Selecting method of resistance reducing surface film for pipeline transporting soft clay and viscoplastic material

A viscoplastic material, pipeline transportation technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. Achieve the effect of reducing pipe wear, small resistance along the way, and reducing wall friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Surface film selection test was carried out on soft clay with flat test panel.

[0032] The physical and mechanical indicators of soil samples: silty clay, water content 49.3%, soil particle specific gravity 2.73, void ratio 1.38, liquid limit 40.6%, plastic limit 20.1%, clay content 45%, permeability coefficient 9.69×10 -7 cm / s, compression coefficient 0.82MPa -1 , Consolidation coefficient 2.57×10 -3 cm 2 / s, compression modulus 2.5MPa, fast shear cohesion 11.7kPa, fast shear internal friction angle 7 degrees, solid fast cohesion 9.0kPa, solid fast internal friction angle 19 degrees.

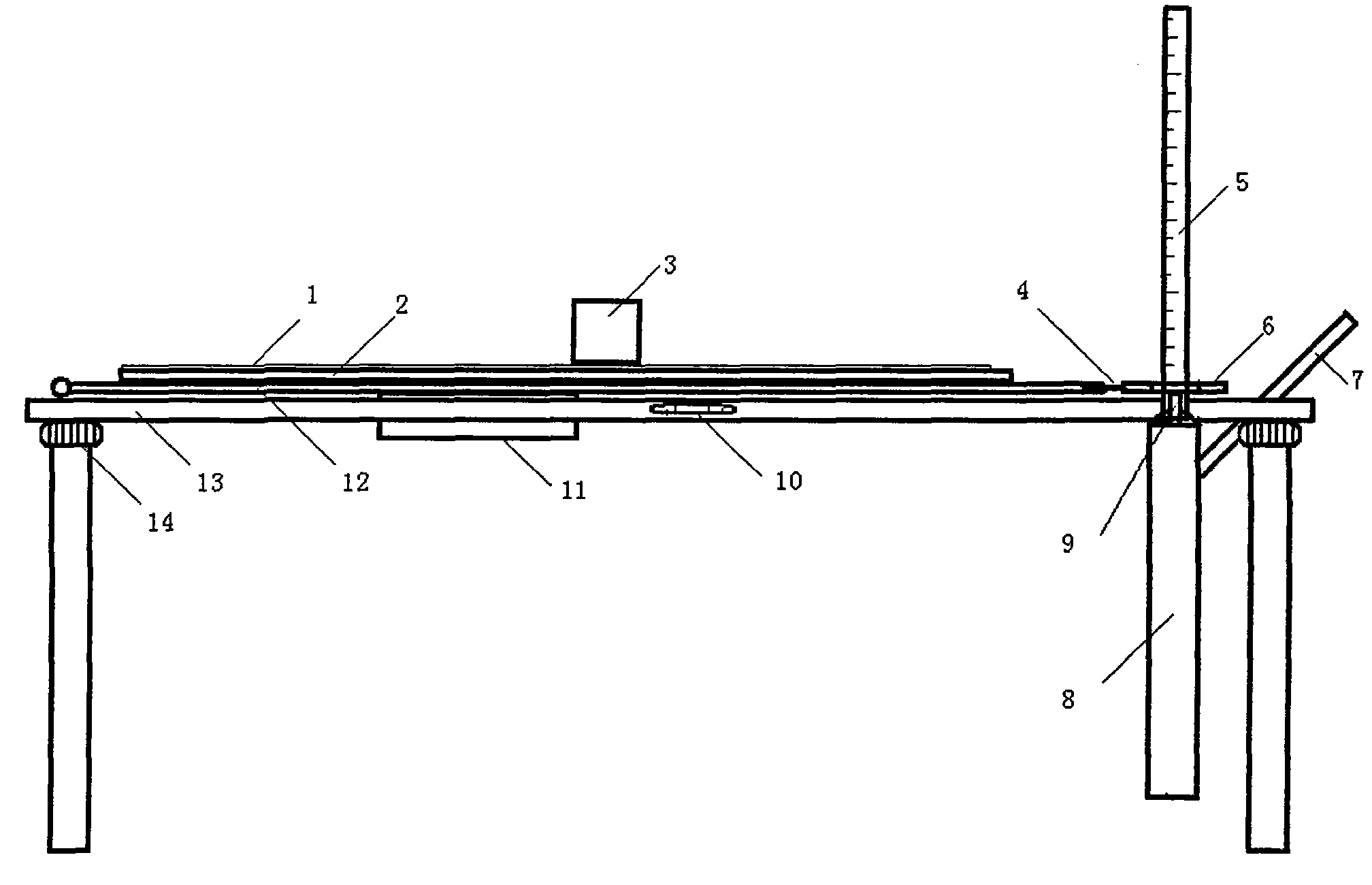

[0033] Such as figure 1 As shown, the surface film selection tester includes: a moving plate (12) and an adjustment system arranged on the test bench, a lifting device connected to one end of the moving plate (12), the lifting device adopts a hydraulic push rod (9) method, and the top plate (6 ) is connected with moving plate (12) by hinge (4). A vibrator (11) with adjust...

Embodiment 2

[0036] Example 2 Surface film selection test of soft clay with curved panel.

