Ball valve type mortar pump

A mortar pump and ball valve technology, applied in the field of mortar pumps, can solve the problems of uneven coating, low operation efficiency, short wear life and other problems, and achieve the effects of good conveying continuity, wide practicability and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

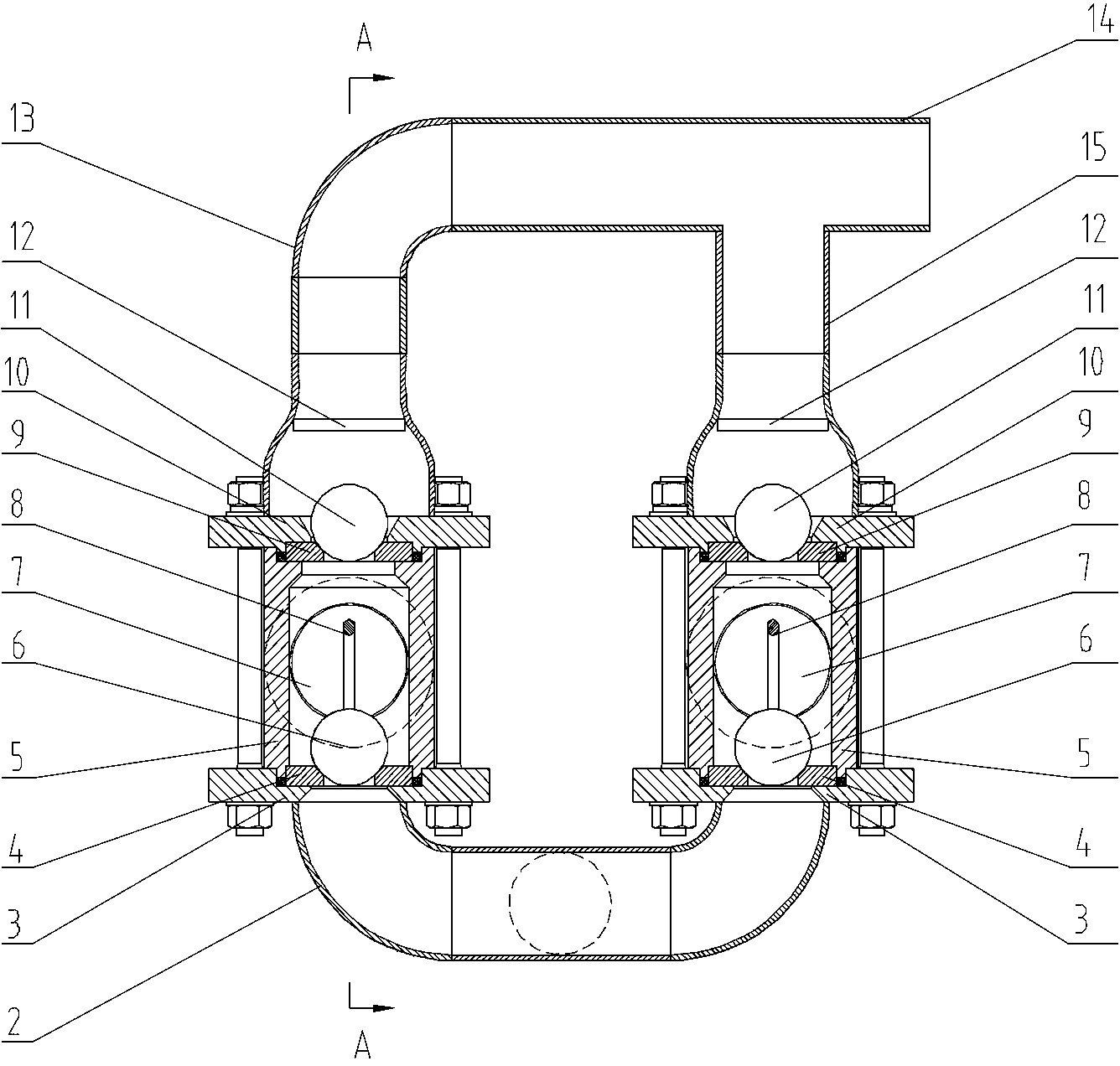

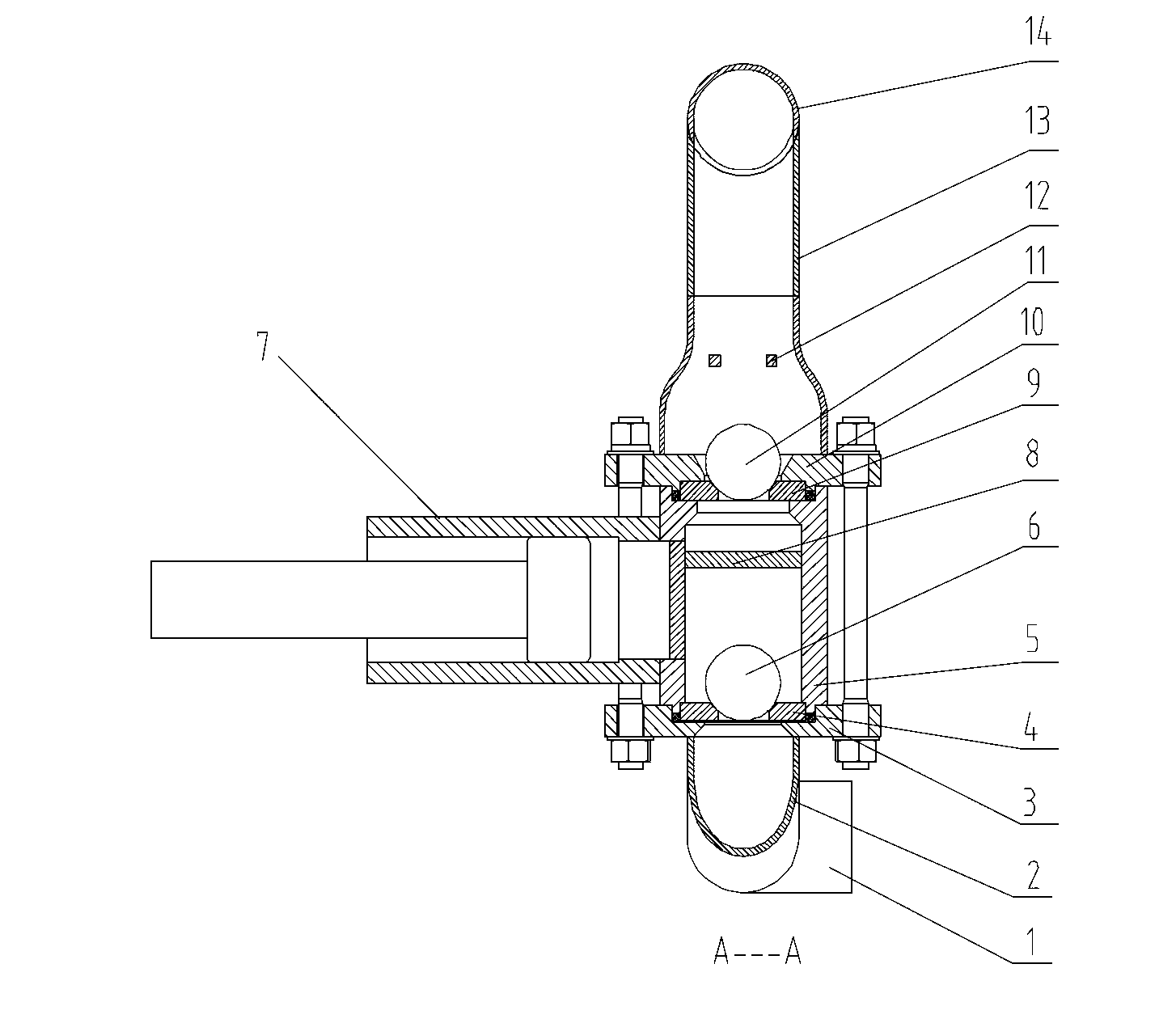

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0011] Such as figure 1 As shown, the ball valve type mortar pump of the present invention mainly consists of a feed pipe assembly, two left and right ball valves, two left and right delivery cylinders 7 and a discharge pipe 14. The feeding pipe assembly includes feeding pipe 1 and feeding pipe 2. The feeding pipe 2 is welded into one by three sections of left curved pipe, middle straight pipe and right curved pipe. The lower fixing plates 3 of the two ball valves are connected by welding, a radial hole is opened in the middle part of the pipe wall of the straight pipe, and the feed pipe 1 is vertically welded at the radial orifice position in the middle part of the straight pipe. The left and right ball valves have the same structure, and each ball valve includes a lower fixing plate 3, a lower ball valve seat 4, a valve body 5, a lower ball valve core 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com