A New Type of Car Shift Lever

A new type of technology for car gear shifting, applied in the field of auto parts, can solve the problems of single function and inconvenient placement of safety hammers, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

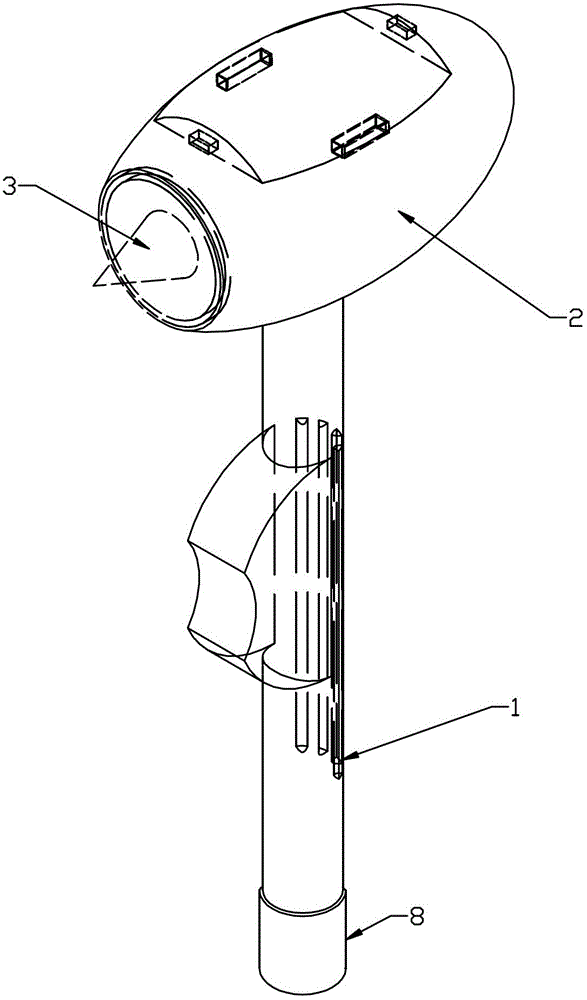

[0014] like figure 1 The present invention shown is a new type of automobile shift lever, which includes a rod body and a handle. The handle and the rod body form a hammer-shaped structure. One side of the handle is provided with a hard tip. The core 7 and a connecting sleeve 8 threadedly connected with the lower end of the rod body. The transmission needs to be equipped with a rod, which is provided with a socket matching the above-mentioned square prism, and the outer side of the rod is provided with an external thread matching the internal thread of the above-mentioned connecting sleeve. The hammer-shaped structure of the handle and the rod body means that the handle is equivalent to the hammer head of the hammer, and the rod body is equivalent to the handle of the hammer, forming a T-shaped structure. The rod body is connected to the transmission through a quick-connect joint. Remove the gear lever and use it as a safety hammer, smashing the glass with the hard point.

