Multi-station spin welding platform

A rotary welding and multi-station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult to guarantee welding accuracy, high labor intensity of workers, large production site, etc., to reduce the number of workers Labor intensity, occupying less production space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

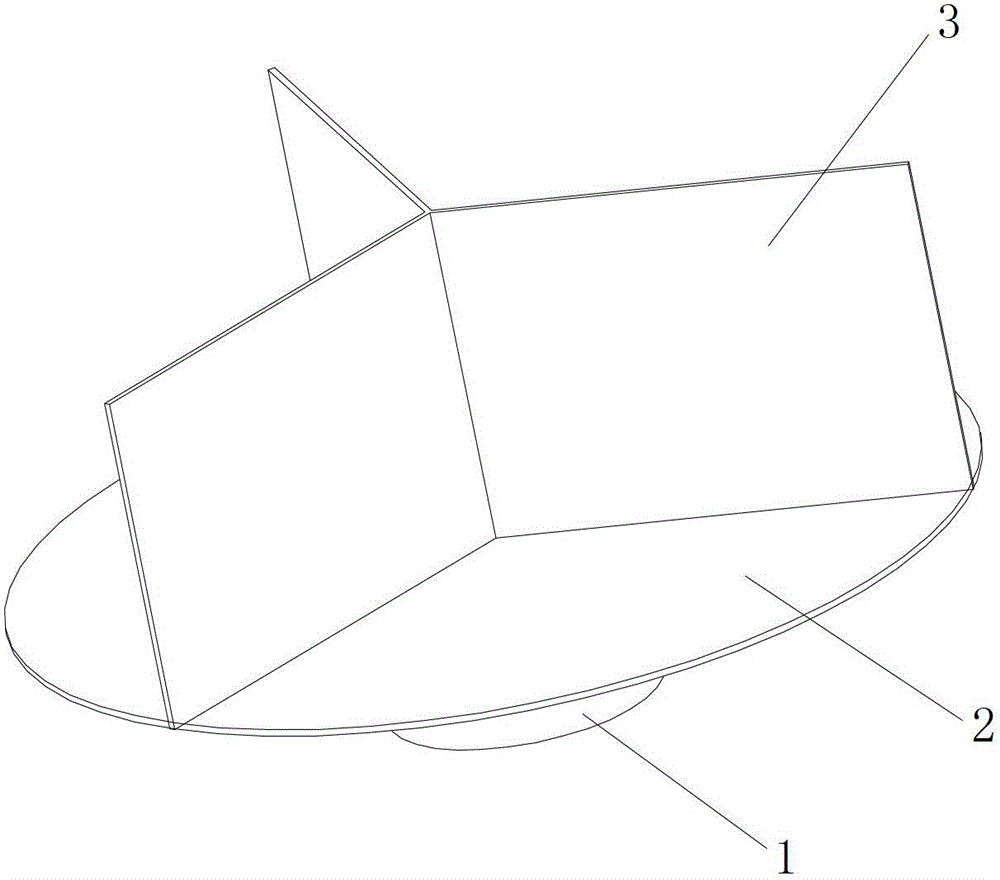

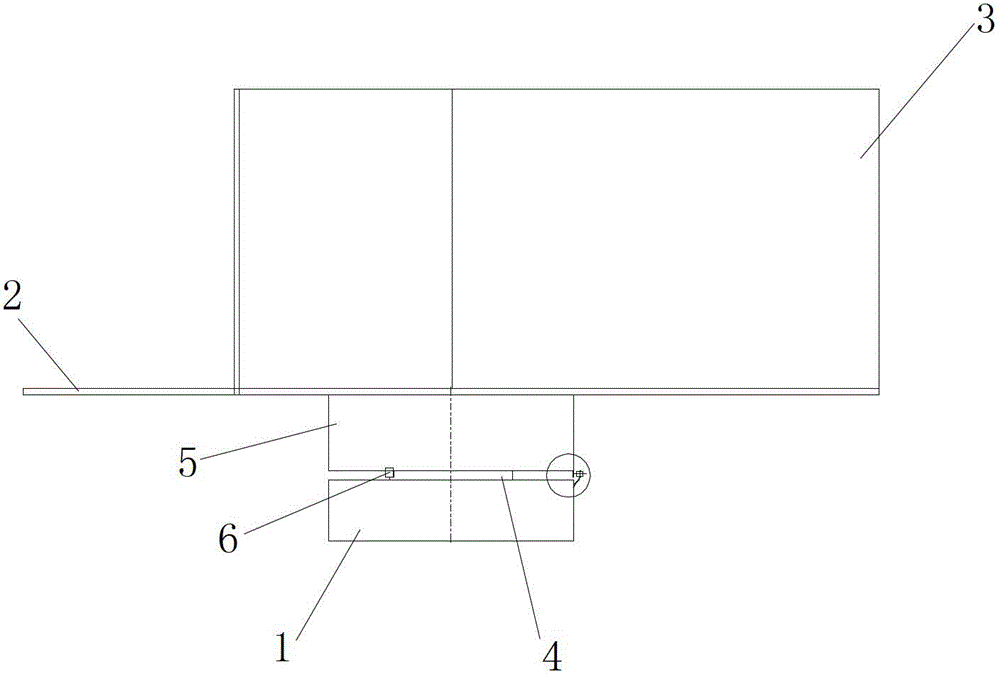

[0015] Such as Figure 1 to Figure 4 As shown, the multi-station rotary welding platform of the present invention includes a turntable base 1, a turntable shaft 4 connected to the turntable base 1, a turntable support connected to the upper end of the turntable shaft 4 and capable of rotating together with the turntable shaft 4 Seat 5, the tooling placement table 2 fixedly connected to the turntable support seat 5, the light-shielding grid plate 3 which is arranged on the tooling placement table 2 and divides the tooling placement table 2 into n equal parts, and the turntable base 1 is provided with a driving turntable The servo motor (not shown in the figure) that the rotating shaft 4 rotates protrudes from the lower side of the turntable support seat 5. There are n pieces of position detection plates 6, and one side of the turntable base 1 is connected with a position detection plate for detecting the lower side of the turntable support seat 5. The photoelectric detection sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com