On-line automatic turning mechanism for tire belted layer

A technology of automatic inversion and belt layer, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of low inversion efficiency, high labor intensity, production impact, etc., to improve the degree of automation and production efficiency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

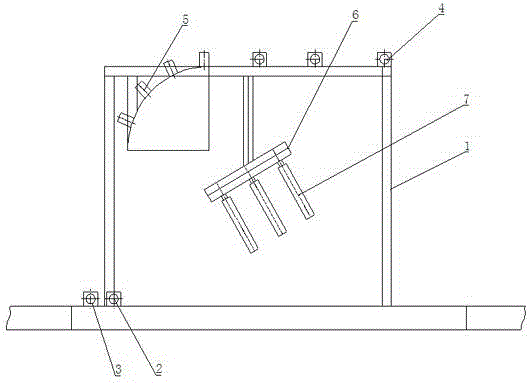

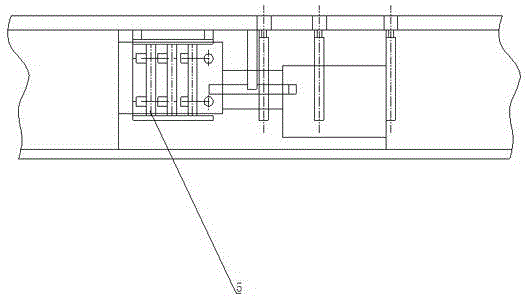

[0009] Such as figure 1 , 2 As shown, it includes a frame 1, a rear steering guide roller 2, a front steering guide roller A3, a front steering guide roller B4, a front guide roller group 5, an overturn bracket 6 and an overturn guide roller 7.

[0010] The above-mentioned overturning station is set between the front conveyor belt and the rear stage, the front conveyor belt is located in the belt layer hemming section, and the rear conveyor belt is located in the belt lamination edge pressing section.

[0011] The overturning station includes a frame 1, on which the lower guide roller group, the middle overturning roller group and the upper layer guide roller group are installed sequentially from bottom to top.

[0012] The lower guide roller group includes the rear steering guide roller 2 and the front steering guide roller A3. The rear steering guide roller 2 and the front steering roller A3 are all installed on the front end of the lower layer of the frame 1 near the rear ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap