Multi-parameter sensor for pH, conductivity and temperature

A conductivity and multi-parameter technology is applied to thermometers, thermometers and instruments with direct heat-sensitive electric/magnetic elements, which can solve the problems of unfavorable continuous measurement, short service life, single sensor function, etc., and achieve convenience. Lead-out processing, easy on-site installation, and improved analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

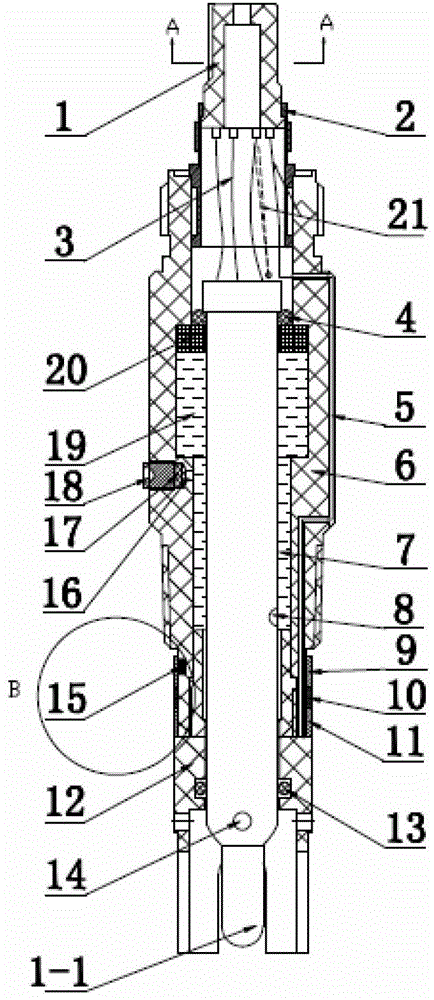

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

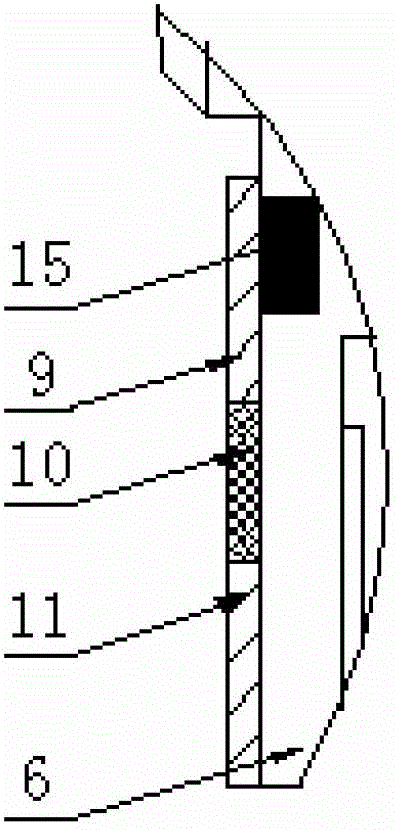

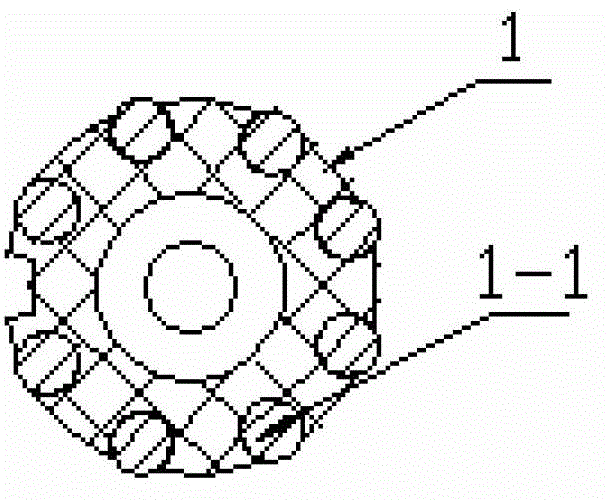

[0030] Such as Figure 1 to Figure 3 As shown, a pH value, conductivity and temperature multi-parameter sensor, including a sensor housing 6 and a glass electrode housing 7, is characterized in that the glass electrode housing 7 is set in the sensor housing 6, and The sensor housing 6 is also provided with a conductivity measurement component and a temperature measurement element 15 for measuring conductivity parameters.

[0031] The conductance measurement assembly includes a first conductance electrode 9, an insulator 10 and a second conductance electrode 11 which are successively set on the sensor housing 6, and the temperature measuring element 15 is a platinum resistance embedded in the sensor housing 6. .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com