Automobile crane and driving system thereof

A technology for truck cranes and drive systems, which is applied to vehicle components, circuits or fluid pipelines, control devices, etc., and can solve problems such as low efficiency, limited drive capacity, and difficulty in driving more than five axes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a driving system for a truck crane, which can meet the dual requirements of truck crane operation and transition, and adapt to the development trend of large-scale truck cranes. Another core of the present invention is to provide a truck crane including the above drive system.

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

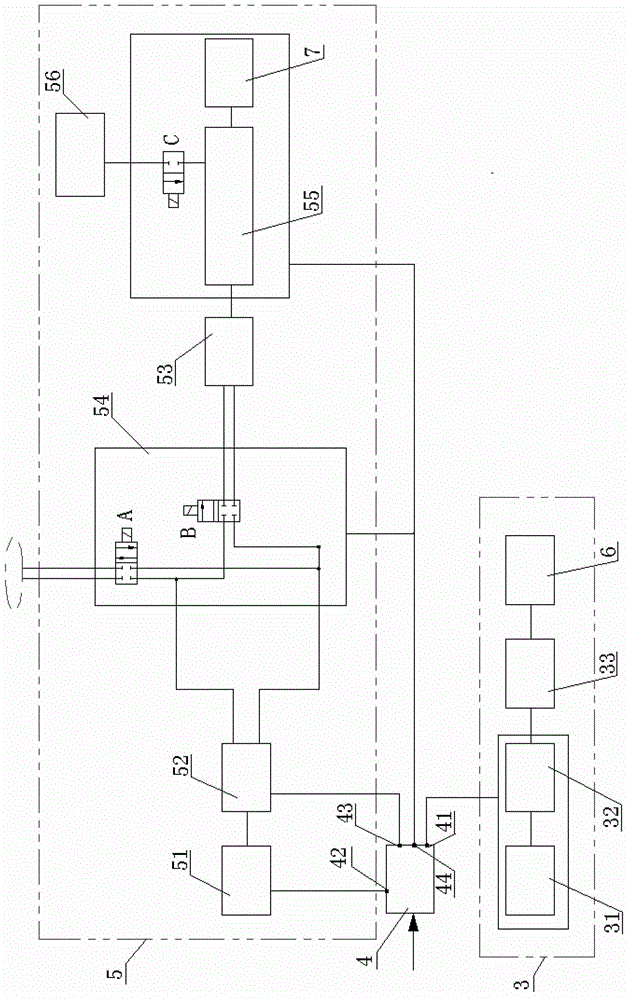

[0027] Please refer to image 3 , image 3 It is a structural connection schematic diagram of a specific embodiment of the drive system provided by the present invention.

[0028]The drive system provided by the present invention is used to drive a large-tonnage truck crane. The drive system not only includes a mechanical drive module 3 and a hydraulic drive module 5, but also includes a controller 4 f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap