Thermal plasma treatment device and method for low and medium level radioactive solid waste

A radioactive waste and thermal plasma technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of unfavorable radionuclide capture and control, inability to capture and solidify radionuclide heavy metals, radionuclide diffusion, etc., to achieve The effect of minimizing and stabilizing processing, safe and reliable processing, and reducing storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

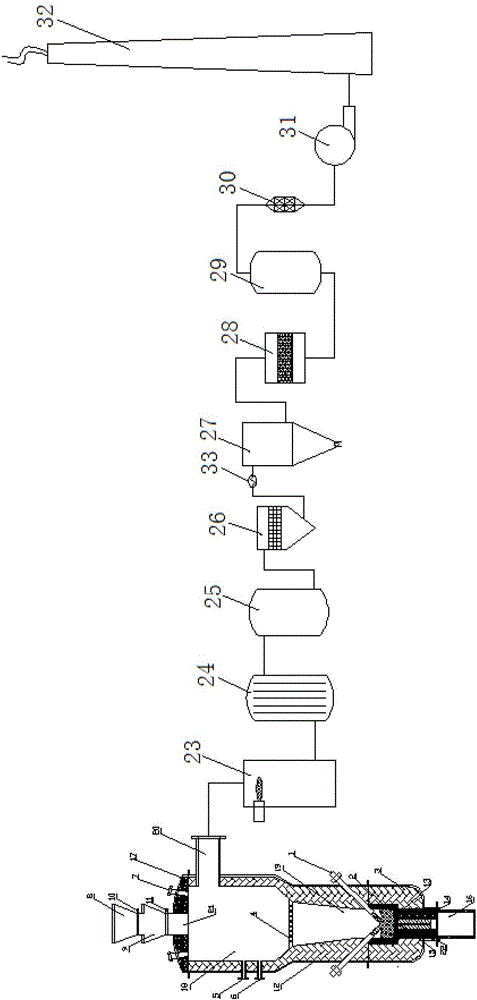

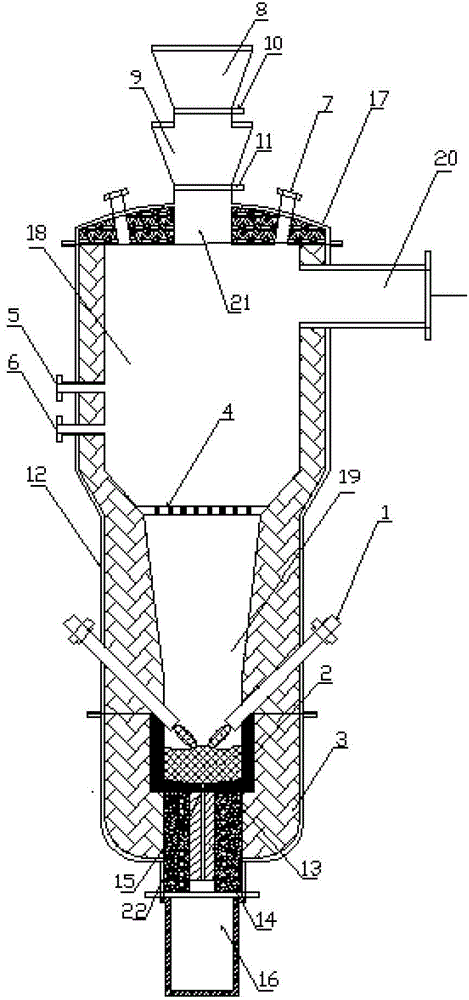

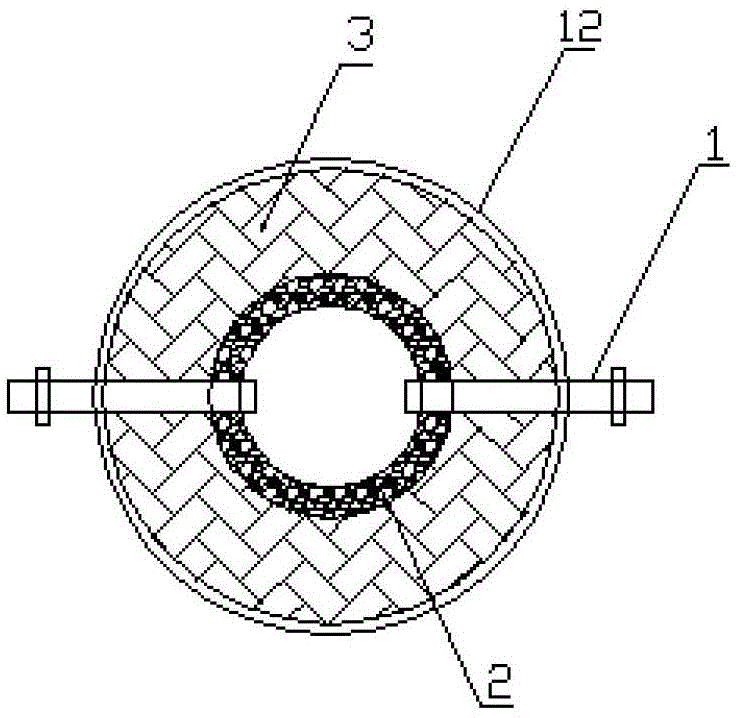

[0028] see figure 1 , 2 3. A device for thermal plasma treatment of low and medium level radioactive solid waste includes a plasma melter-gasifier, the furnace body includes a furnace body 12 and a furnace cover 17 that are interlocked, and the lower part of the furnace body 11 is provided with There is a molten pool crucible 2, the furnace grate 4 set in the furnace divides the furnace into two parts, the upper gasification zone 18 and the lower melting zone 19, and the lower side wall of the furnace body is provided with a plurality of channels extending to the upper end of the molten pool crucible 2. Holes, 2-4 DC plasma torches 1 can be installed as required, and are connected to the plasma discharge power supply through cables. The plasma torch working gas and cooling system are connected to the working gas preparation supply device and cooling water supply device through pipelines; the furnace The cover 17 is provided with a plurality of through holes, and the central t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com