Slaughtering installation and method

A technology of facilities and equipment, applied in the field of slaughtering facilities, which can solve the problems of high transmission speed, unslaughtered poultry, and different sizes of poultry, and achieve the effect of improving positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

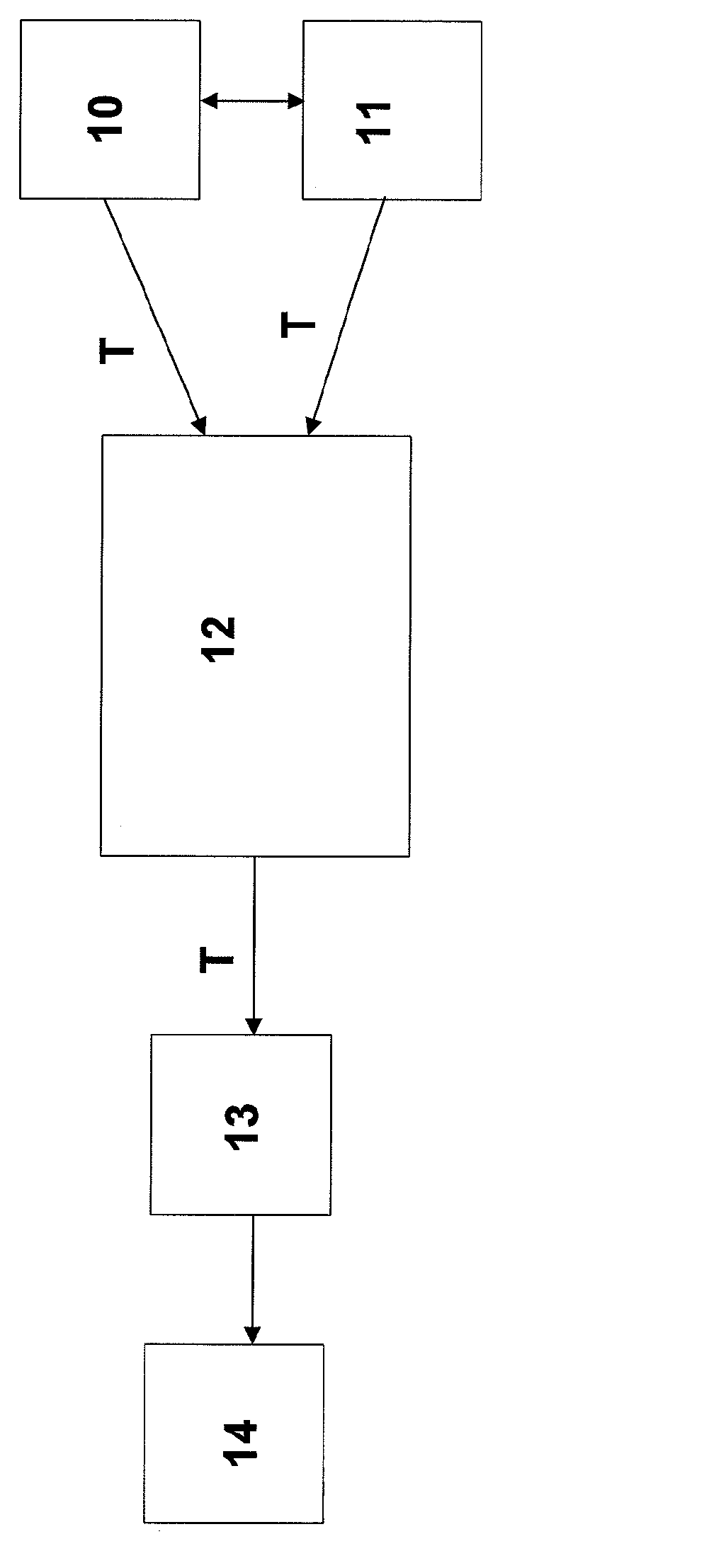

[0089] A part of a flow diagram for processing poultry is schematically shown in FIG. 1 . The schematic diagram shows parts of a facility for processing poultry in relation to a slaughter facility according to the invention. At station 10, the poultry were stunned. This can be done electrically or gaseously. At station 11, the birds are suspended by their legs on the conveyor assembly. Usually this is done manually. It is possible to stun first and then suspend the birds, or to suspend the birds first and then stun them. In either case, the transport assembly on which the poultry is suspended transports the poultry in the transport direction T to the slaughter facility 12 according to the invention.

[0090] For example, poultry are stunned at station 10 and then successively transferred to slaughter facility 12 . The facility 12 is suitable for use in combination with a conveyor assembly for conveying poultry in the transport direction T, from which the poultry's legs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com