Integrated test stand of straight-travel electric actuating mechanism

An electric actuator and comprehensive testing technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of undetectable, limited measuring range, unavailable, etc., to achieve an improved level, simple and convenient testing The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

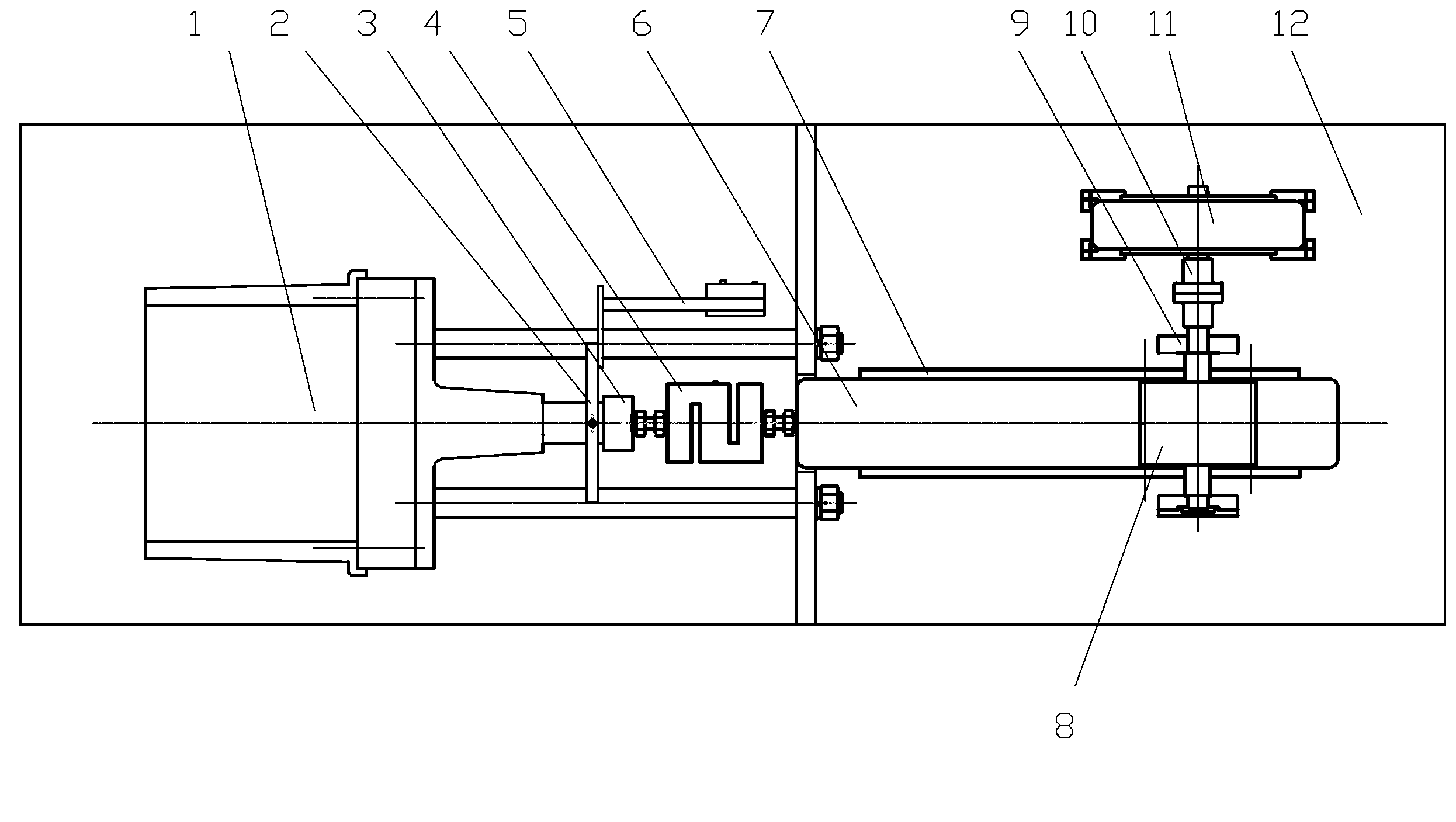

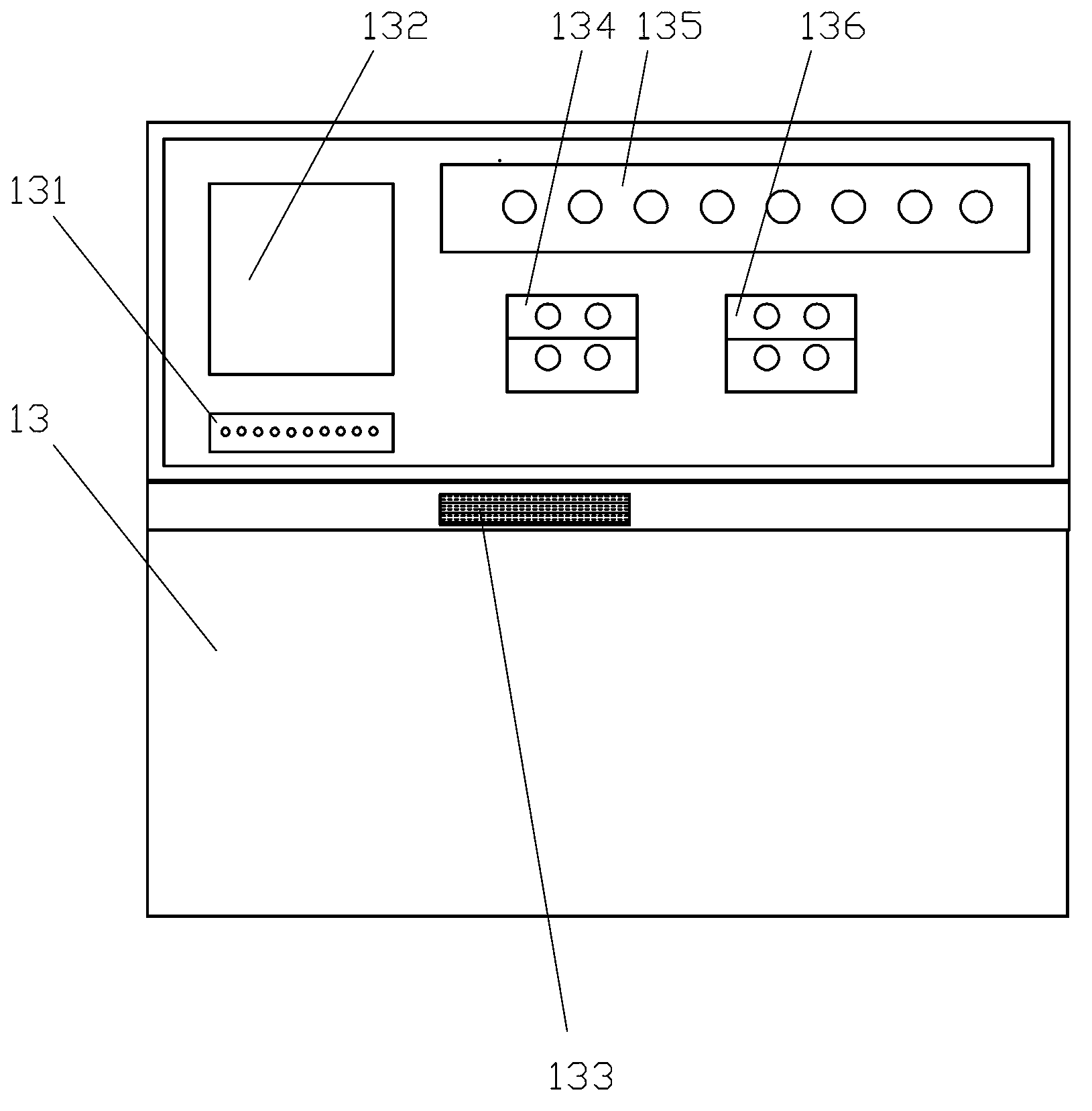

[0021] like figure 1 As shown, the comprehensive test bench for the straight-stroke electric actuator mainly includes an S-type force sensor 4 , a digital display displacement measuring instrument 5 , a magnetic powder brake 11 , a rack and pinion group, and a console 13 ; it also includes a mounting seat 12 .

[0022] One end of the S-shaped force sensor 4 is the connection end of the output shaft of the electric actuator; It runs on the rack seat 7, and the rack seat 7 is fixed on the mounting seat 12.

[0023] The gear 8 in the rack and pinion set that cooperates with the rack 6 is mounted on a gear shaft, the end of the gear shaft is supported on the bearing seat 9, and the bearing seat 9 is fixed on the mounting seat 12 ; The gear shaft is connected with the output shaft of the magnetic powder brake 11 through the coupling 10 .

[0024] The measuring end of the digital display displacement measuring instrument 5 is correspondingly connected with the output shaft 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com