Cam controller with mechanical limit, forced disconnection and dynamic monitoring functions

A cam controller and dynamic monitoring technology, applied in the direction of contact drive mechanism, etc., can solve the problems of poor reliability, output shaft breakage, safety accidents, etc., and achieve the effect of stable installation structure and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

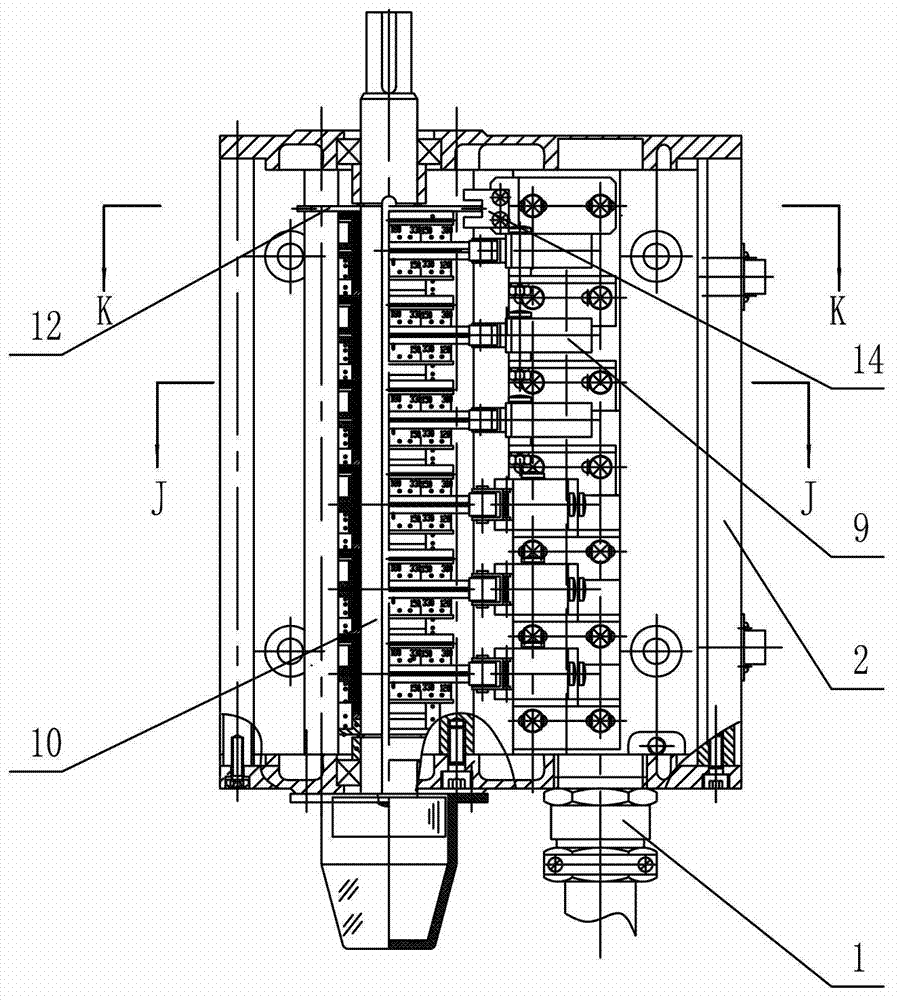

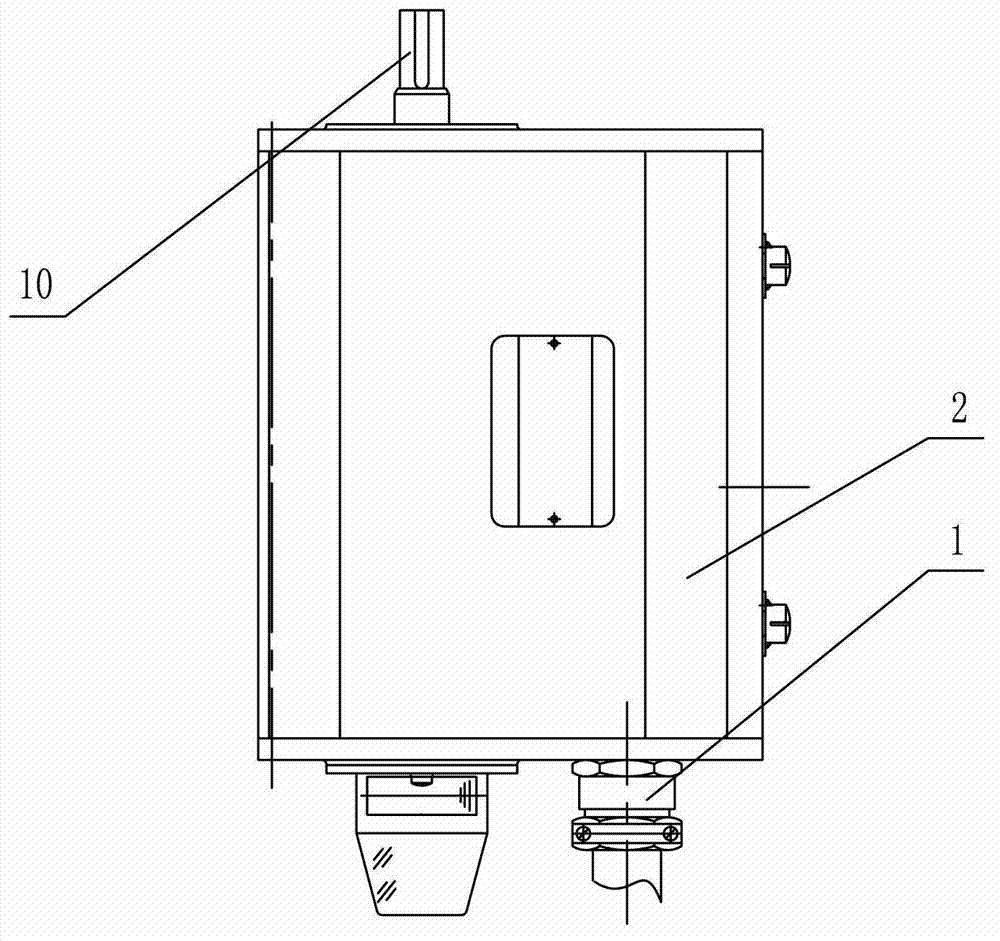

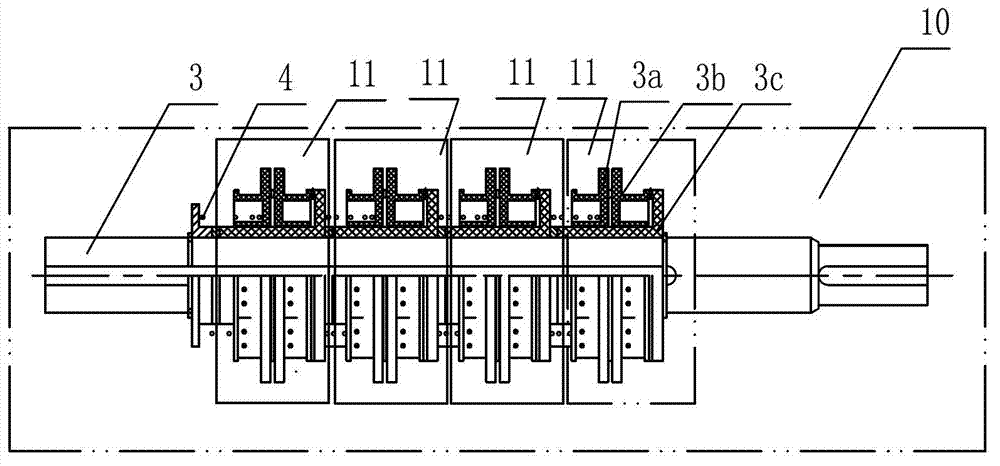

[0057] The present invention will be further described below in conjunction with specific drawings.

[0058] Such as Figure 1~Figure 30 Shown: The cam controller with mechanical limit, forced disconnection and dynamic monitoring includes cable terminal joint 1, controller cover 2, camshaft 3, compression spring 4, first limit device 5, second limit device 6. The third limit device 7, the fourth limit device 8, the switch 9, the camshaft assembly 10, the cam assembly 11, the code disc 12, the mounting bracket 13, the photoelectric sensor 14, the switch bracket 15, the resolver 16, the spring leaf 17. Coupling 18, output shaft 19, mounting flange 20, outer cam piece 3a, inner cam piece 3b, bushing 3c, first arc-shaped stopper 51, second arc-shaped stopper 61, third arc-shaped stopper Stopper 71, fourth arc-shaped stopper 81, first limit pin 52, second limit pin 62, first arc-shaped groove 72, second arc-shaped groove 82, third arc-shaped groove 53, fourth arc-shaped groove sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com