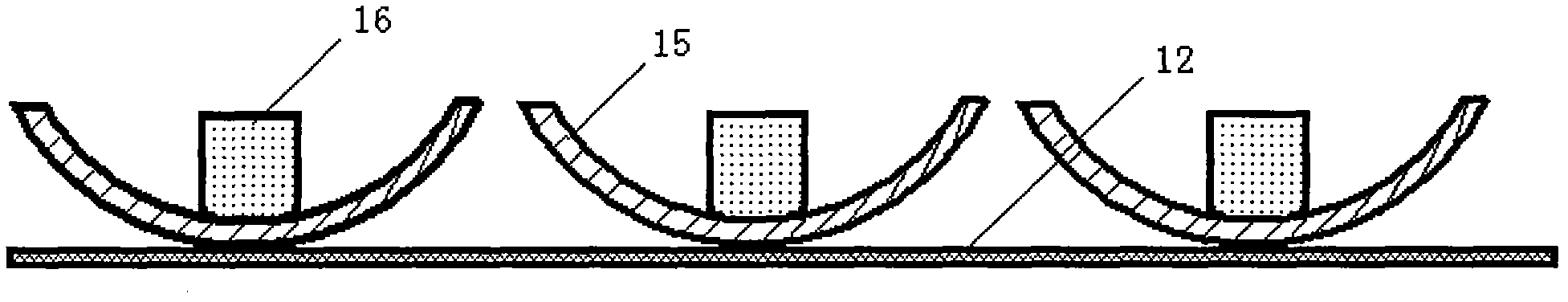

[0037] Such as image 3 Shown, 3 curved panels (15) are fixed on the moving plate (12), and its curvature is the same as that of the delivery pipeline, and is made of the same material as the delivery pipeline inner wall and treated with the same surface treatment. Spray three different surface film liquids on each curved panel (15) to form a surface film layer (1), and then gently place three identical circular test pieces (16). The experimental method is the same as in Example 1. The experimental data obtained in this way are closer to the working conditions in actual transportation.

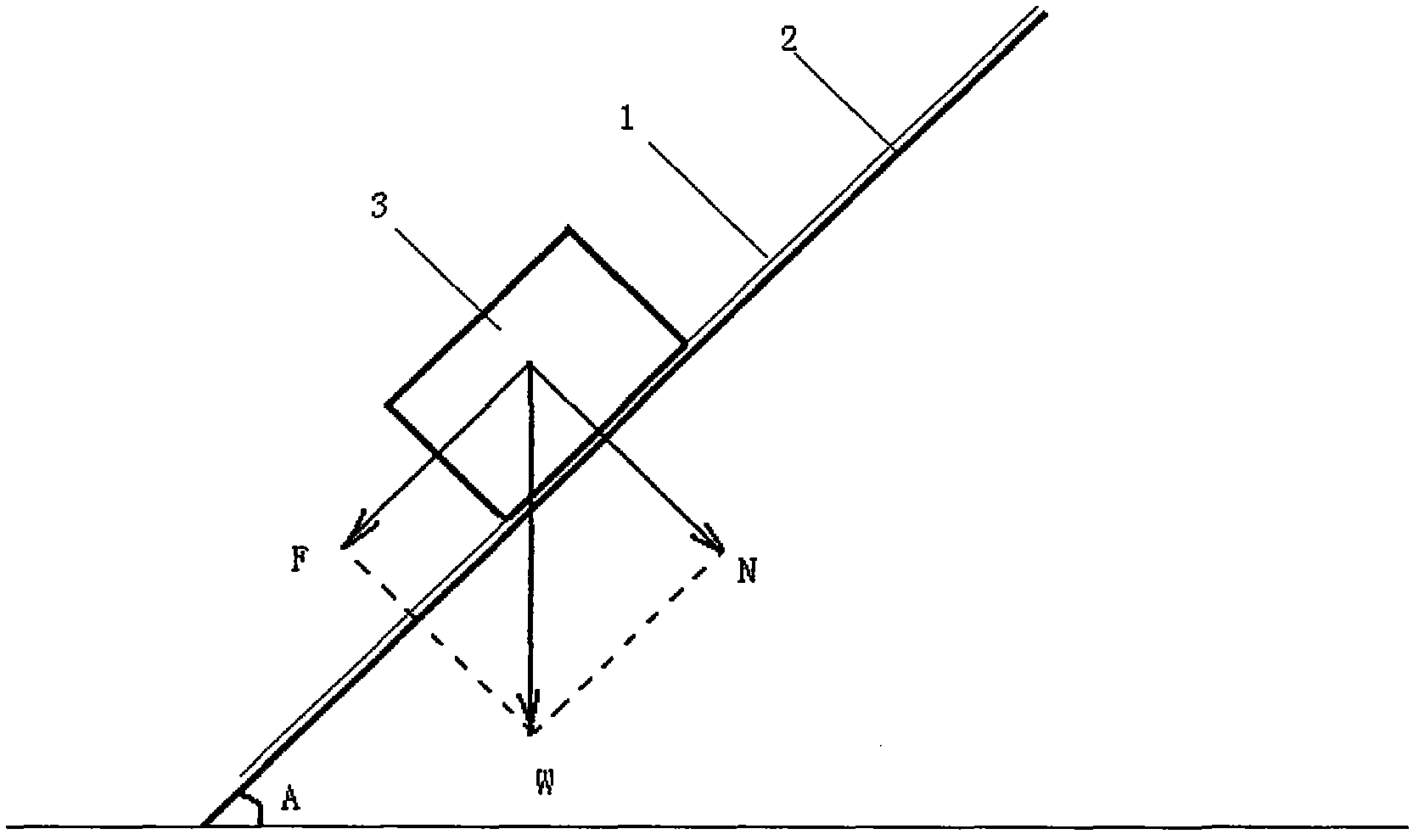

[0038] Such as figure 2 As shown, from the surface film selection tester, the weight (W) of the test piece, the contact area between the test piece and the test plate and the size of the moving plate (12) are known, not only can the comparison method be used to obtain the best surface film layer ( 1), and can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com