Mixed feed for feeding yellow mealworms

A technology of mixed feed and Tenebrio molitor, applied in the field of agricultural product breeding, can solve problems such as insufficient research, and achieve the effects of improving the utilization rate and reducing the cost of breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

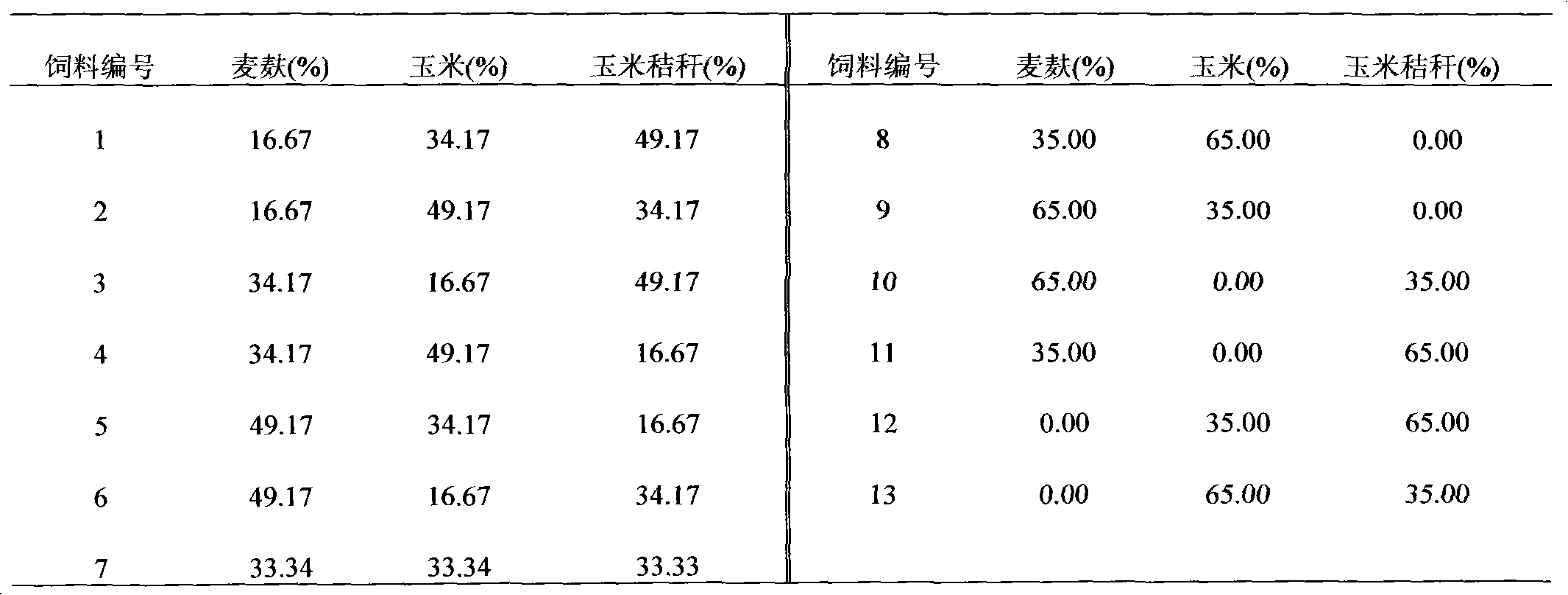

[0023] A mixed feed for feeding Tenebrio molitor, which is formed by mixing wheat bran, corn and corn stalks, wherein the corn stalks are crushed in advance and processed through fermentation, specifically, the corn stalks are pre-pulverized with an agricultural grinder. The straw is crushed and then fermented by alkali treatment.

[0024] Among them, the above-mentioned feed can ferment corn stalks and mix them with wheat bran and corn to feed Tenebrio molitor, which not only reduces the cost of breeding, but also converts cellulose into protein for human consumption. to great effect.

