Demountable rectifying device of horizontal triphase separator

A three-phase separator and rectification device technology, which is applied in the direction of separation methods, immiscible liquid separation, chemical instruments and methods, etc., can solve the problems of no major improvement in flow characteristics, short length of flow, steady flow, and insufficient rectification obvious problems, to achieve the effect of easy manufacture, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

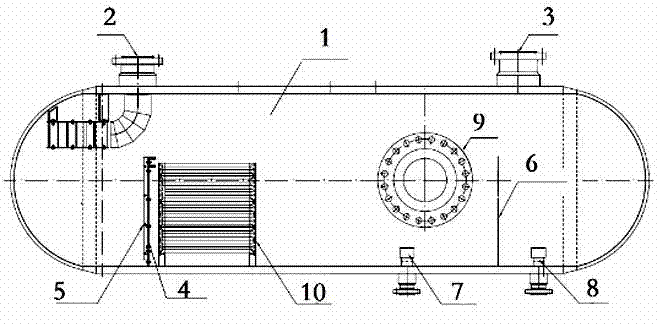

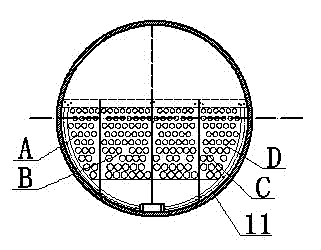

[0015] Such as figure 1 As shown, the separator of the present invention is a horizontal three-phase separator. The upper ends of the separator cavity 1 are respectively provided with an oil-gas-water inlet 2 and a gas outlet 3. The separator cavity 1 below the separator oil-gas-water inlet 2 is used as a ring-shaped fixing part 4 to connect with the rectification device 5. In the rectification A coalescer 10 is provided on one side of the device 5; a weir plate 6 is provided in the separator cavity 1 below the gas outlet 3. Both sides of the weir plate 6 are respectively provided with a water phase outlet 7 and an oil phase outlet 8 . In order to facilitate maintenance, a manhole 9 is also provided on the separator.

[0016] The working principle of the separator is: the oil-gas-water mixture enters the separator cavity 1 from the oil-gas-water inlet 2, along the figure 1 The medium flow direction flows through the rectifying device 5 so that unstable flow states such as...

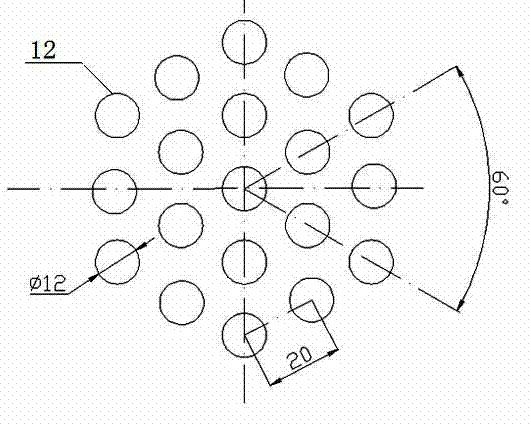

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com