Powder material transport monitoring system and method

A powder material and monitoring system technology, which is applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of the semi-automatic measurement system, which is bulky, poor in scalability, and unable to meet the needs of coal transportation monitoring, etc., to achieve Improve work inspection efficiency and save money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

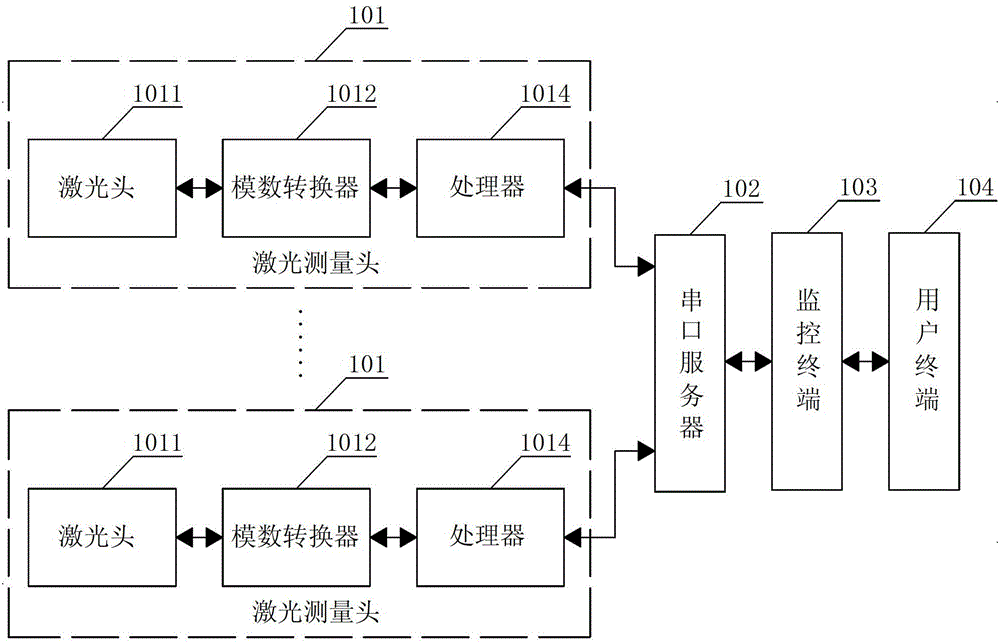

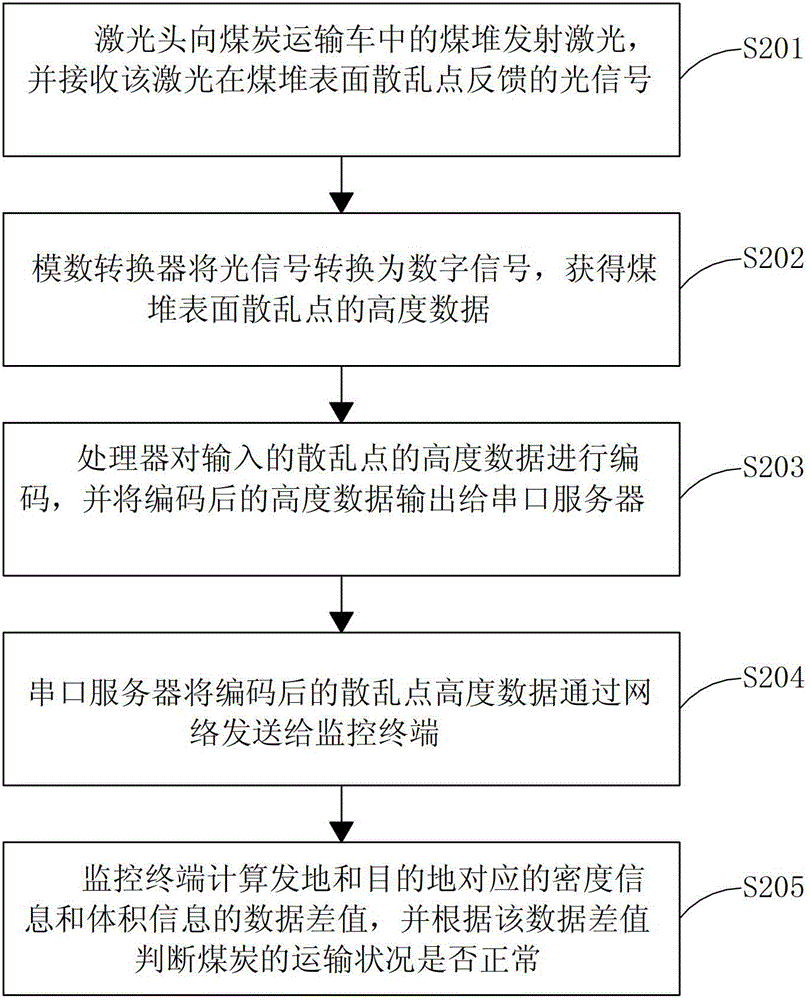

[0037] Please refer to figure 1 as shown, figure 1 The block diagram of the powder material transportation monitoring system provided by the embodiment of the present invention. Taking the powder material as coal as an example, the coal transportation monitoring system in this embodiment includes twelve laser measuring heads 101 , a serial port server 102 and a monitoring terminal 103 . The laser measuring head 101 includes a laser head 1011 , an analog-to-digital converter 1012 and a processor 1013 . Among them, the number of laser measuring heads can be adjusted according to the width of the coal transport vehicle and the measurement accuracy of the user, and is not fixed at twelve.

[0038] The laser measuring head 101 is used to collect height data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com