Embodiment 2

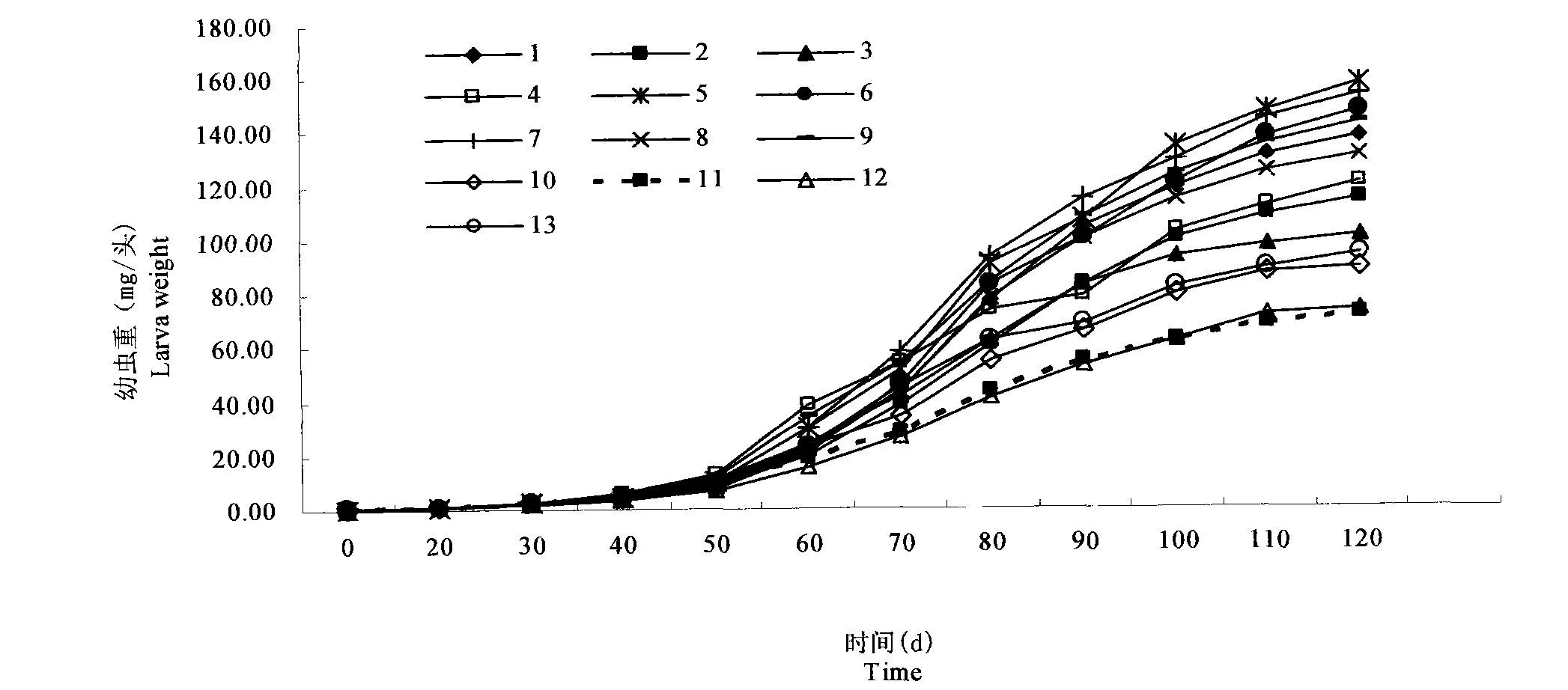

[0026] A mixed feed for raising Tenebrio molitor, which is formed by mixing wheat bran, corn and corn stalks, wherein the corn stalks are crushed in advance and subjected to fermentation treatment, wherein green fodder is added to the mixed feed, and the green fodder The proportion of the total feed is 5% (weight).

[0027] Wherein, the green feed selects non-irritating green vegetable leaves.

[0028] In this embodiment, green fodder is added to the feed, thereby accelerating the weight growth of Tenebrio molitor larvae, making the growth rate turning point appear earlier, shortening the growth cycle, saving feed and reducing breeding costs in production practice.

