Mold for sewing front fly of clothing

A front door and clothing technology, applied in the direction of sewing tools, sewing equipment, sewing machine components, etc., can solve the problems of low work efficiency, complicated front door sewing process, time-consuming and labor-intensive, etc., to achieve reliable performance, consistent size, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

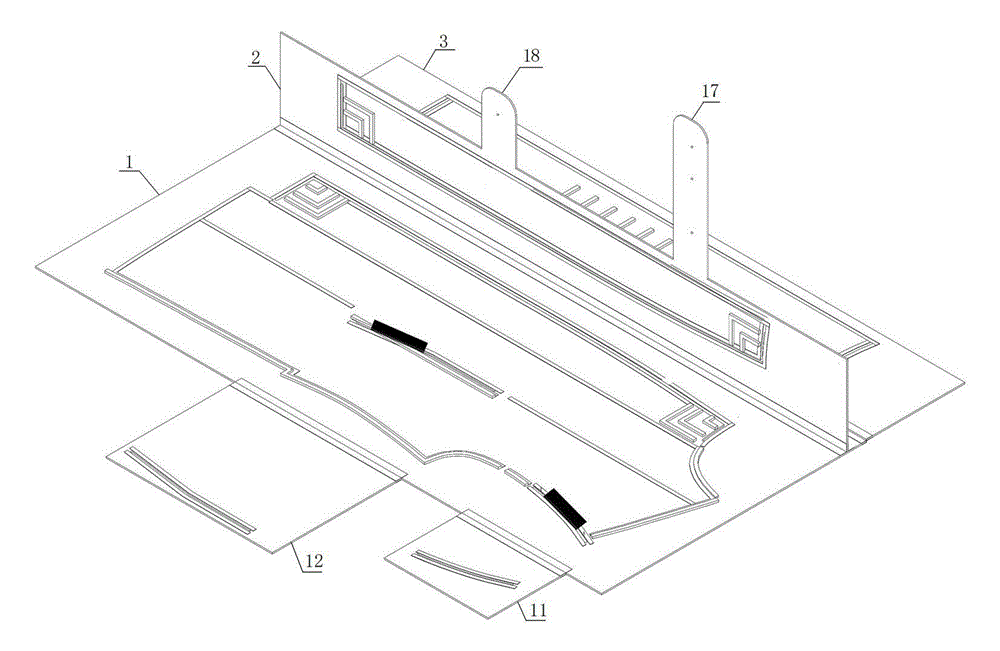

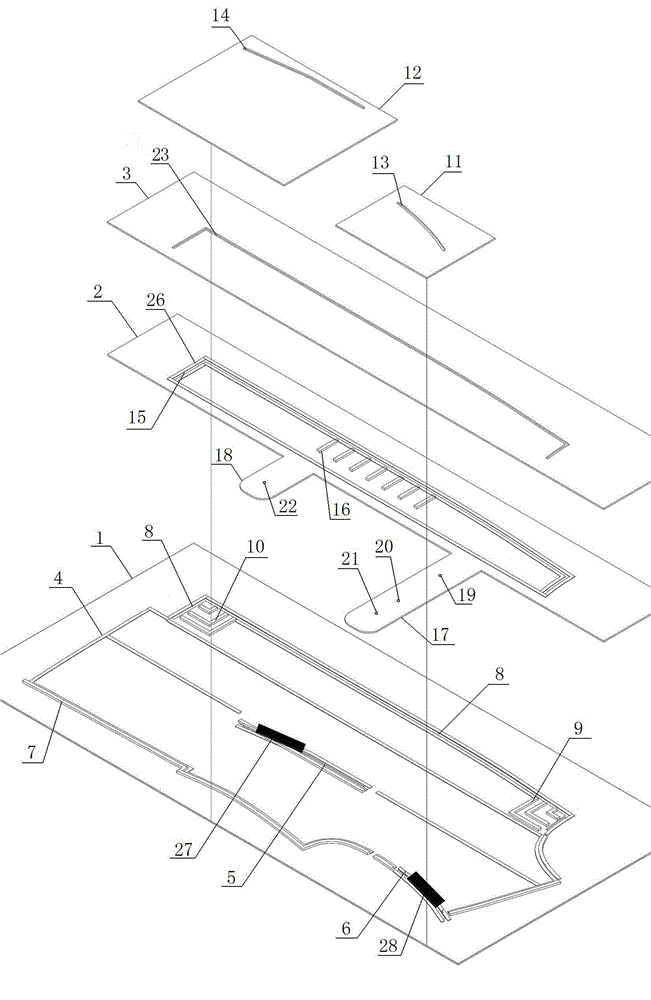

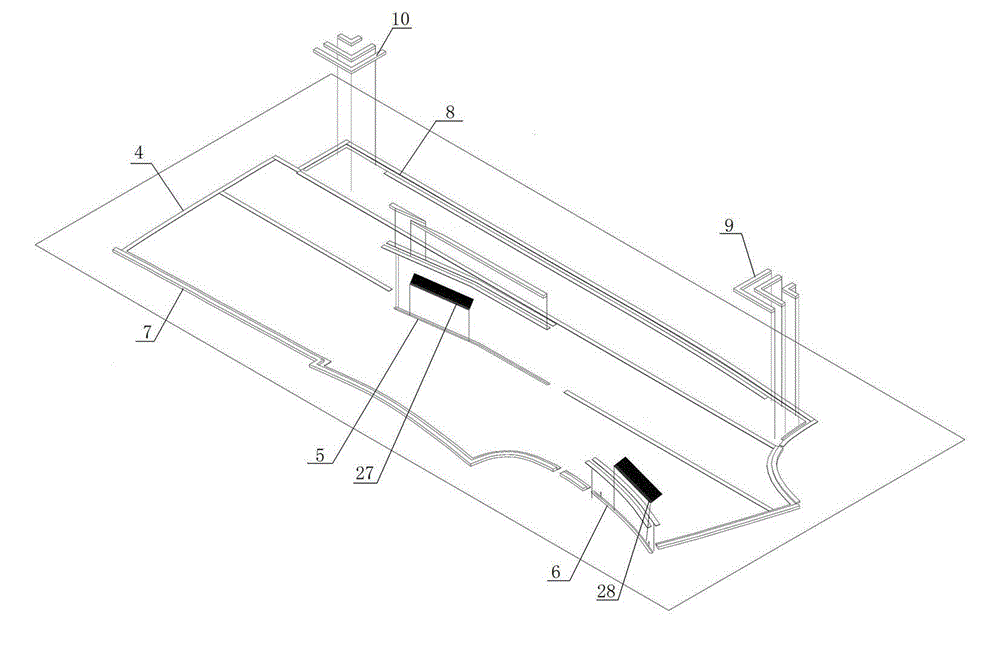

[0021] as attached Figure 1-8 As shown, the present invention includes a transparent rectangular bottom plate 1, a middle plate 2 and a cover plate 3, and the three opposite long sides on one side of the bottom plate 1, the middle plate 2, and the cover plate 3 are flexibly connected sequentially through adhesive plasters or tapes; The lower anti-slip slat 4 is arranged on the fastening surface of the bottom plate 1, and the lower anti-slip slat 4 is in the shape of the front door of the garment as a whole, and the front door connected by the collar edge, the hem edge and the front placket side is set at the seam welt of the front door. Front placket welt suture line through groove 8, set collar margin pad 9 at the inner collar of front placket welt suture line through slot 8, set hem margin pad at the hem of front placket welt suture line through slot 8 10. The margin block 9 of the collar is two elongated pads with two vertical tops on opposite sides. The corners of the mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com