A combined welding stand

A combined, welding-position technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the labor intensity of welders, difficult to ensure the training effect, and increasing the work intensity, and achieve convenient installation and Welding operation, improving training assessment effect, saving training space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

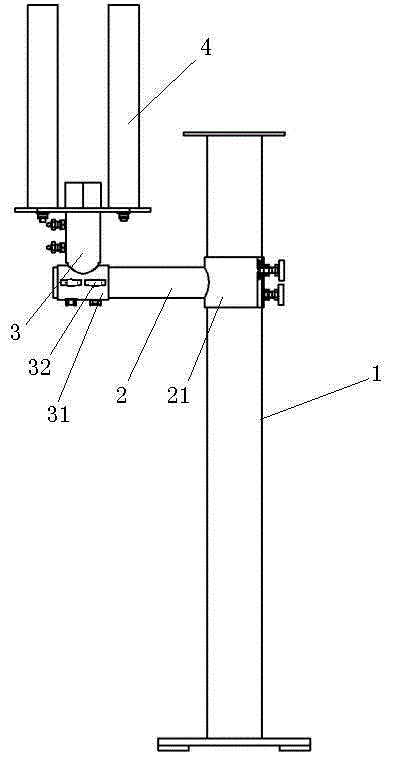

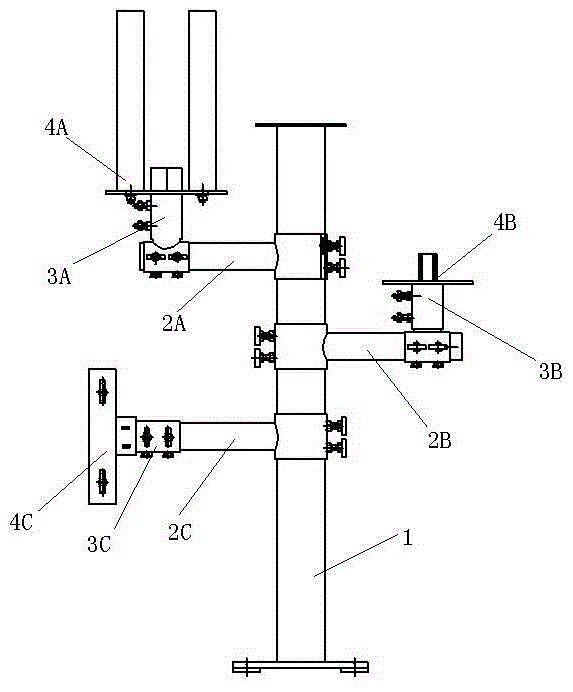

[0016] Such as figure 1 A combined welding position frame shown includes a column 1, and a welding position mechanism is provided on the column 1. The welding position mechanism includes an arm 2, and the arm 2 is positioned by a height provided on the column 1. The hole and the column 1 are fixed by bolts; the other end of the arm 2 is provided with a movable rod 3 , and the other end of the movable rod 3 is fixedly connected with a clamp 4 . One end of the arm 2 is provided with a sliding sleeve 21, and the arm 2 is movably sleeved on the column 1 through the sliding sleeve 21. The sliding sleeve 21 is provided with a bolt hole corresponding to the height positioning hole. One end of the movable rod 3 is provided with a sleeve 31, and the sleeve 31 is provided with an angle positioning hole 32. The movable rod 3 is movably sleeved on the arm rod 2 through the sleeve 31 and fixed by bolts through the angle positioning hole 32. The clamp 4 is a small-diameter tube cross barri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com