Ultrathin rubber asphalt wearing layer mixing material for preventive conservation

A preventive maintenance, rubber asphalt technology, applied in the field of asphalt pavement preventive maintenance materials, can solve the problems of poor road performance, poor durability, no bearing capacity, etc., to achieve high compressive rebound modulus, excellent mechanics performance, the effect of high compressive strength

Active Publication Date: 2014-01-22

BEIJING MUNICIPAL ROAD & BRIDGE BUILDING MATERIALGRP +2

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0016] To sum up, due to the thin pavement thickness, although the existing ultra-thin wear layer can better play anti-skid and anti-wear functions, it basically has no bearing capacity, so it is mostly used for old road overlays , the functional layer of various new roads, and the surface layer of low-traffic and low-cost roads, which are susceptible to spalling and reflective cracks

And because the ultra-thin wear layer is only used as a material to improve the function of the road surface, its road performance is basically not paid attention to, resulting in poor road performance and poor durability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0047] Embodiment 1: coarse aggregate: fine aggregate: mineral filler: rubber asphalt=75:18:7:6.3

Embodiment 2

[0048] Embodiment 2: coarse aggregate: fine aggregate: mineral filler: rubber asphalt=75:18:7:6.2

Embodiment 3

[0049] Embodiment 3: coarse aggregate: fine aggregate: mineral filler: rubber asphalt=70:20:10:6.5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Login to View More

Abstract

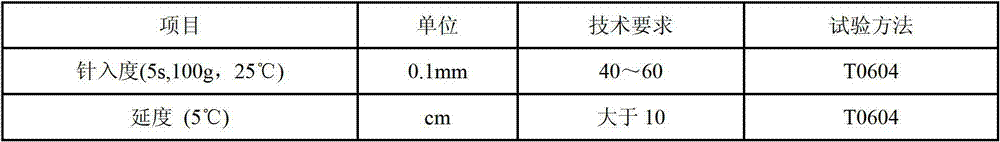

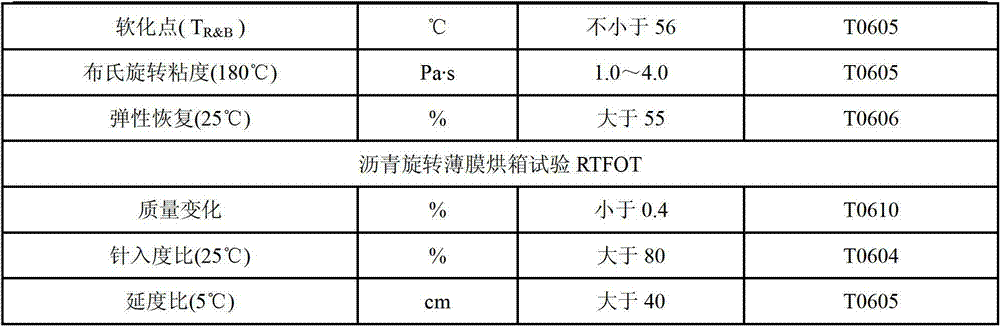

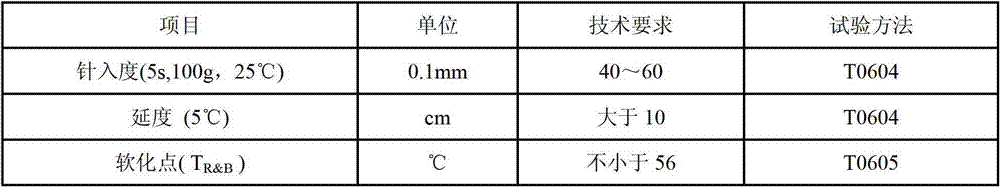

The invention relates to an ultrathin rubber asphalt wearing layer mixing material for preventive conservation, and belongs to the technical field of the manufacturing of road asphalt pavement materials. The mixture is prepared by blending the following components of a rubber asphalt binder and aggregates in a weight ratio of (6-7):100, wherein the rubber asphalt binder consists of rubber powder and asphalt serving as a matrix in a weight ratio of (15-25):100; and the aggregates are prepared from 5 to 10 millimeters of basalt coarse aggregates, fine aggregates and mineral fillings in a weight ratio of (70-80):(15-25):(5-10). The ultrathin rubber asphalt wearing layer mixing material has the characteristics of the skid resistance and abrasion resistance of ultrathin wearing layers made of other materials, can be used for the preventive conservation of high-grade road surfaces and ultrathin wearing layer materials for the corrective conservation of slight breakage, and also has the high road performance, mechanical property and durability, so that the possibility that the ultrathin rubber asphalt wearing layer mixing material is used as a road surface structural layer is ensured.

Description

technical field [0001] The invention is a material used for preventive maintenance of asphalt pavement, especially the preventive maintenance of high-grade asphalt or cement pavement and the corrective maintenance of minor diseases. It can be used as a pavement structure layer and belongs to the manufacture of road asphalt pavement materials. technology field. Background technique [0002] The so-called preventive maintenance of the pavement means that through regular road condition surveys, minor pavement damage and signs of disease can be found in time, the causes of the pavement can be analyzed and studied, and protective maintenance measures can be taken to prevent the further expansion of minor diseases, reduce the rate of pavement performance degradation, and keep the pavement in good condition all the time. service status, deferring costly overhauls and rebuilding projects to save on maintenance costs. Scientific road maintenance countermeasures should be "mainly pre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B26/26

Inventor 柳浩杨丽英董雨明王建国王真李振李恩光王宝新

Owner BEIJING MUNICIPAL ROAD & BRIDGE BUILDING MATERIALGRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com