Special screwed joint for gas injection and production of underground gas storage

A special threaded and external threaded joint technology, applied in the direction of threaded connections, pipes/pipe joints/fittings, passing elements, etc., can solve the problem of poor sealing performance, easy slippage of round threads, and inability to meet the requirements of gas injection and production in underground gas storage. Air requirements and other issues, to achieve good sealing ability, enhance safety and reliability, the effect of small taper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

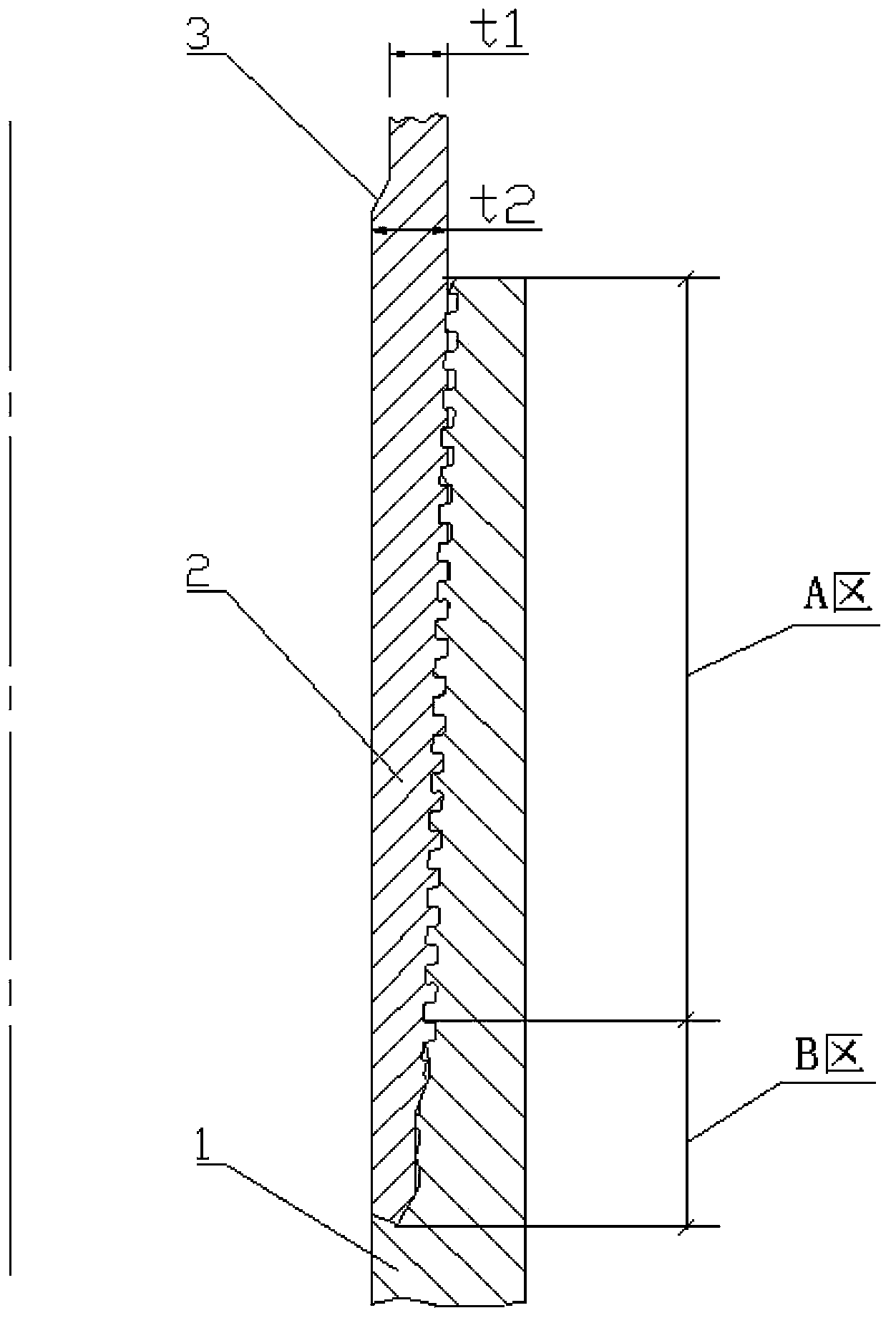

[0064] Such as figure 1 As shown, the embodiment of the present invention provides a special threaded joint for gas injection and gas production in an underground gas storage. The special threaded joint includes an external threaded joint 2 and an internal threaded joint 1 assembled together. The special threaded joint The assembly part is divided into a thread engagement section A area and a main sealing section B area, and the thread engagement section A area is connected to the main sealing section B area;

