Apparatus for cleaninging alumina crusting blocks on binode unit

An aluminum oxide and double anode technology, which is applied in the field of devices for removing aluminum oxide crusts on the double anode group, can solve the problem of not being able to adapt to the cleaning and production of double carbon block anodes, and achieve good dust collection facilities and prevent noise. and dust diffusion, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

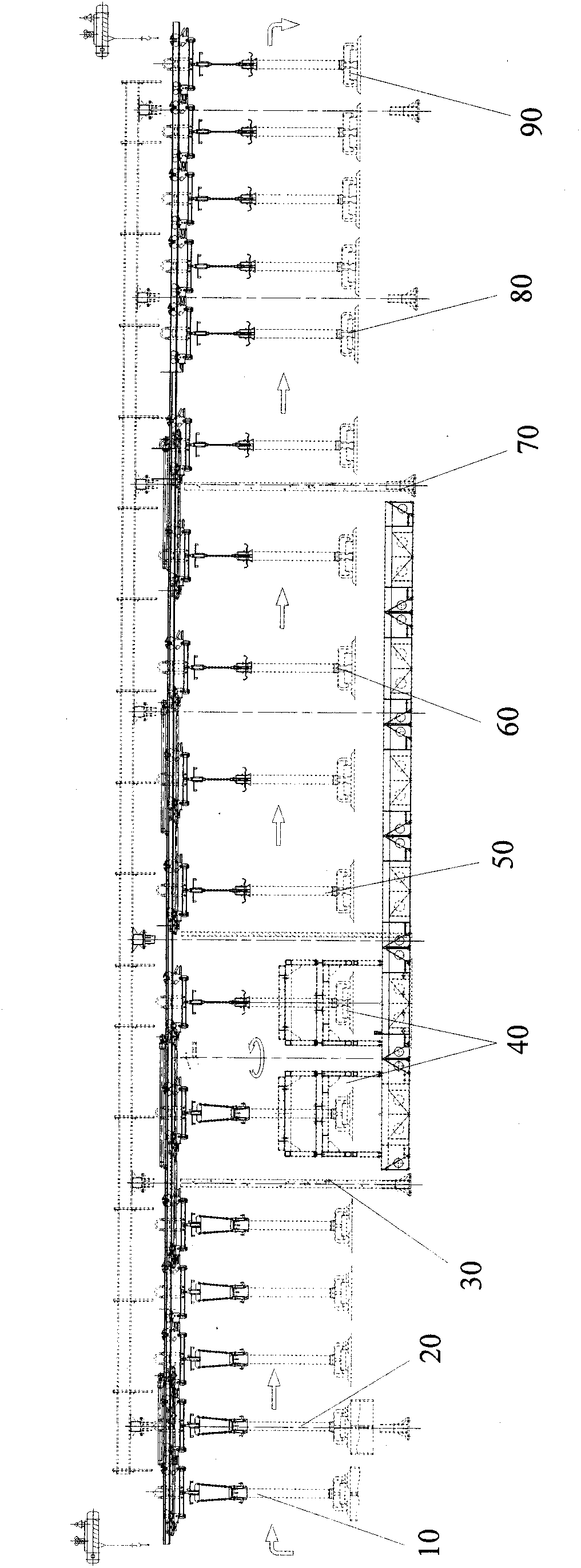

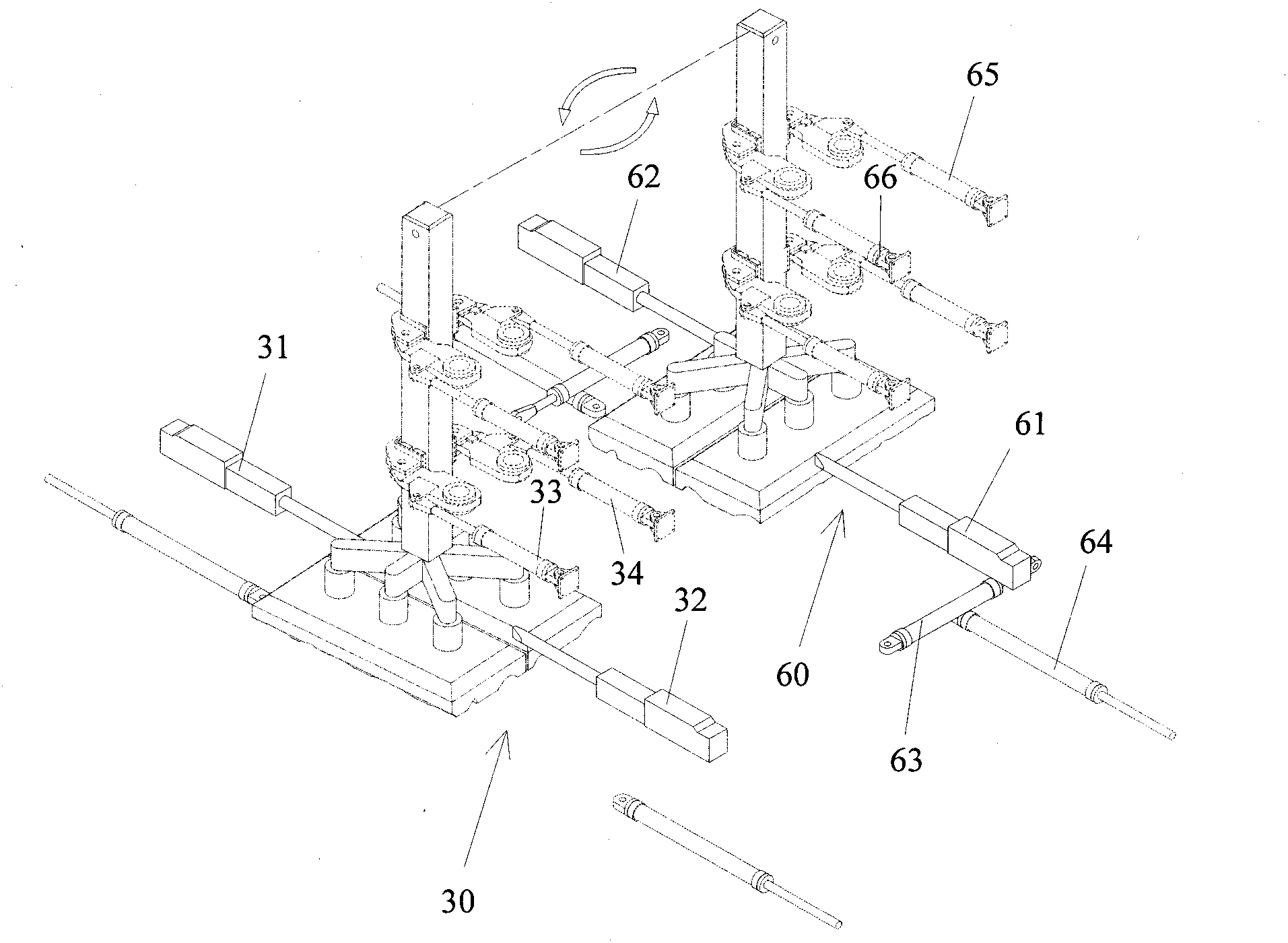

[0029] see figure 1 As shown, the present invention is used to remove the cleaning equipment of alumina crust block, and its structure mainly comprises: the vibration cleaning machine 10 of the first station, the vibration cleaning machine 20 of the second station, and the hydraulic system that is matched with it 30 and PLC control system 40.

[0030] The vibrating cleaning machine 10 at the first station includes a left side vibrator 11 and a right side vibrator 12 respectively. The left side vibrator 11 and the right side vibrator 12 are all carried by the propulsion cylinder to vibrate from the left and right sides with the vibrator. The left side vibrator 11 and the right side vibrator 12 are also designed with upper and lower two-layer clamping mechanisms respectively, which are the first clamping mechanism 13 and the second clamping mechanism 14, which mainly implement fixed clamping on the anode guide rod 50; Guarantee that the pole stump 60 does not shake during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com