Electrode and machining method for electrolytic grooving of blisks

An integral blisk and groove machining technology, applied in electric machining equipment, electrochemical machining equipment, machining electrodes, etc., can solve the problems of uneven machining allowance, inability to achieve precision electrolytic machining without allowance, disadvantageous blade profile machining, etc. To achieve the effect of improving the grooving processing efficiency, good economic benefits, and uniform allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

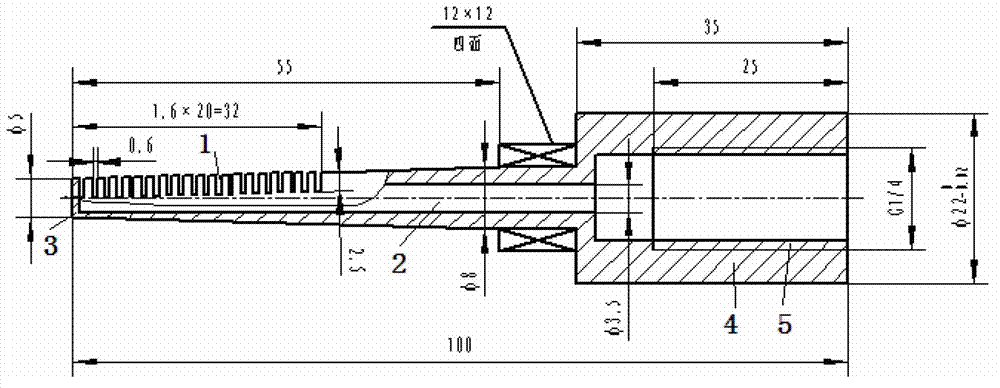

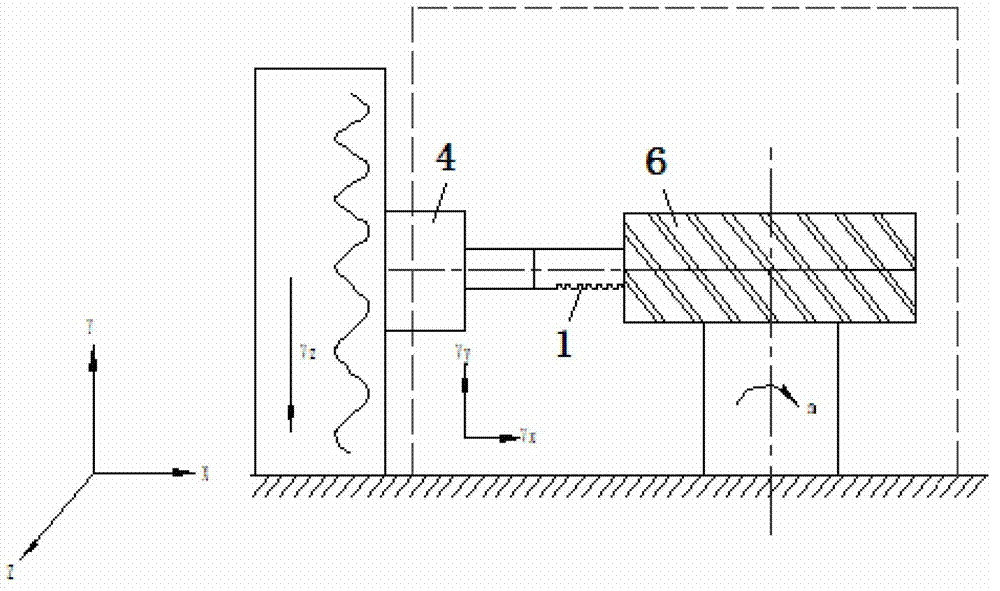

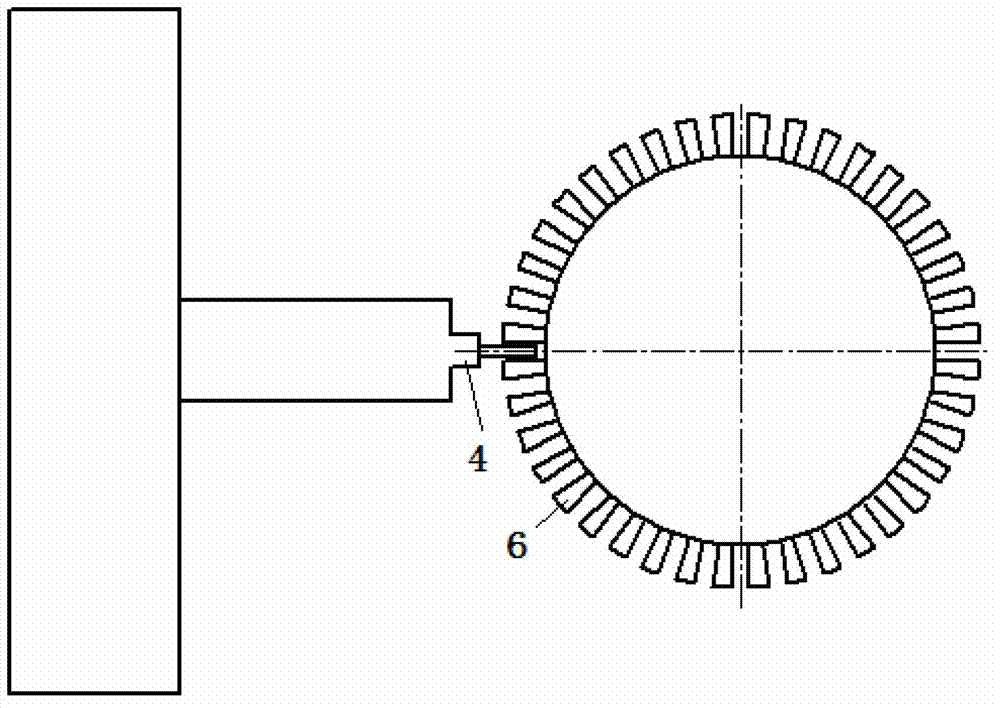

[0024] An electrode for electrolytic grooving of an integral blisk, characterized in that: the electrode for electrolytic grooving of an integral blisk is a hollow finger-like structure as a whole, and the hollow structure inside the electrode is mainly used as a channel for an electrolyte. There is a narrow groove 1 with a width of 0.6mm at intervals of 1mm along the circumferential direction 1 / 3-1 / 2 of the section of the fingertip ≤ 1 / 2 of the full length, so that the electrolyte can communicate through the narrow groove To the processing area; the inside of the electrode for electrolytic slotting of the integral blisk is provided with an electrolyte delivery pipeline 2; the finger end of the electrolyte delivery pipeline 2 near the processing section is provided with a plugging structure 3, so that the electrolysis The liquid delivery pipeline 2 is a blind hole structure, and the electrolyte can only flow out from the narrow groove 1 .

[0025] Under the action of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com