Static emulsification-pumped latex matrix on-line continuous sensitized emulsion explosive manufacturing process

A technology of latex matrix and manufacturing process, applied in the direction of explosive processing equipment, explosives, offensive equipment, etc., can solve the problems of loss of explosive performance, damage, increase, etc., and achieve the effect of improving intrinsic safety, increasing production capacity, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

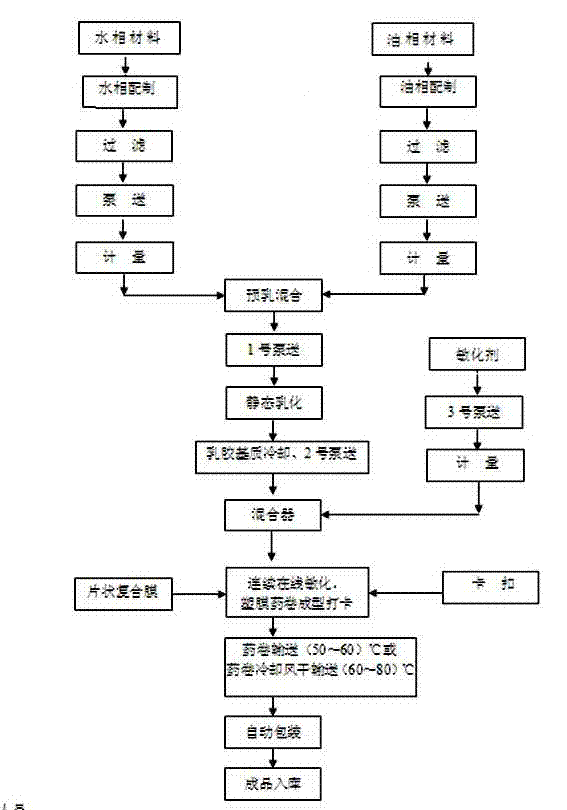

[0023] Static emulsification pumping latex matrix online continuous sensitized emulsion explosive manufacturing process, the process includes the following process steps:

[0024] A. Water phase liquid preparation, composite oil phase preparation;

[0025] B. Pre-emulsion mixing and static emulsification process: send the water phase liquid and the composite oil phase into the pre-emulsion for mixing, and send them to the static emulsifier through the No. 1 pump for emulsification to form a latex matrix;

[0026] C. cooling process; the latex matrix is cooled to 50-80 ℃ by cooling the steel belt;

[0027] D. Latex matrix pumping process; No. 2 pump continuously pumps the latex matrix cooled to 50-80°C to the sensitizer dispersion process;

[0028] E. Mixing process; the sensitizer is pumped into the mixer through the No. 3 pump, and is evenly dispersed into the 50~80°C latex matrix without detonator sensitivity; after 2-3 seconds, the latex matrix is still without The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com