Device for monitoring out-of-control falling of lifting equipment

A lifting device, No. 1 technology, applied in the direction of lifts, transportation and packaging, etc., can solve the problems of large consumption of materials, complicated installation, high cost, etc., and achieve the effect of low cost, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

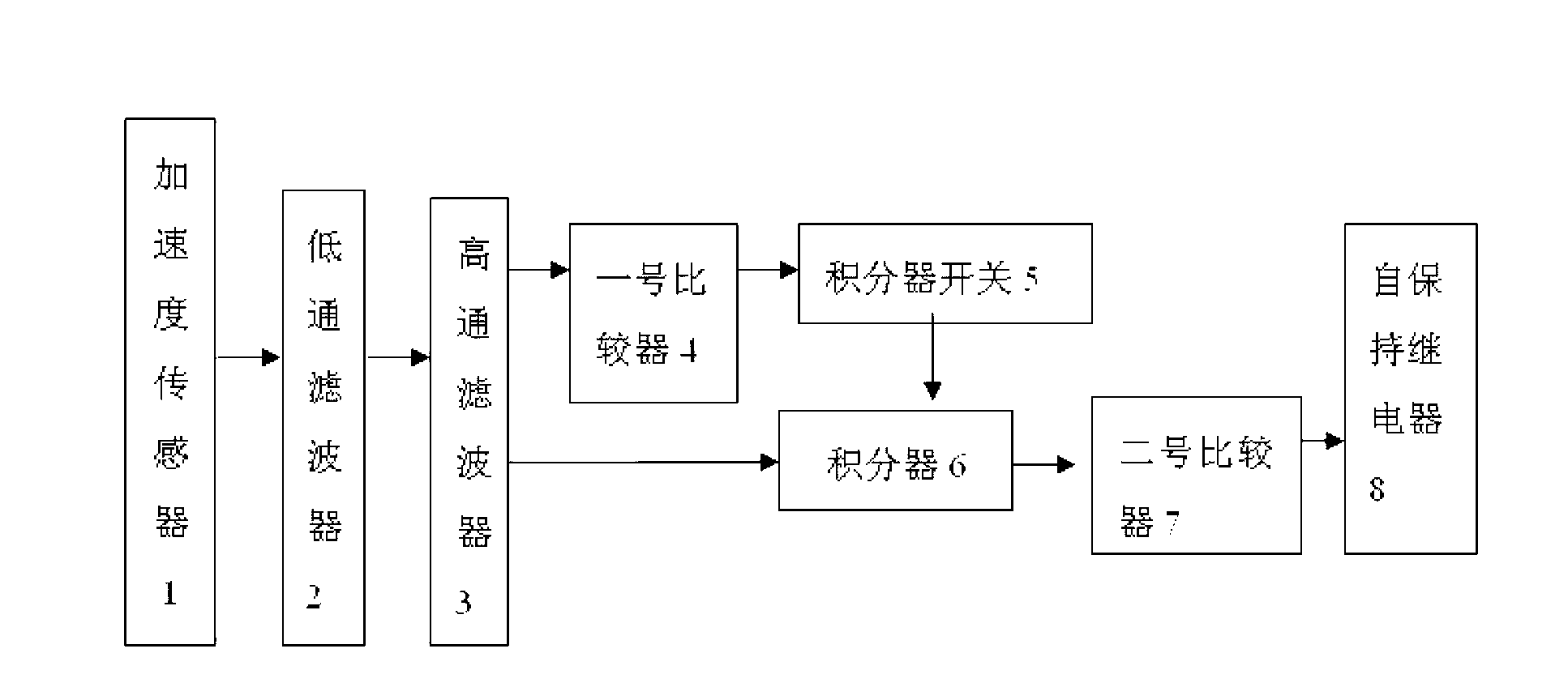

Embodiment 1

[0021] Such as figure 1 As shown, the device for monitoring the uncontrolled fall of lifting equipment provided in this embodiment includes an acceleration sensor 1, a low-pass filter 2 for filtering out high-frequency components, a high-pass filter 3 for filtering out DC and temperature drift signals, and a No. 1 Comparator 4, integrator 6, No. 2 comparator 7 and the self-holding relay 8 of locking fault state, the output end of described acceleration sensor 1 is connected with the input end of low-pass filter 2, the output end of low-pass filter 2 Connected to the input terminal of the high-pass filter 3, one output of the high-pass filter 3 is connected to the integrator 6 through the first comparator 4, the other output is directly connected to the integrator 6, and the output terminal of the integrator 6 is connected to the second comparator 7 is connected to the input end, the output end of the second comparator 7 is connected to the input end of the self-holding relay 8...