Embodiment 3

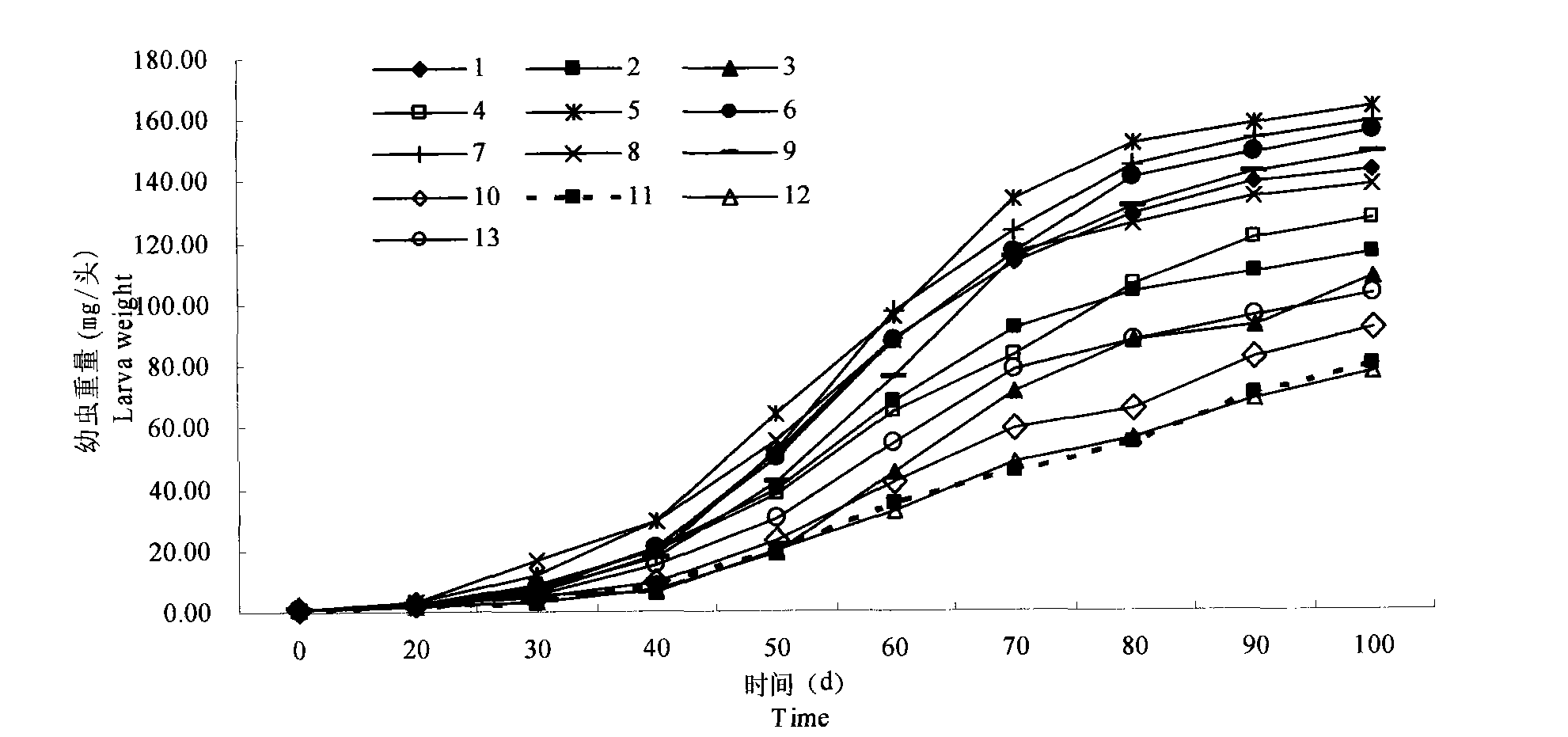

[0030] A mixed feed for feeding Tenebrio molitor, which is formed by mixing wheat bran, corn and corn stalks, wherein the corn stalks are crushed in advance and processed through fermentation, wherein the ratio of the wheat bran, corn and corn stalks is: 49.17%, 34.17% and 16.67% by weight.

[0031] Wherein, in a more preferred solution, green fodder is added to the mixed feed, and the ratio of the green fodder to the total feed is 5% (by weight).

[0032] In the present embodiment, the mixed feed has the optimal technical advantage of accelerating the weight growth of Tenebrio molitor larvae; and, after adding green feed, the turning point of growth rate can be made to appear early on the basis of the above, shortening the growth cycle, and improving the growth rate in production. In practice, feed can be saved and the cost of breeding can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com