Determining method for polydimethylsiloxane in edible oil and meat products

A technology of dimethylsiloxane and its determination method is applied in the field of analytical chemistry to achieve the effects of strong selectivity, low pollution and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

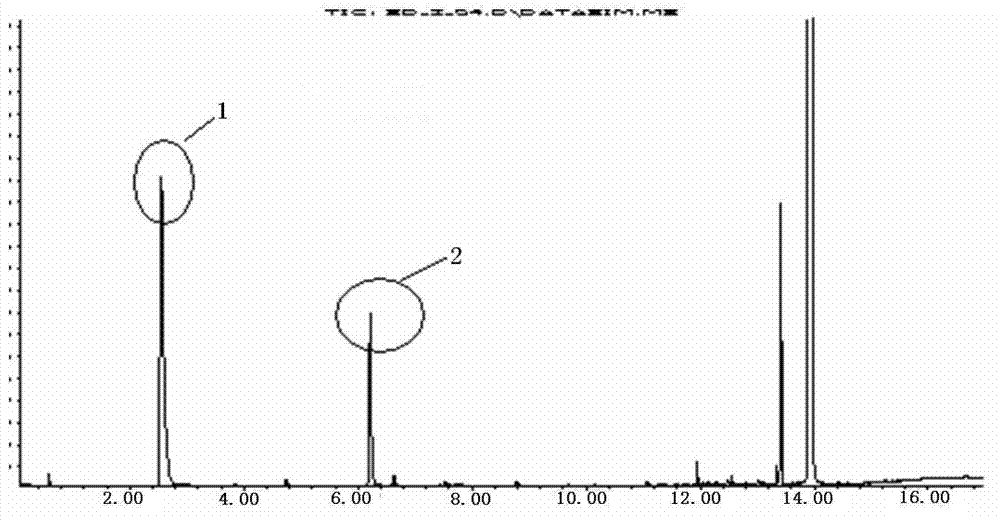

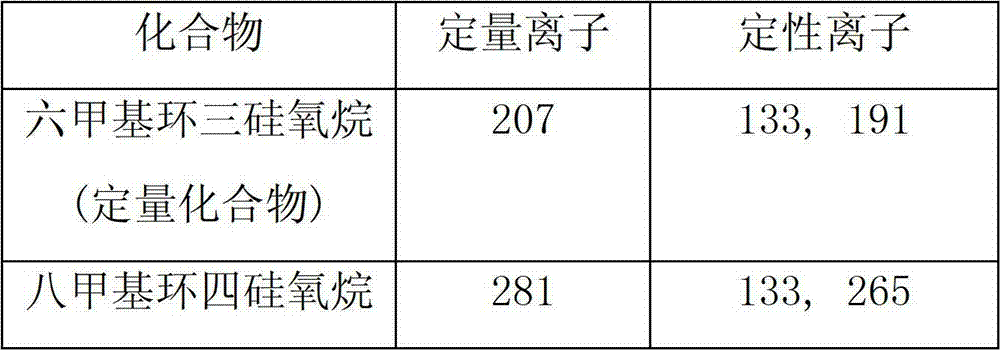

Image

Examples

Embodiment 1

[0024] Embodiment one, the mensuration of polydimethylsiloxane in edible oil:

[0025] 1. Preparation of sample solution

[0026] 1) Sampling: Accurately weigh 1.0g of edible oil sample into a 10mL glass centrifuge tube, the weight of the edible oil sample is accurate to 0.01g;

[0027] 2) Methyl esterification: Add 1mL of 2M methanolic potassium hydroxide solution to the edible oil sample, vortex and mix for 1min, then add 1mL of water to obtain a mixed solution;

[0028] 3) Extraction and separation: Add 2 mL of n-hexane to the mixed solution, vortex and mix for 3 minutes, transfer the n-hexane solution to a 10 mL centrifuge tube to obtain the extract, repeat the extraction once, and combine the two extracts;

[0029] 4) Concentration: Concentrate the combined extracts to 2 mL by nitrogen blowing at 45 °C, which is the sample liquid.

[0030] 2. Set the instrument parameters

[0031] 1) Cracker conditions

[0032] Interface temperature: 310°C

[0033] Cracking temperatu...

Embodiment 2

[0057] Embodiment two, the mensuration of polydimethylsiloxane in the meat product:

[0058] 1. Preparation of sample solution

[0059] 1) Sampling: Accurately weigh 1.0g of meat product sample, the weight of the meat product sample is accurate to 0.01g, wrap the meat product sample with filter paper, extract the fat in the meat product sample through ether Soxhlet, extract with ether for 7 hours, and reflux 6-8 times / h, rotary steamed at 180bar, 40℃ to 4-6mL, then concentrated to 0.5mL by nitrogen blowing;

[0060] 2) Methyl esterification: Add 1mL of 2M methanolic potassium hydroxide solution to the edible oil sample, vortex and mix for 1min, then add 1mL of water to obtain a mixed solution;

[0061] 3) Extraction and separation: Add 2 mL of n-hexane to the mixed solution, vortex and mix for 3 minutes, transfer the n-hexane solution to a 10 mL centrifuge tube to obtain the extract, repeat the extraction once, and combine the two extracts;

[0062] 4) Concentration: Concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com