Embodiment 2

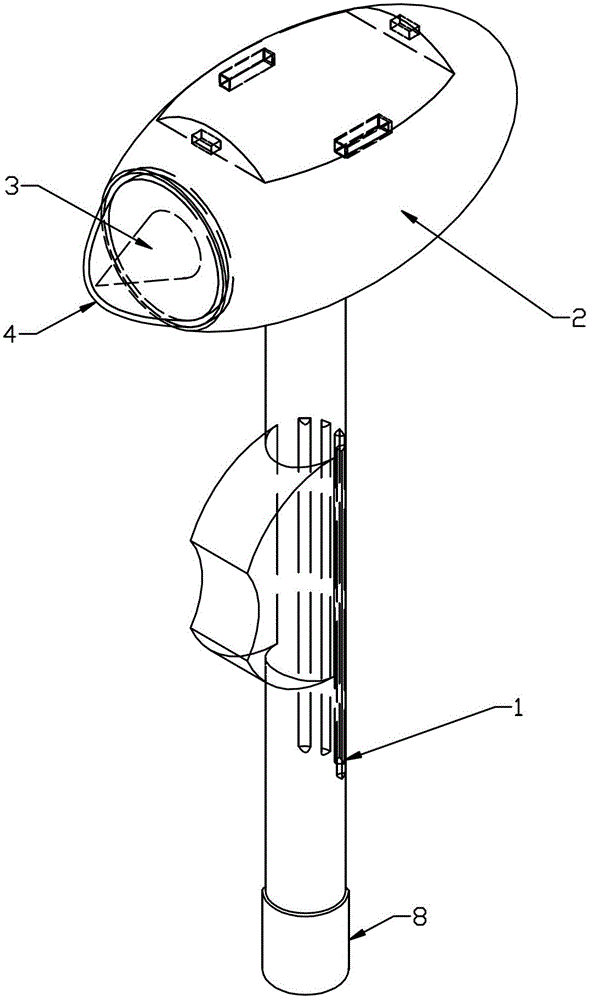

[0016] like figure 2 Shown, the present invention is a kind of novel automobile shift lever, comprises rod body 1, handle 2, and handle is provided with a brittle cover 4, and described handle and rod body constitute hammer-shaped structure, and handle is provided with the end of brittle cover. There is a hard tip 3, and the hard joint 3 is arranged inside the brittle cover 4. The lower end of the rod body is provided with a quadrangular prism ferrule 7 and a connecting sleeve 8 threadedly connected with the lower end of the rod body. The transmission needs to be equipped with a rod, which is provided with a socket matching the above-mentioned square prism, and the outer side of the rod is provided with an external thread matching the internal thread of the above-mentioned connecting sleeve.

[0017] The brittle cover prevents the hard pointed tip from causing damage to the occupant during normal use. When the shift lever is used as a safety hammer, the brittle cover is sma...

Embodiment 3

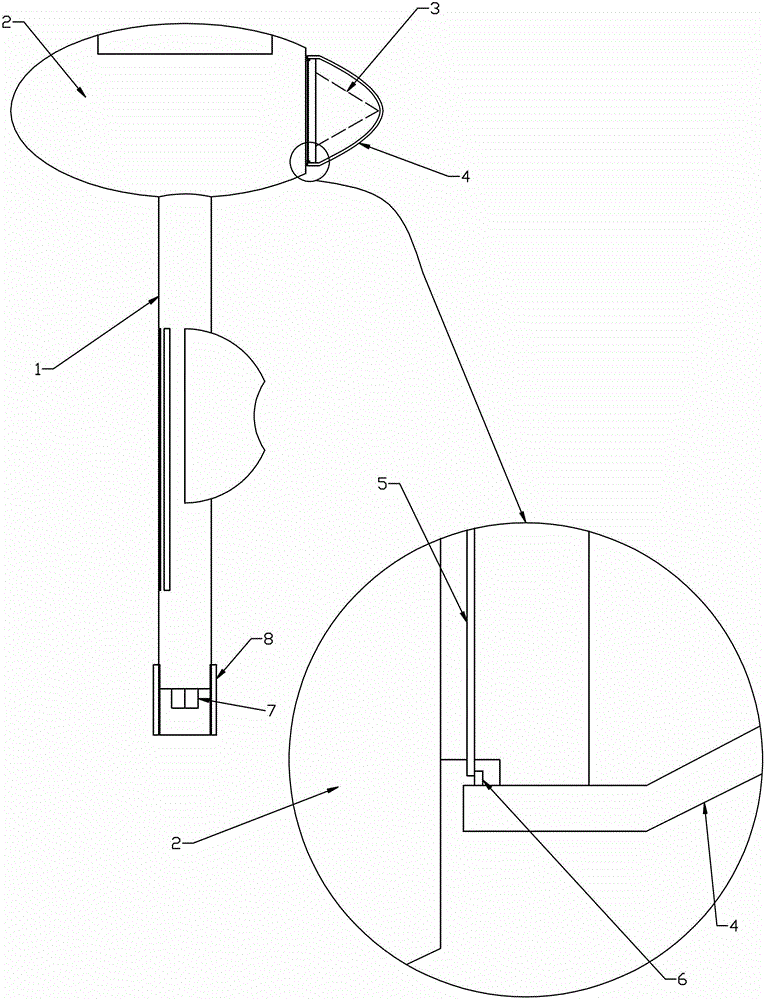

[0019] like image 3 As shown, on the basis of Example 1, the brittle cover of the present invention is socketed with the handle, and the handle 2 is provided with a limit ring 5 on the outer circle of the socket end of the brittle cover 3, and the brittle cover is connected to the A limit protrusion 6 is provided on the inner circle of the handle joint, and the limit protrusion and the limit ring fit together.

[0020] When the shift lever is used as a safety hammer, the brittle cover is first smashed against the glass of the car. During the collision process of the brittle cover, the limit protrusion destructively breaks through the limit of the limit ring, so that the brittle cover and the hard pointed A direct impact breaks the brittle cover, exposing the hard prong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com