Rotary drilling rig and bittern collecting method

A technology of a rotary drilling rig and a collection method, which is applied to drilling equipment and methods, rotary drilling rigs, earthwork drilling and mining, etc., and can solve problems such as inability to collect brine, low drilling efficiency, cumbersome operations, etc. Improved hole efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The basic idea of the present invention is to change the drill rod and drilling tool of the existing rotary drilling rig so that it can perform positive circulation rotary drilling, thus on the one hand eliminating the frequent soil extraction and unloading process of the existing rotary drilling rig, Simplify the operation; on the other hand, it can also realize the drilling of deep holes.

[0032] Below in conjunction with accompanying drawing, each preferred embodiment of the present invention is described further:

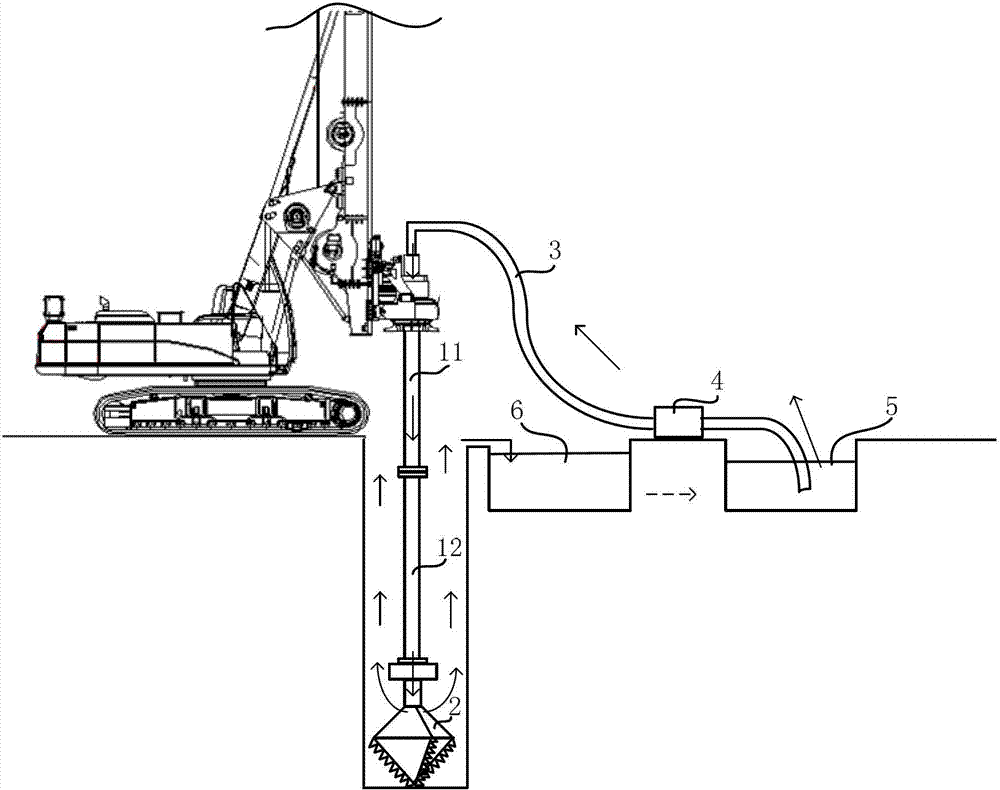

[0033] figure 1 The structure of the rotary drilling rig provided by Embodiment 1 of the present invention is shown, and the drilling rig includes:

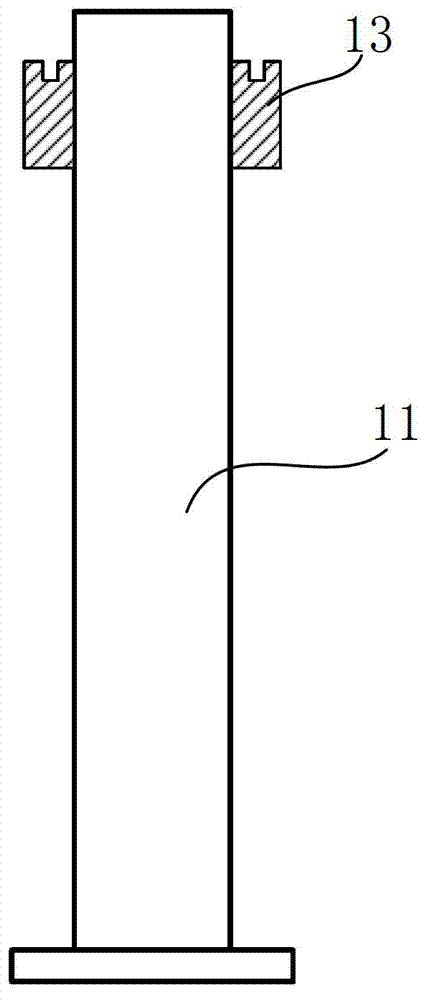

[0034] The torsion transmission drill pipe is provided with a grouting channel inside the drill pipe, and the grouting passage is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com