Novel roller brush

A technology of roller brush and roller, which is applied in the direction of coating, the device for coating liquid on the surface, etc. It can solve the problems of easy dripping of paint on the painter's body or the ground, waste of paint and manpower, pollution, etc., and achieves good application prospects , reduce waste, avoid the effect of dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

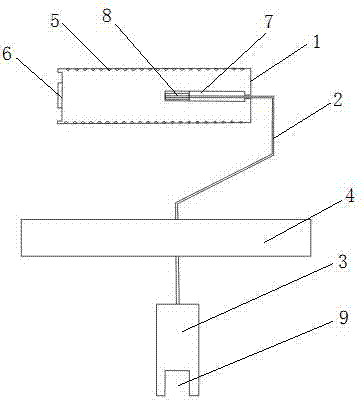

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a new type of roller brush includes a roller brush head 1, a connecting rod 2 and a handle 3. A receiving device 4 is arranged on the connecting rod 2, and the receiving device 4 is located below the roller brush head 1. During the painting process, it is used for Receive the paint dripping from the roller brush head 1, prevent the paint from dripping onto the painter's body or the ground, and avoid pollution and waste. The circular outer wall of the roller brush head 1 is provided with several evenly distributed discharge ports 5, and the roller brush head 1 is provided with a feeding cover 6, and the other side of the roller brush head 1 is provided with an installation cavity 7, and a slot connector 8 is provided in the installation cavity 7, and one end of the connecting rod 2 is stuck in the slot connector 8, And the connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com