Construction method for post-injection cement mortar masonry brickwork

A construction method and masonry technology, which are applied in the processing of building materials, construction, building components, etc., can solve the problems of small resistance to horizontal load and continuous operation in the height direction, and achieve increased horizontal friction resistance and market application prospects. The effect of large and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings, taking a masonry component with a size of 200mm×250mm×600mm as an example.

[0042] see Figure 1-13 , the present invention comprises the following steps:

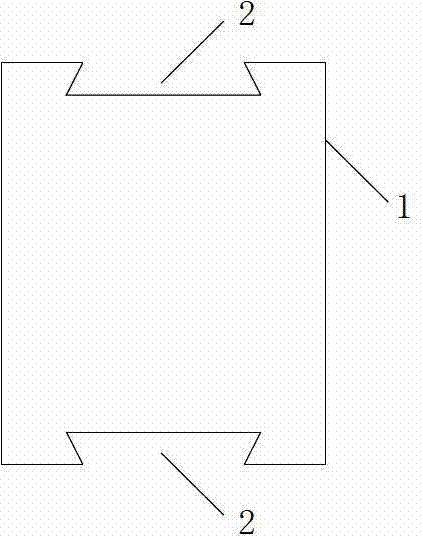

[0043] 1) Improve the geometric shape of masonry components (mainly to set inner grooves on the surface of the components, there are mainly three types of components);

[0044] Commissioning, Procurement and Production Figure 1-7 Three kinds of masonry components are shown: special masonry standard part 1, masonry part 4 with one side groove and bottom ungrooved masonry part 5.

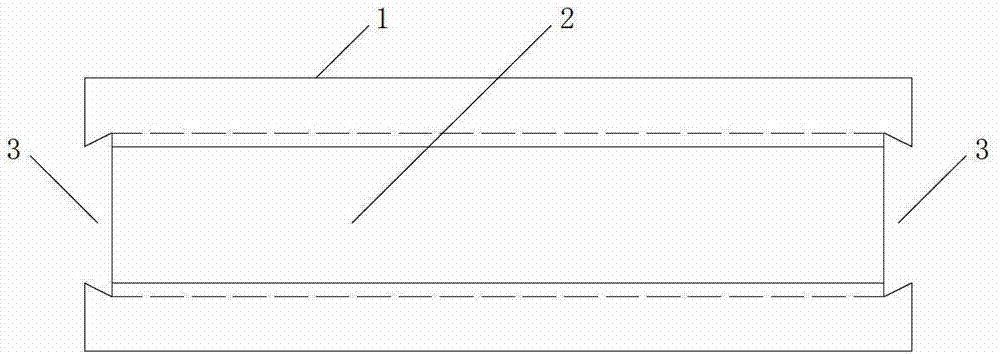

[0045] The two faces of the special masonry standard part 1 of 200mm x 600mm are provided with plane slots 2 for the special masonry standard part, and the two faces of 200 mm x 250 mm are provided with the side slots 3 of the special masonry standard part.

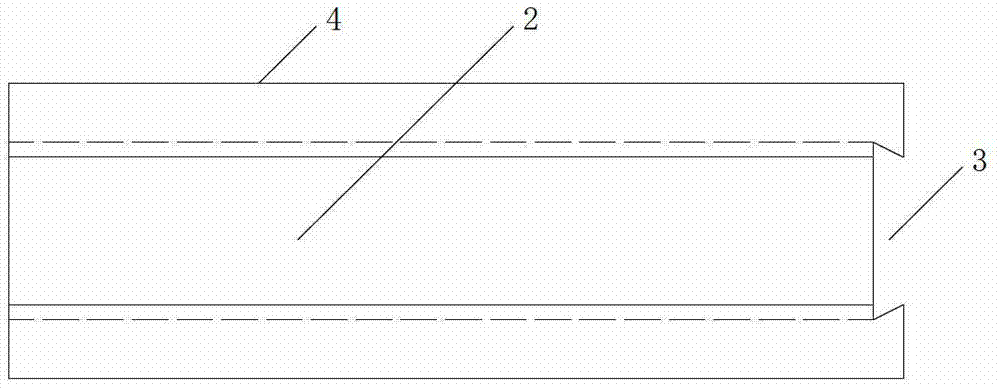

[0046] One side of 200mm×600mm masonry part 4 with single-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com