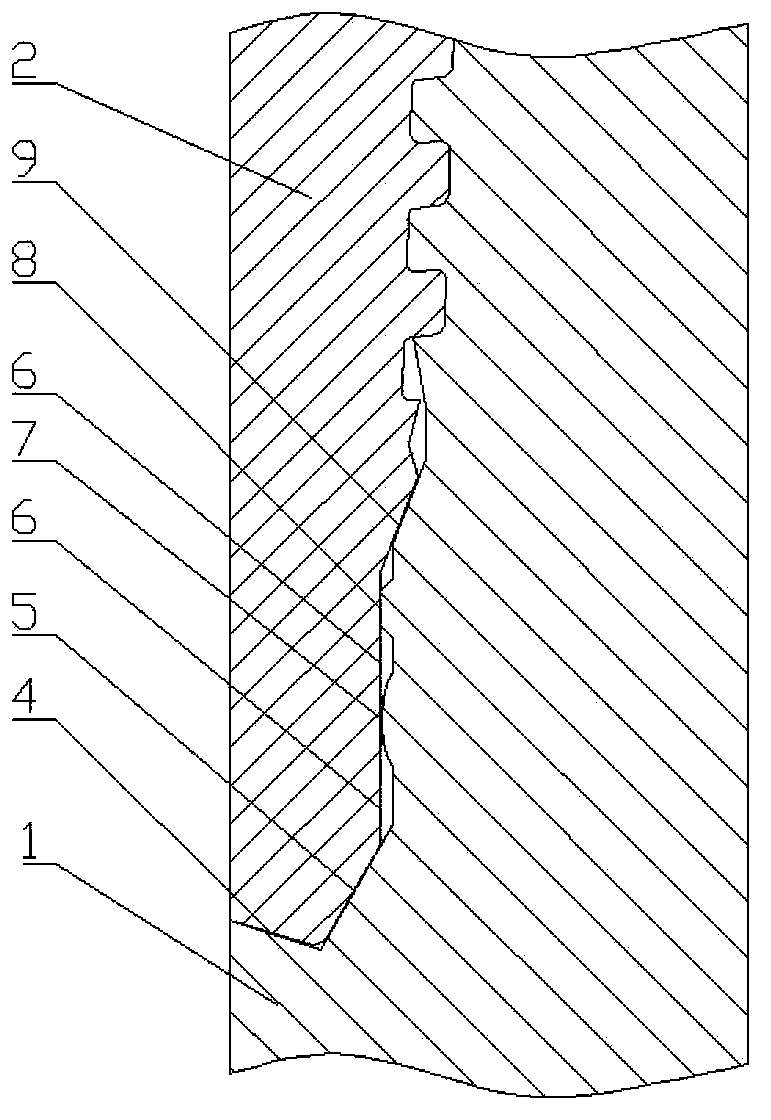

[0065] The threads in the thread engagement section A of the externally threaded joint 2 and the internally threaded joint 1 are both hook-shaped deep-toothed threads;

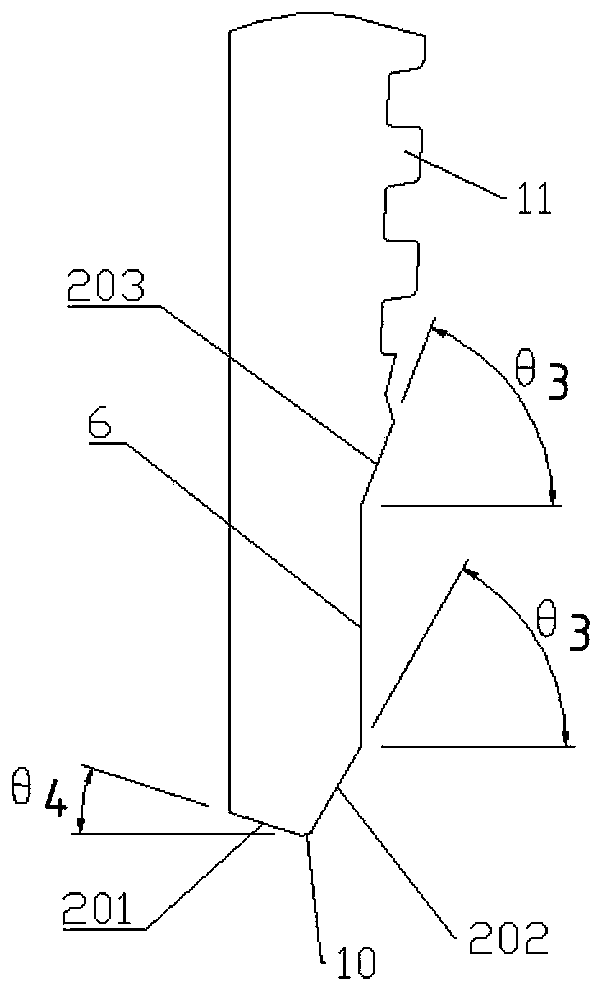

[0066] Such as figure 2 As shown, the area B of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com