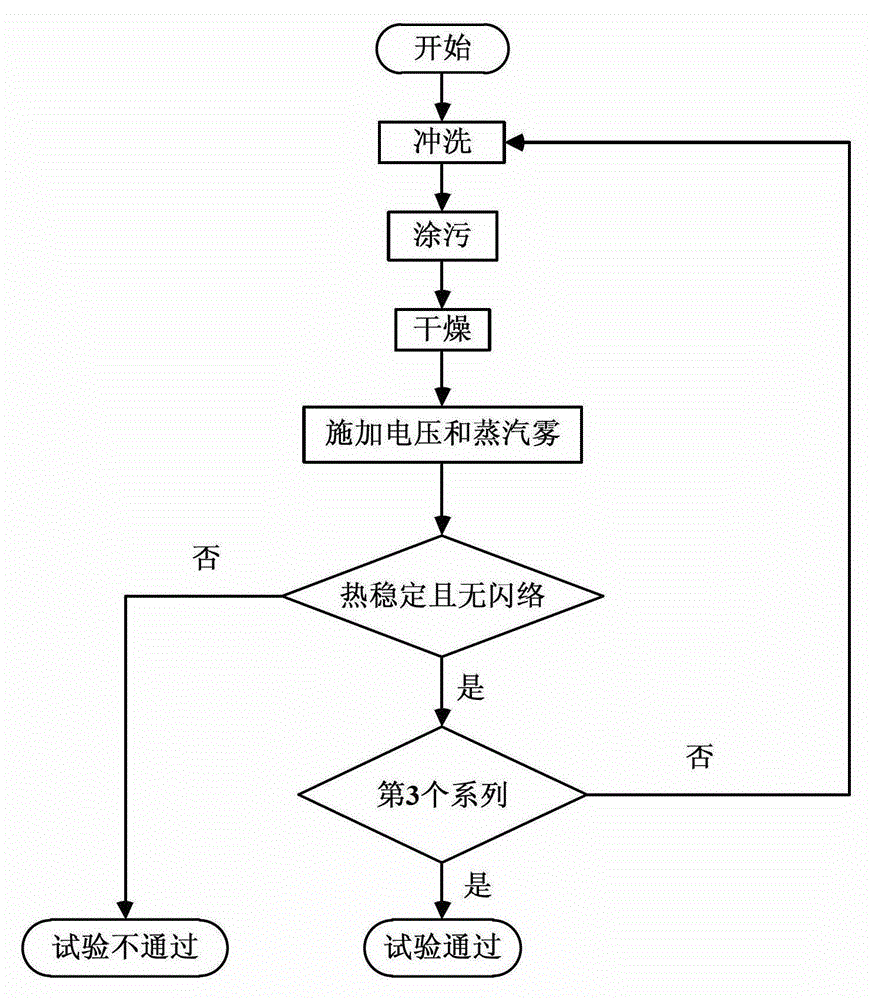

[0029] Such as figure 1 , a DC arrester pollution test method, the method comprises the following steps:

[0030] Step 1: Rinse the DC arrester, and paint the dirty liquid on the DC arrester;

[0031] Step 2: After the dirt layer is dried, apply the continuous operating voltage of the DC arrester and start the fog generator;

[0032] Step 3: Continue to apply the continuous operating voltage of the DC arrester until the danger of external flashover and internal thermal collapse is eliminated;

[0033] Step 4: According to steps 1, 2 and 3, cycle the DC arrester;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com