Multi-batch metering oil injection system and method

A batch and oil injection technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of affecting the production site environment, increasing the labor intensity of employees, and inaccurate liquid measurement, so as to achieve the benefit of product quality Control, save labor costs and resources, and avoid large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

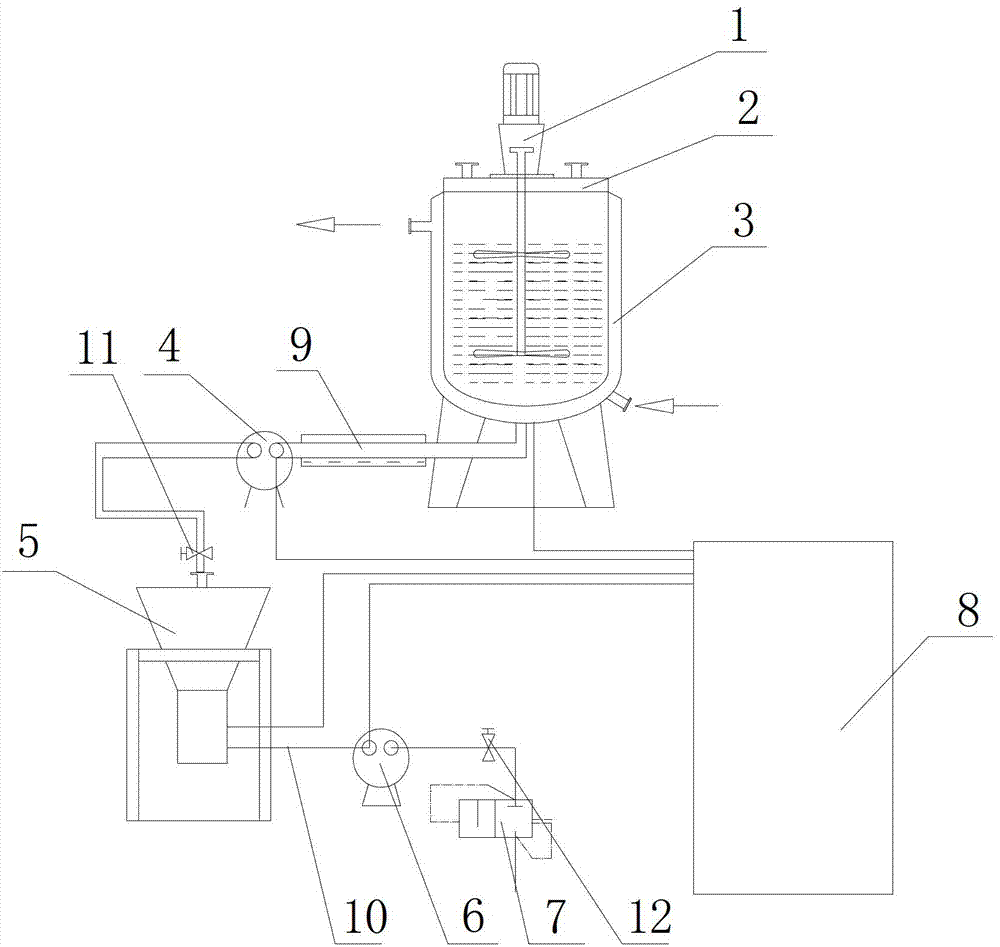

[0037] A kind of oil injection system of multi-batch metering in this embodiment, such as figure 1 As shown, it includes oil storage tank 2, batch measurement scale 5 and electrical control cabinet 8, the outlet end of oil storage tank 2 is connected with the inlet end of batch measurement scale 5 through the first pipeline 9, and the outlet end of batch measurement scale 5 passes through The second pipeline 10 is externally connected to the internal mixer; the first pipeline is provided with the first oil pump 4, the second pipeline is provided with the second oil pump 6, and the oil storage tank, the first oil pump, the second oil pump and the batch measuring scale are respectively connected with the electrical The electrical connection of the control cabinet; the oil storage tank includes an inner tank and a preheating sleeve, the inner tank is set in the preheating sleeve, and the heat medium 3 is filled between the inner tank and the preheating sleeve; the batch measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com