Adjustable precision steel forging vise

An adjustable and precise technology, applied in vices, manufacturing tools, etc., can solve the problems of affecting the size and stability of the workpiece clamped by the vice, occupying the depth resources of the throat of the vice, and the thread cannot be repaired and replaced, and achieves a compact structure. , the effect of optimizing mechanical properties and reducing welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

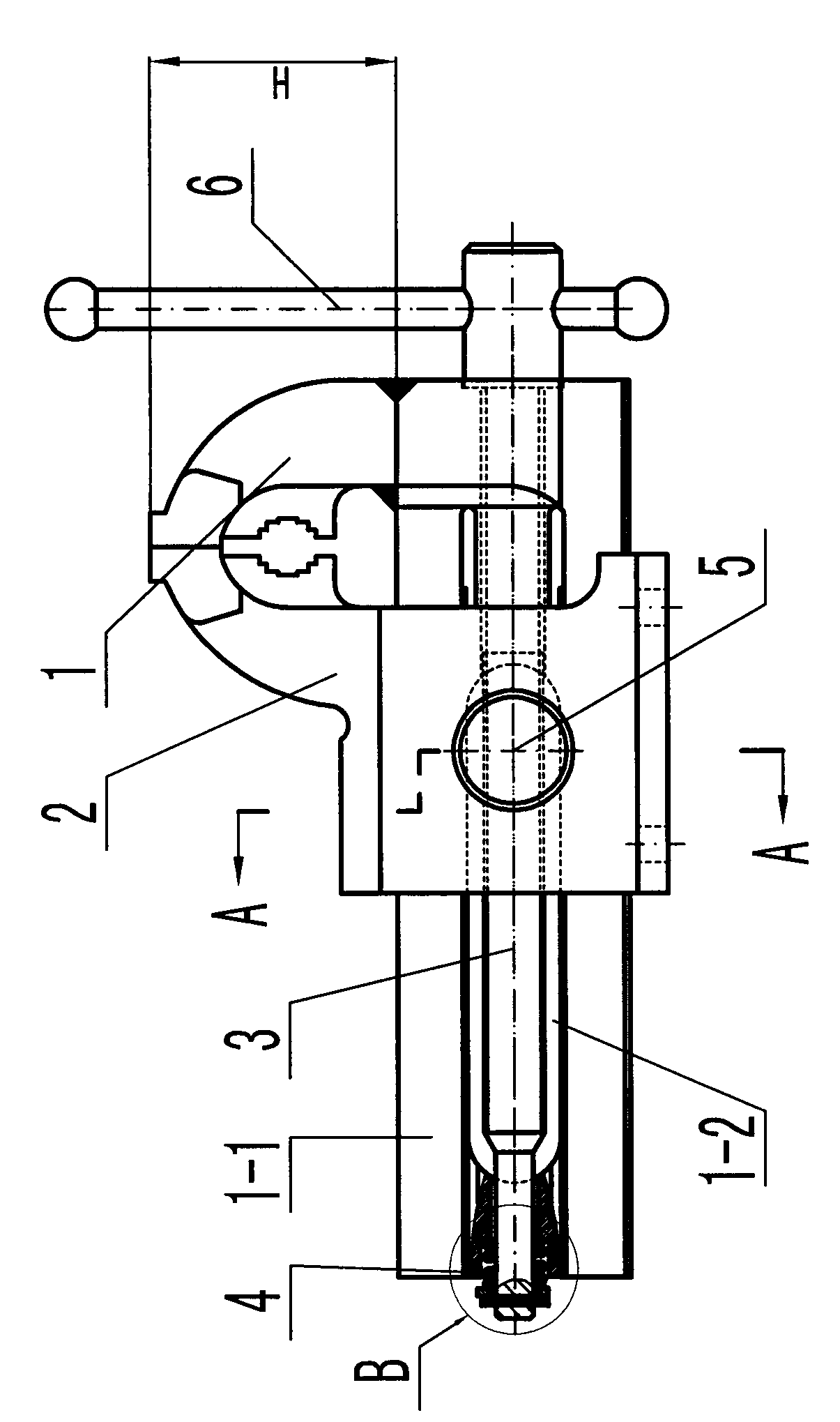

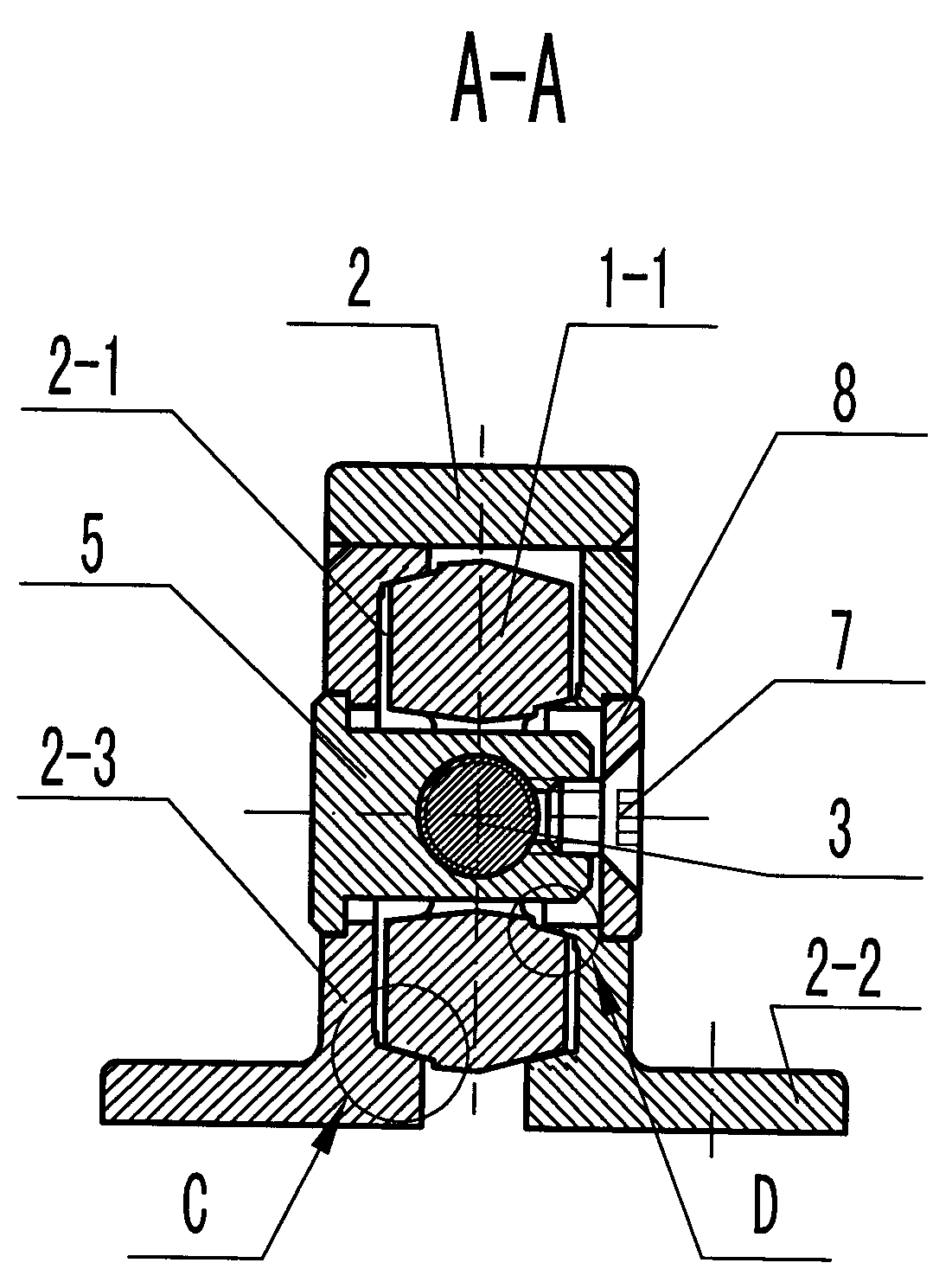

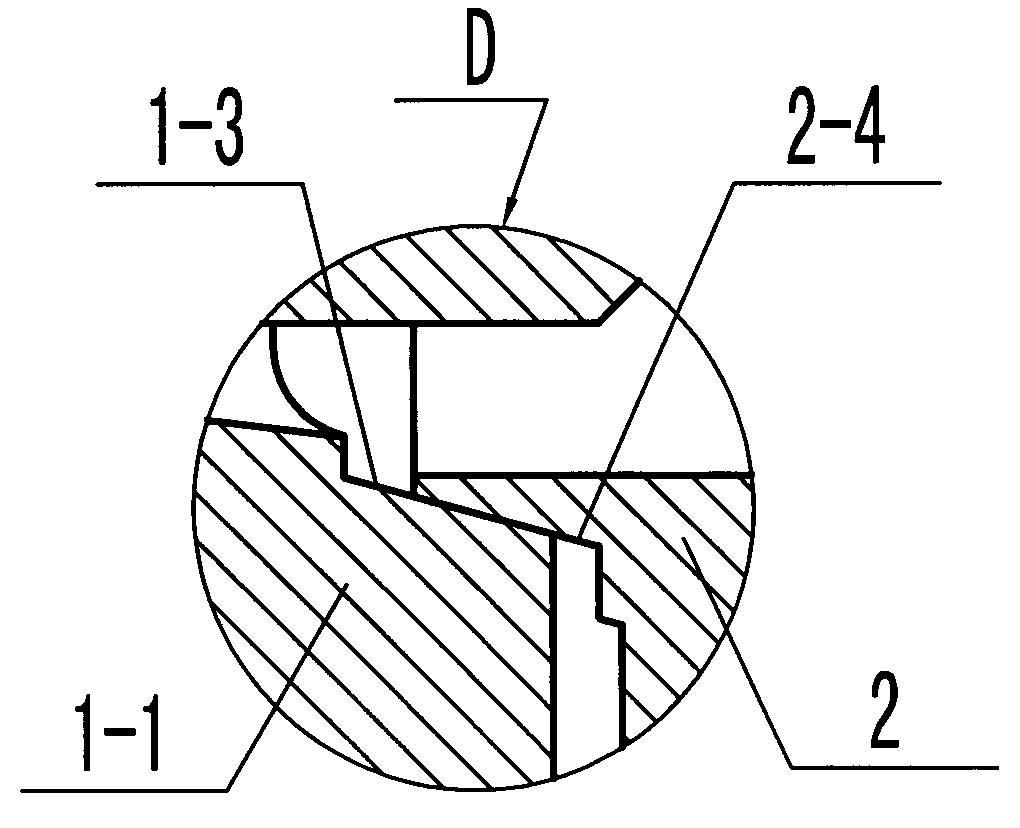

[0038] Depend on Figure 1 to Figure 3 It can be seen that the adjustable precision forged steel vise of the present invention includes a movable pliers body 1, a fixed pliers body 2, a screw rod 3, a guide rod 1-1, a nut 5, a driving rod 6, a countersunk socket head cap screw 7, a pressure plate 8, and a spring 4, of which:

[0039] figure 1 Shown is the front appearance of the present invention. Both the movable pliers body 1 and the fixed pliers body 2 are welded components and forged from steel, so the pliers body has the advantages of light weight, high strength, and convenient transportation.

[0040] The left and right sides of the fixed pliers body 2 are oppositely provided with a fixed pliers body side panel 2-3, and the bottom of the fixed pliers body side panel 2-3 is fixedly connected with two separate parts of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com