Automatic box-packing equipment and process for industrial seismic explosive columns

A technology of seismic source powder column and automatic boxing, which is applied in the direction of packaging, etc., can solve the problems of low production efficiency, high labor intensity, casualties, etc., and achieve the effect of reducing operators, reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings.

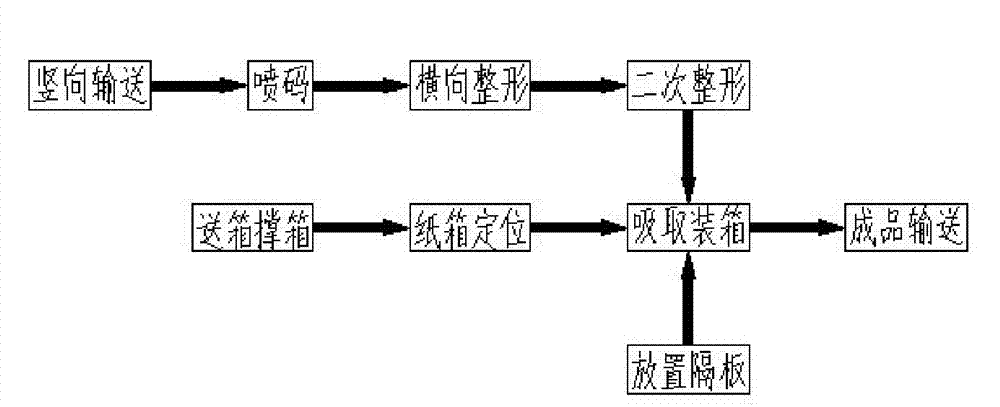

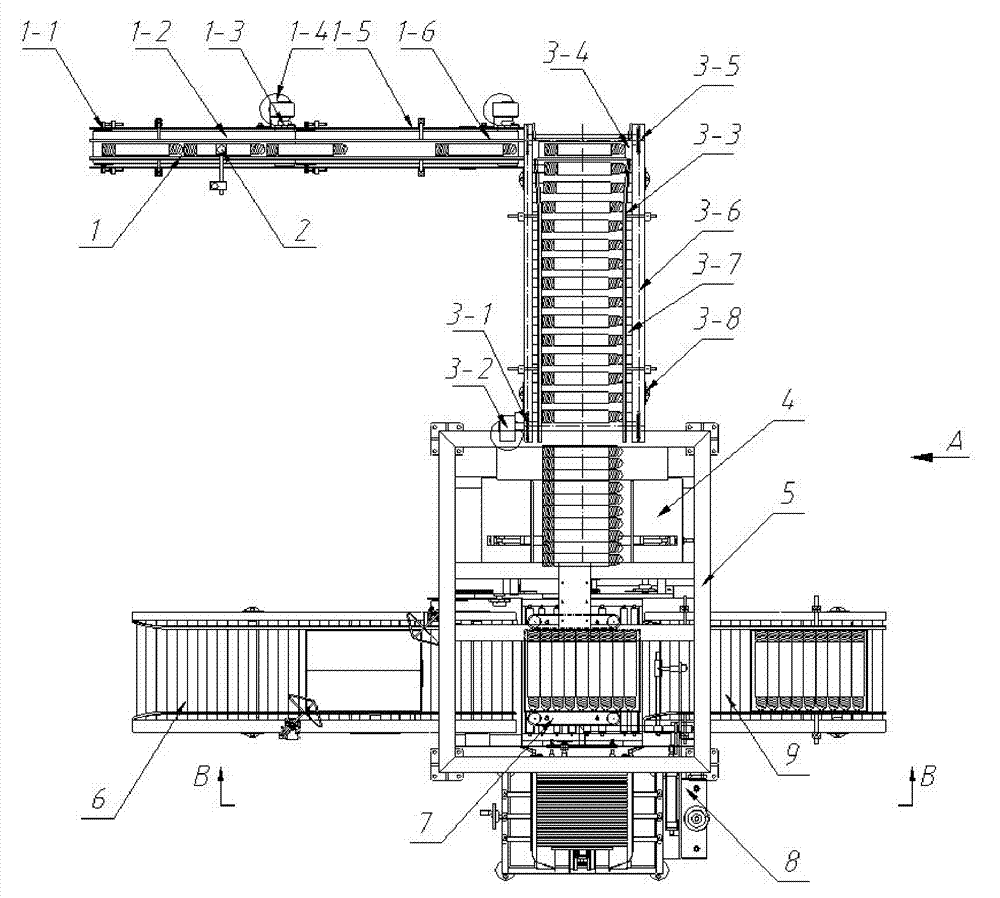

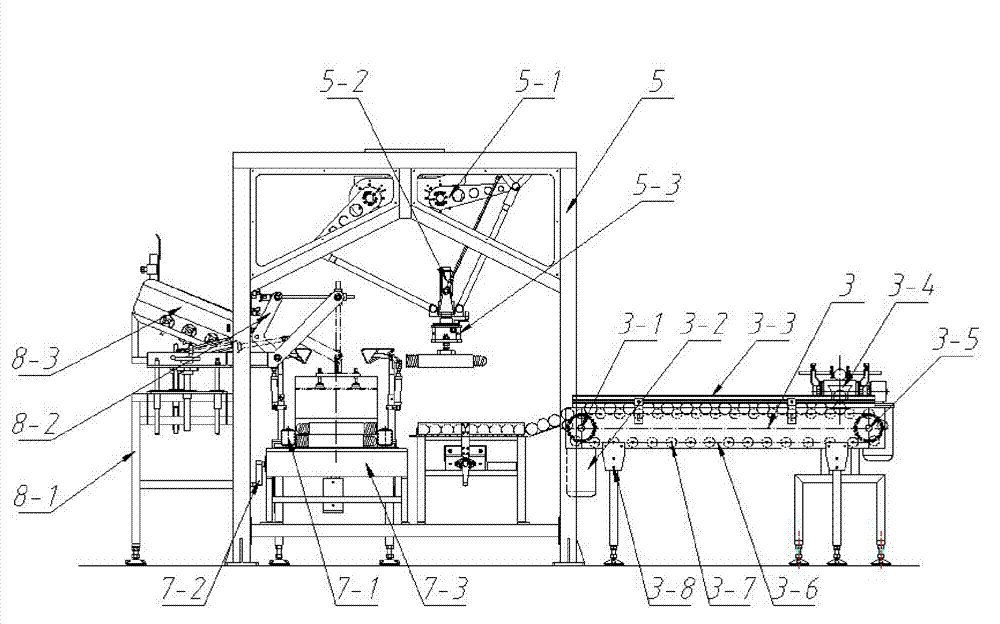

[0022] like figure 2 As shown, the automatic boxing equipment for industrial explosive seismic source grain provided by the present invention includes a belt feeding mechanism 1, a coding device 2, a grain shaping roller mechanism 3, a grain secondary shaping mechanism 4, a plane joint manipulator 5, Roller box feeding mechanism 6, carton positioning mechanism 7, partition placing mechanism 8, roller table output mechanism 9. The input end of the belt drug delivery mechanism 1 is connected to the front-end conveying mechanism, the output end of the belt drug delivery mechanism 1 is connected to the drug column shaping roller mechanism 3 at 90° vertically, and the coding device 2 is placed on the belt of the belt drug delivery mechanism 1. Above; the output end of the grain shaping roller mechanism 3 is connected to the grain secondary shaping mechanism 4; the plane joint m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com