A conditioning and granulating device for shrimp feed

A shrimp feed and tempering technology, which is applied in the field of conditioning and granulating equipment for shrimp feed, and the field of conditioning and granulating devices. It can solve the problems of insufficient moisture in conditioning and tempering, short curing time, and different appearance products, and achieve uniform appearance. , full heat absorption and moisture absorption, consistent color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

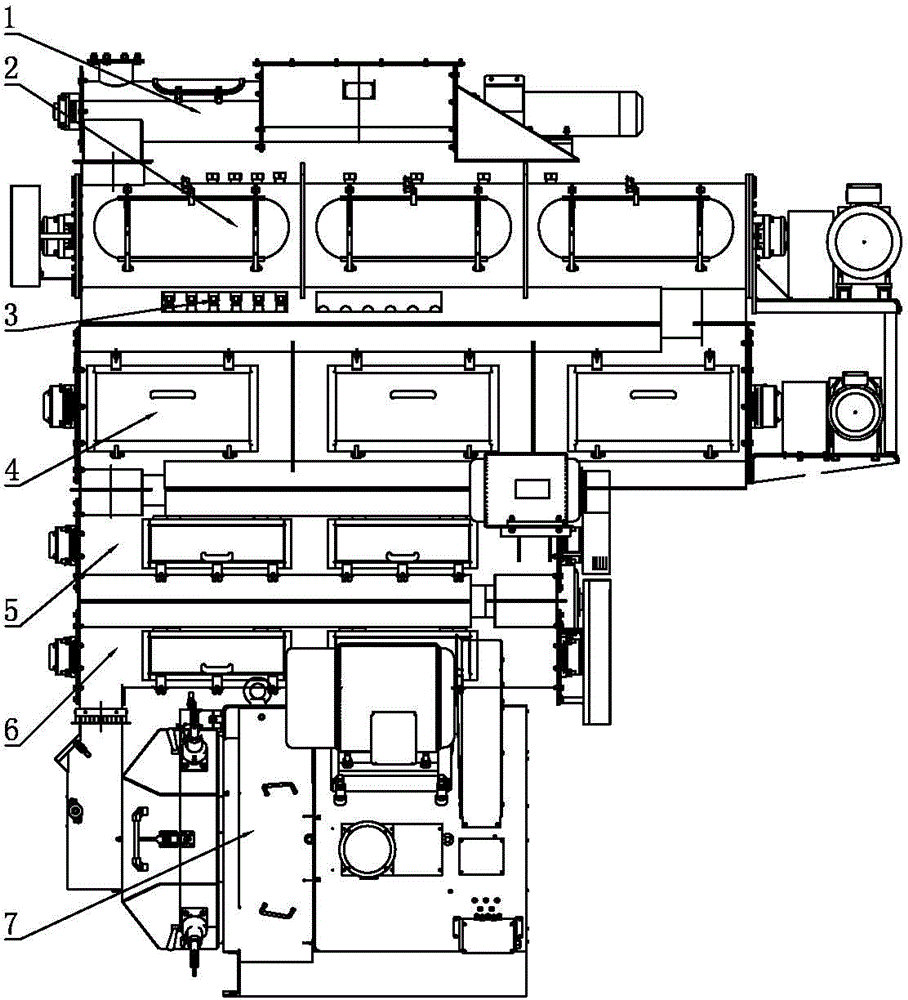

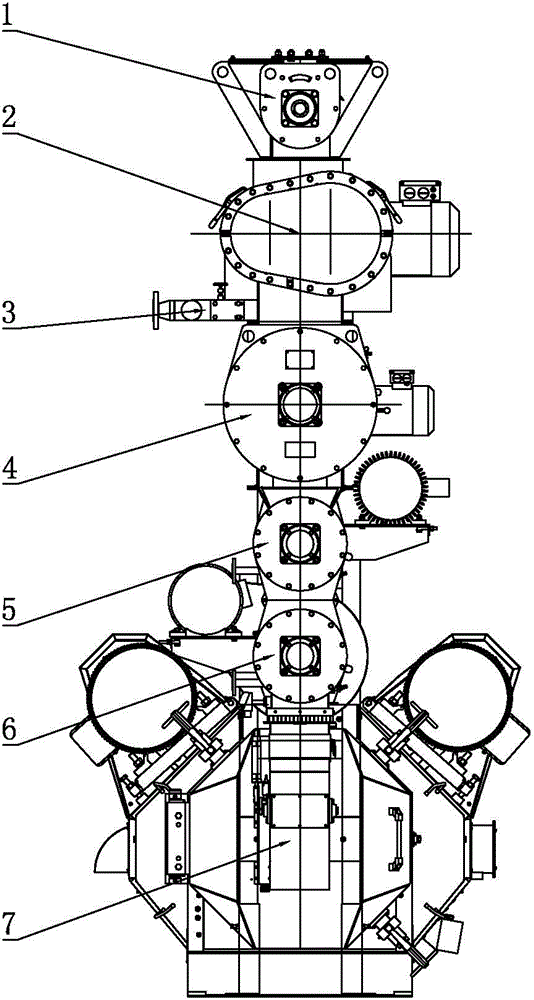

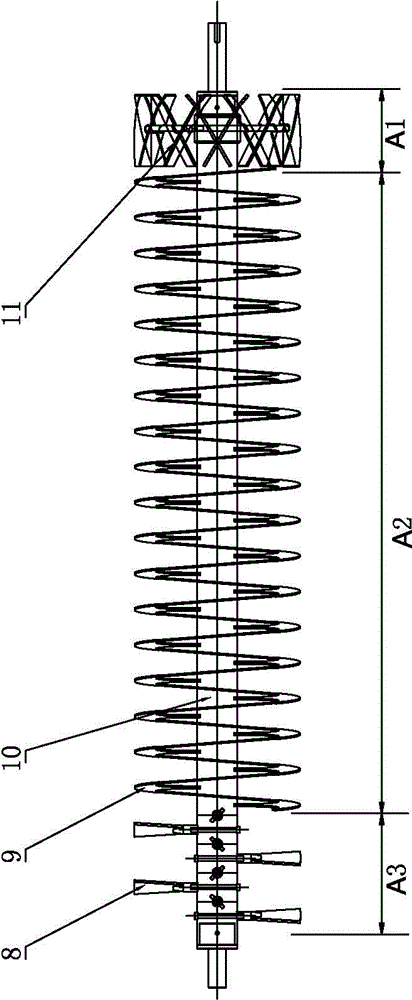

[0026] Such as figure 1 -6, is a conditioning and granulating device for shrimp feed. The discharge port of the feeder 1 is connected to the feed port of the conditioner 2, the discharge port of the conditioner 2 is connected to the feed port of the quality preservation device 4, and the discharge port of the quality preservation device 4 is connected to the feed port of the improver 5, The outlet of the improver 5 is connected to the inlet of the homogenizer 6, and the outlet of the homogenizer 6 is connected to the inlet of the granulator 7; the conditioner 2 is connected with a steam adding device 3, which can Saturated steam is added into the conditioner 2. On the one hand, water is added to the material, and on the other hand, the material can be fully matured. The conditioner 4 can be provided with one layer, two layers, three layers, or even more laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com