Planetary wheel loading device for ground test equipment of rotating wing plate for aircraft

A loading device and ground test technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as large redundant resistance moment, increased strength and stiffness, and increased geometric dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

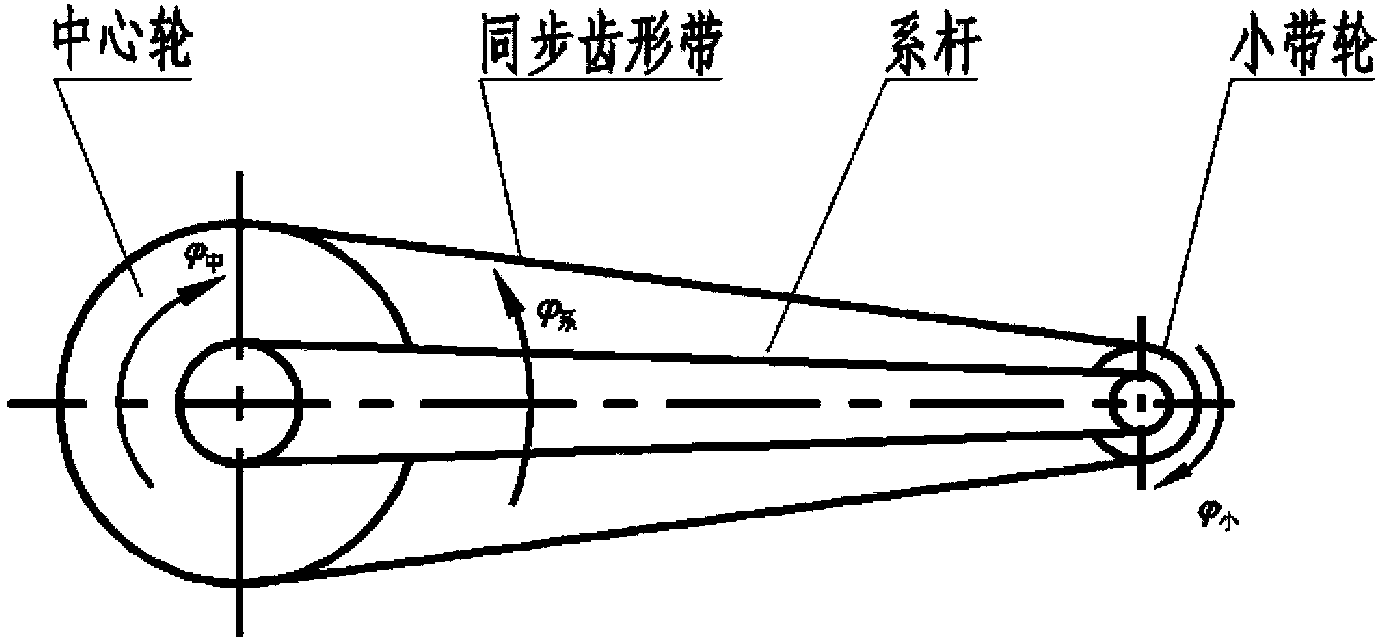

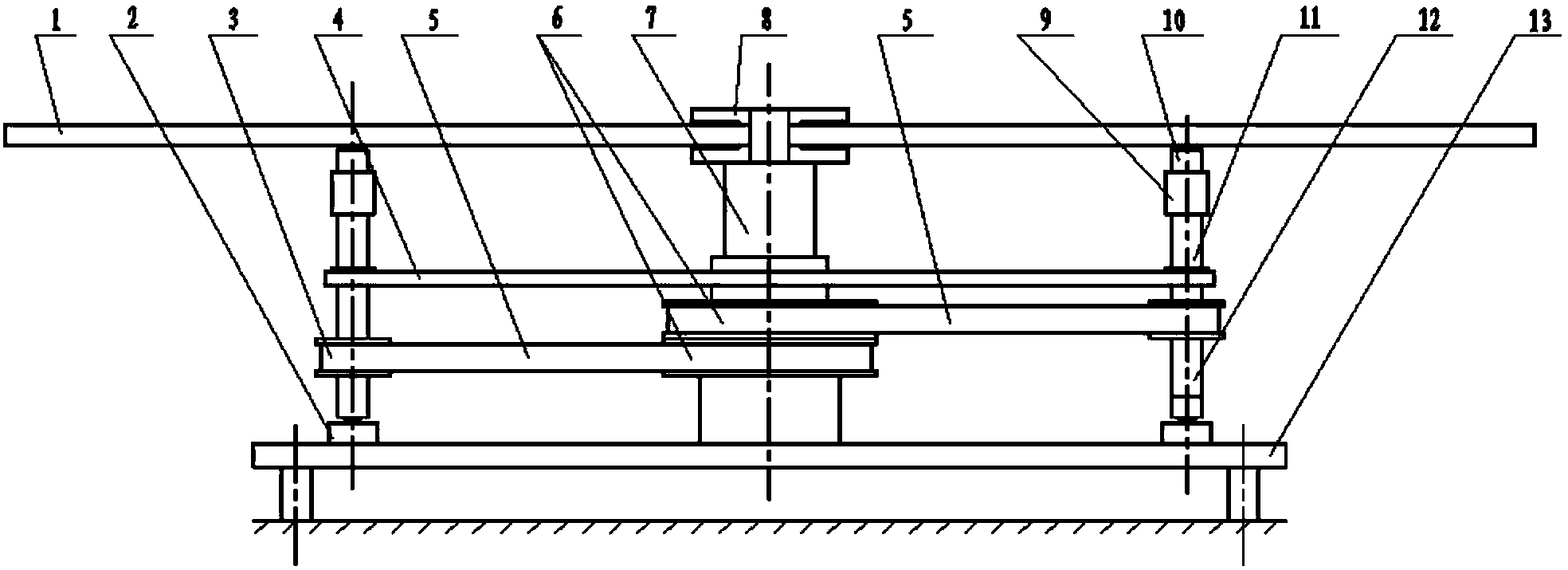

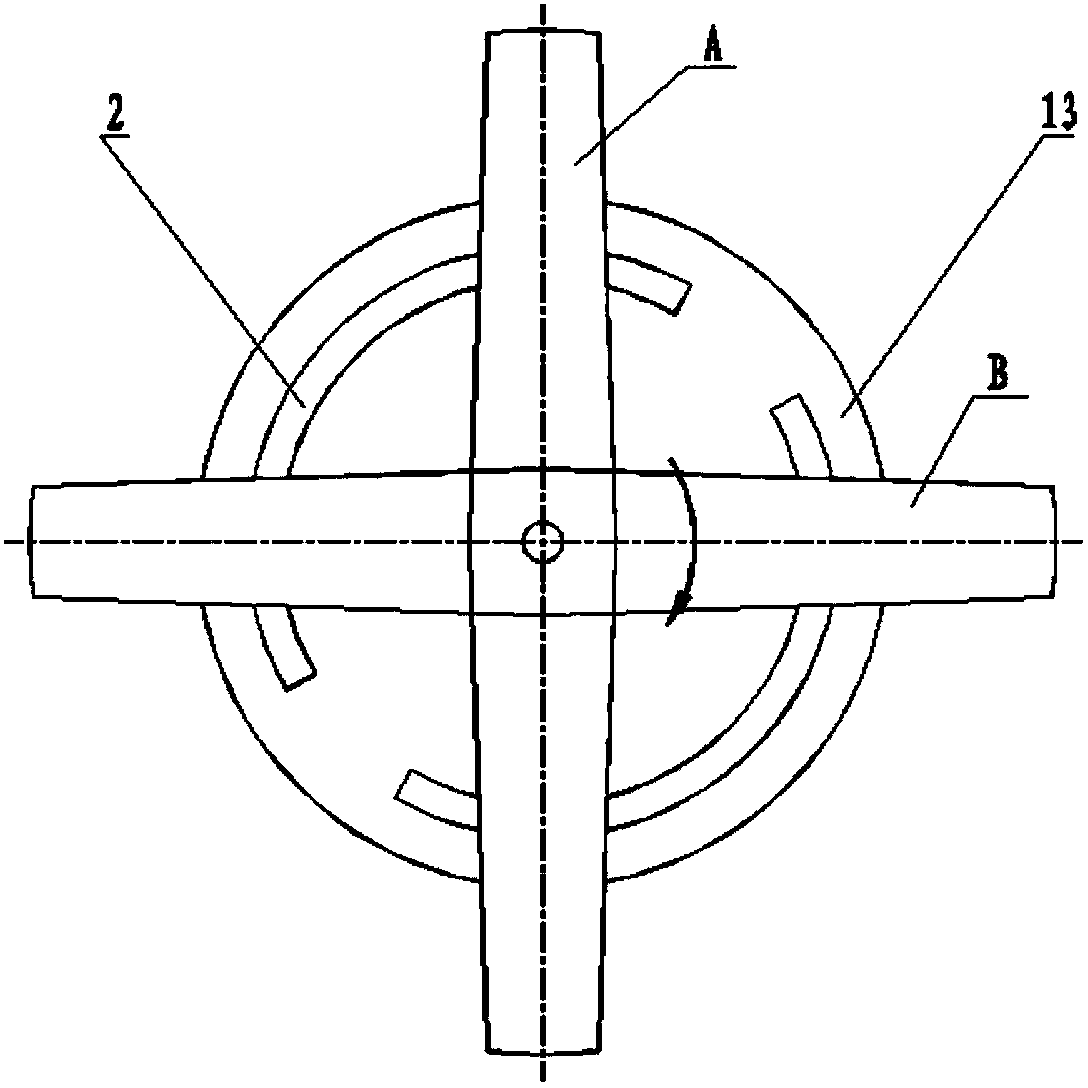

[0021] The present invention comprises a base, a central column and a loading device. The base is vertically provided with a central column, and two wing plates are installed on the top of the central column through a wing plate bracket. The loading device is composed of a ball screw nut and is fixed on a tie rod that can rotate around the column. The lower end of the screw moves along the circular guide rail on the base, and the upper end contacts the lower wing surface of the wing plate through a pressure sensor. As the center of the circle, the two loading devices are symmetrical to the central column. The servo motor drives the tie rod to drive the loading mechanism to rotate synchronously with the wing plate. The center column is coaxially surrounded by a center wheel. The belt drives the small pulley coaxially connected with the lead screw to rotate, and the lead screw drives the nut to move in the axial direction, applying a simulated aerodynamic load to the wing plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com