Injection molding production technique of IML (In Mold Labelling) ultrathin workpieces

A production process and technology for ultra-thin parts, applied in the field of IML ultra-thin part injection molding production process, can solve the problem of inability to form products with qualified thickness, and achieve the effect of solving the problems of concave deformation and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

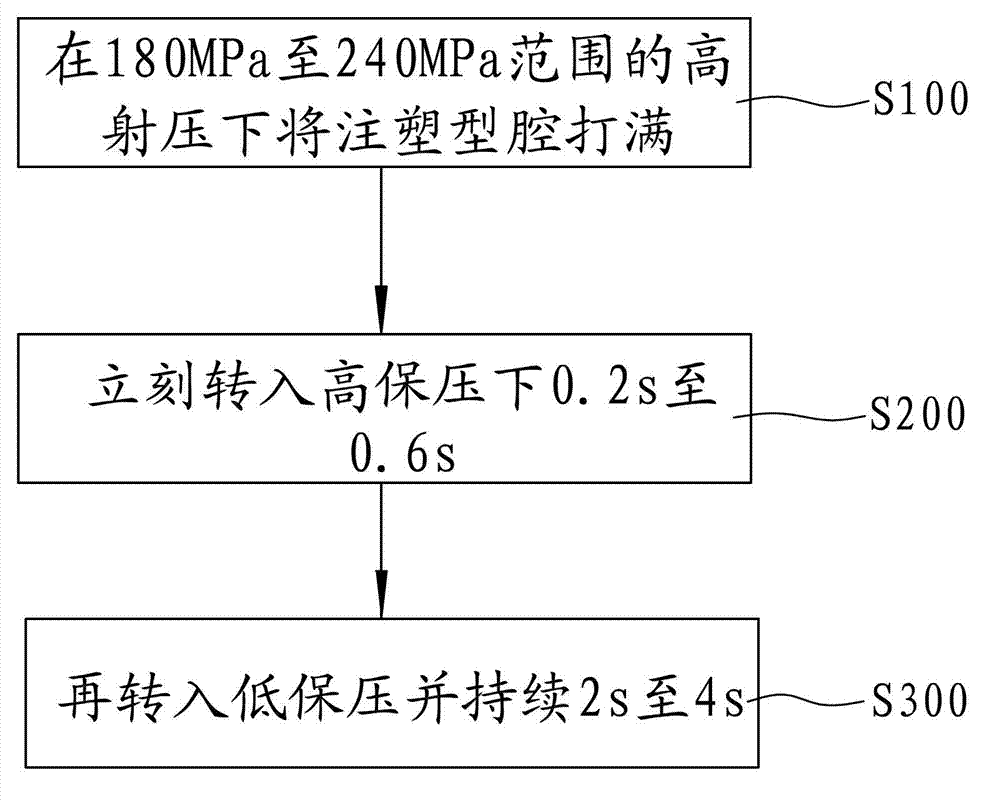

[0014] Such as figure 1 Shown, a kind of IML ultra-thin part injection molding production technique that the present invention relates to, it comprises the steps:

[0015] S100: Fill the injection cavity to the full under the high injection pressure ranging from 180MPa to 240MPa;

[0016] S200: Immediately switch to high holding pressure for 0.2s to 0.6s;

[0017] S300: Then switch to low holding pressure and last for 2s to 4s.

[0018] Preferably, in step S200, the pressure of the high holding pressure is in the range of 170MPa to 190MPa; and in step S300, the pressure of the low holding pressure is in the range of 40MPa to 65MPa.

[0019] In step S100, if the injection pressure is less than 180MPa, the fluidity of the injection molding liquid will become poor at this time, so that the flatness of the forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com