Electroslag arc-starting smelting method by multiple granular reducing slag by electroslag furnace

A smelting method and electroslag furnace technology are applied in the field of reducing slag and liquid slag arc smelting process to achieve the effects of reducing investment, improving the quality and yield of steel ingots, and protecting water tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Electroslag furnace preparation:

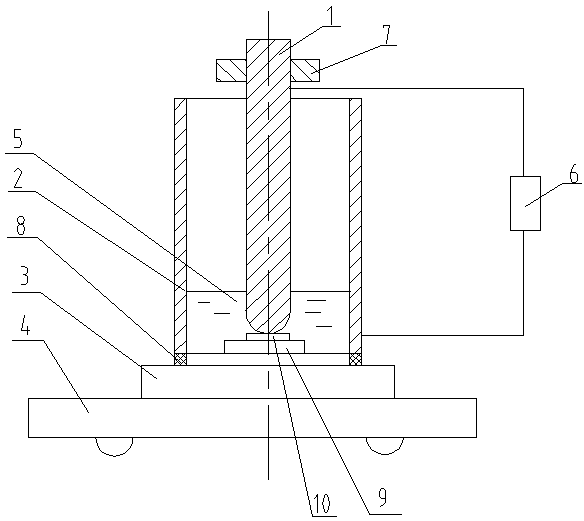

[0016] like figure 1 As shown, a sealed water tank 3 is placed on the trolley 4, and circulating cooling water is introduced into the water tank 3 to cool the molten slag in the crystallizer 2.

[0017] A crystallizer 2 is placed above the water tank 3, and an annular asbestos gasket 8 is placed between the water tank 3 and the crystallizer 2.

[0018] Prepare a set of DC power supply 6 with adjustable voltage, fix one of its two output ends on the metal self-consumable electrode 1 with the electrode chuck 7 , and fix the other end on the crystallizer 2 .

[0019] 2. Prepare dry multi-component mixed particles:

[0020] Weigh CaF according to the weight percentage ratio of 48%, 22%, 20%, 0.8%, 3%, 5% and 0.15% respectively 2 、Al 2 o 3 , CaO, SiO 2 、TiO 2 , MgO and FeO, after being fully mixed, set aside.

[0021] Three, smelting process steps:

[0022] 1. Place an arcing backing plate 9 on the inner bottom of the cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com