Multi-polar resolver

A resolver and rotor technology, applied in the direction of transformers, inductors, magnetic circuit rotating parts, etc., can solve the problems of complex structure and inapplicability of resolver, and achieve the effects of simple structure, reduced production cost and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

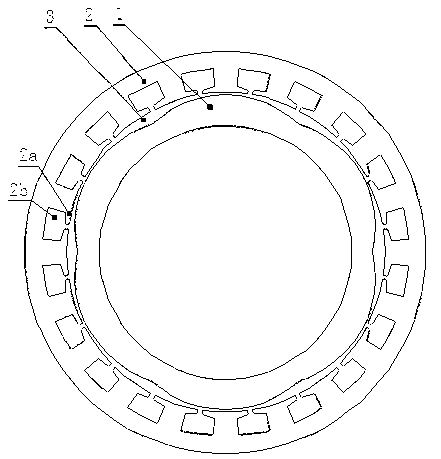

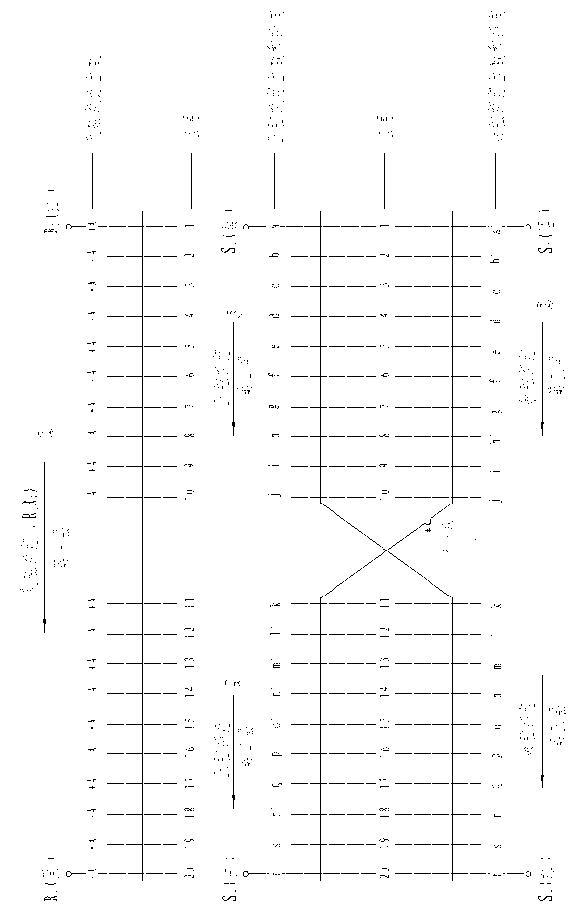

[0027] like figure 1 and figure 2 As shown, the multi-stage rotary transformer of the present invention includes a rotor 1 , a stator 2 , an excitation winding 4 , a sine winding 5 , and a cosine winding 6 . Both the rotor 1 and the stator 2 are formed by laminating multiple silicon steel sheets with high magnetic permeability. An air gap 3 is uniformly provided between the inner circular surface of the stator 2 and the outer circular surface of the rotor 1 . The outer circular surface of the rotor 1 is evenly provided with P wave crests and wave troughs. The wave crests and the wave troughs are smoothly connected to each other to form the wavy outer circular surface of the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com