High-pressure discharge lamp

A technology for high-pressure discharge lamps and discharge capacitors, which is applied in the direction of discharge lamps, gas discharge lamps, and parts of gas discharge lamps, and can solve problems such as short circuits and failure to realize the combination of auxiliary dischargers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

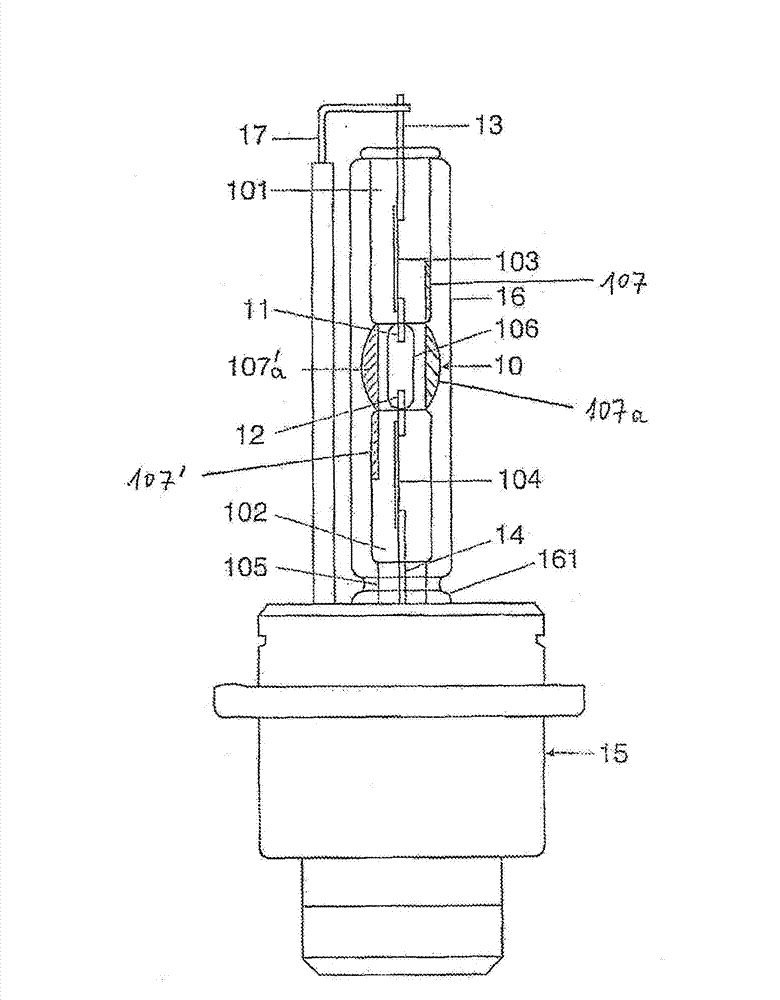

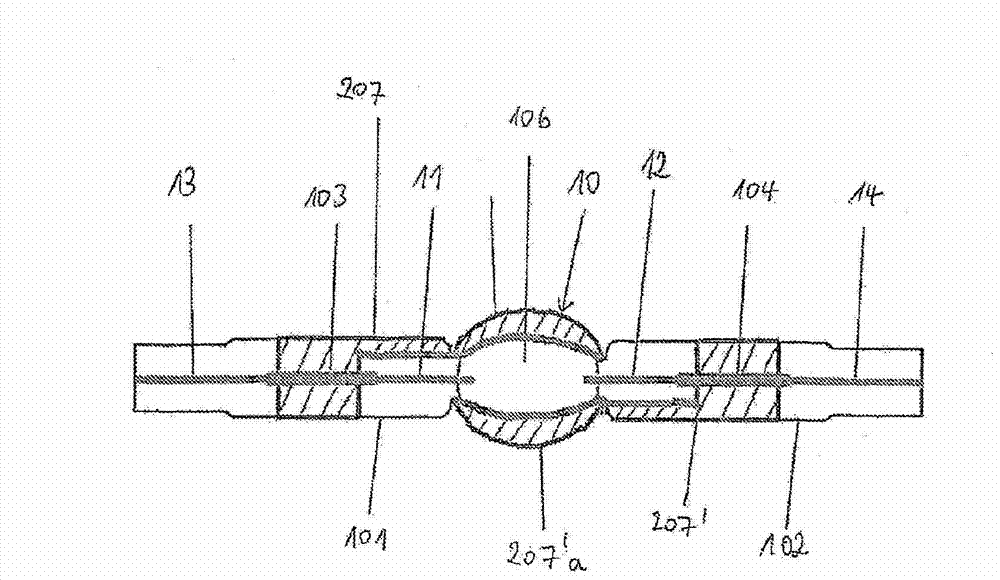

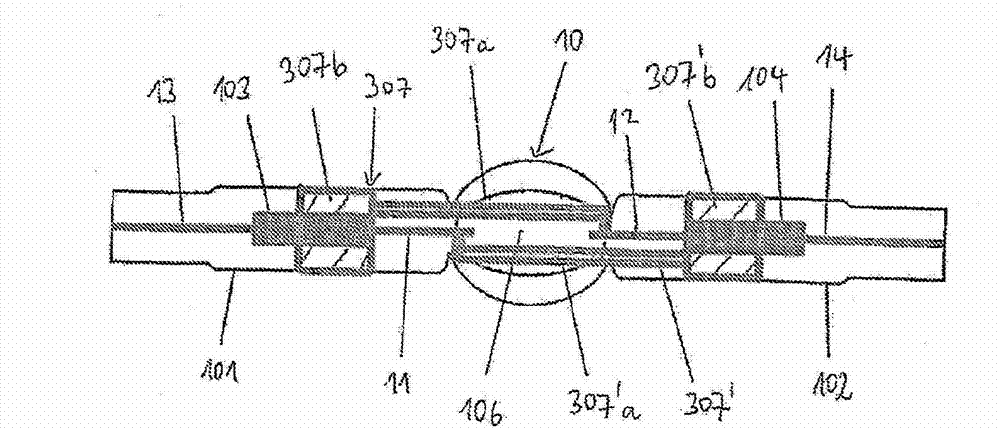

[0020] of the present invention figure 1 A first embodiment schematically shown in is a mercury-free halogen metal vapor high-pressure discharge lamp with an electrical power consumption of approximately 35 watts. The lamp is intended for use in a motor vehicle headlight. The lamp has a volume of 24mm 3 A discharge vessel 10 of quartz glass, sealed on both sides, in which is hermetically enclosed an ionizable filling made of xenon gas and halides of the metals sodium, scandium, zinc and indium composition. In the region of discharge space 106 , the inner contour of discharge vessel 10 is cylindrical and its outer contour is elliptical. The discharge space 106 has an inner diameter of 2.6 mm and an outer diameter of 6.3 mm. The two ends 101 , 102 of the discharge vessel 10 are each sealed by means of a molybdenum foil fusion 103 , 104 . Two electrodes 11 , 12 protrude into discharge space 106 of discharge vessel 10 , between which electrodes a discharge arc responsible for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com