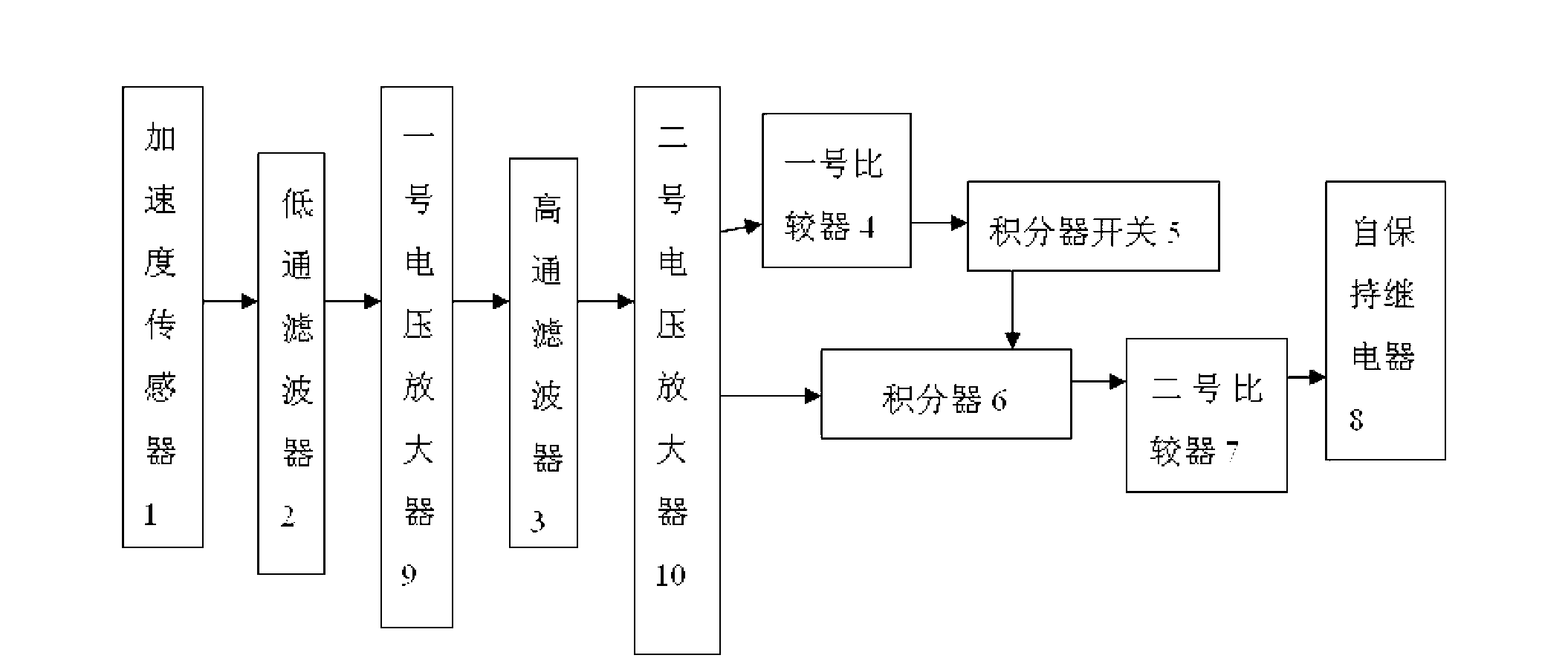

Embodiment 2

[0025] Such as figure 2 As shown, the difference between the device for monitoring the uncontrolled fall of lifting equipment provided in this embodiment and the embodiment 1 is only that a voltage amplifier 9 is connected in series between the low-pass filter 2 and the high-pass filter 3, and the The second voltage amplifier 10 is connected in series behind the high-pass filter 3; the rest of the content is the same as that described in Embodiment 1.

[0026] The working process of the device for monitoring the uncontrolled fall of lifting equipment described in this embodiment is as follows:

[0027] After the output signal of the acceleration sensor 1 is filtered by the low-pass filter 2 to remove high-frequency components, it is amplified by the No. 1 voltage amplifier 9, and then the high-pass filter 3 is used to filter out the DC and temperature drift signals to obtain a pure signal of the reaction acceleration; the pure The signal enters the No. 1 comparator 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com