Explosive welding least action charging method

An explosive welding and action technology, which is applied in welding equipment, non-electric welding equipment, special data processing applications, etc., can solve the problem that it is impossible to achieve successful explosive welding of composite plates, the amount of explosives used for explosive welding, and the interface quality of composite plates are not directly given. Problems such as not being in the best condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

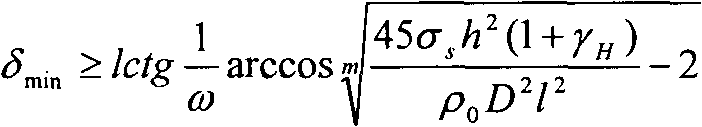

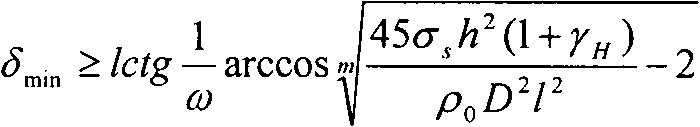

Method used

Image

Examples

Embodiment Construction

[0015] The user needs a batch of explosively welded 316L / 16MnR composite boards. Substrate size: 2000mm×10000mm×20mm; compound board size: 2000mm×10000mm×3mm. According to the law of the minimum charge, the minimum charge thickness is calculated to be 1.5mm; and according to the above-mentioned maximum distance rule, the maximum distance is determined to be 6mm. According to the above test results, the effect of explosive welding is the best, and the amount of charge is greatly reduced, which reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com