Reciprocating regenerating type full-automatic roll curtain air filtering device

An air filter, fully automatic technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of less manual maintenance, reduce labor intensity, solve production shutdown, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

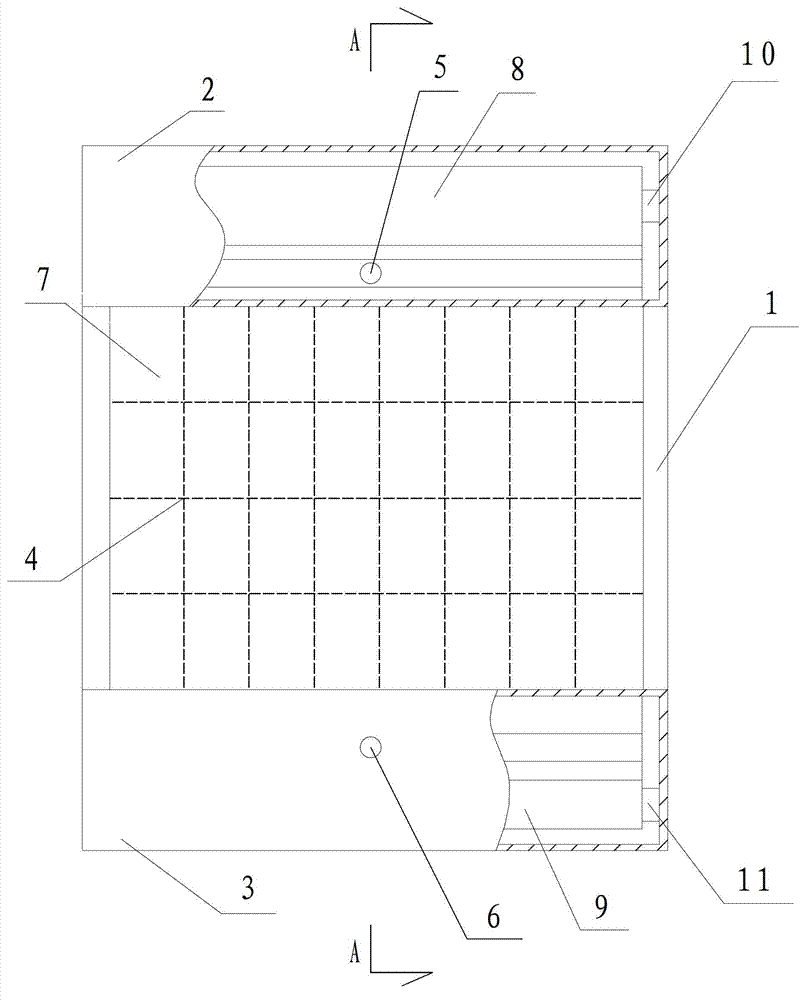

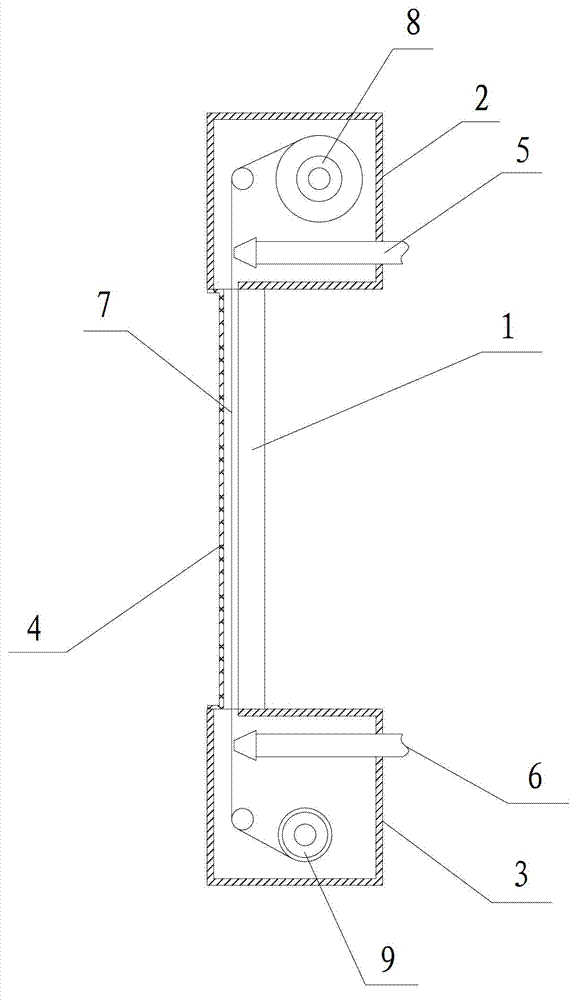

[0009] see figure 1 , 2 , the filter has a main body bracket (not shown in the figure), and an upper filter material box (2) and a lower filter material box (3) are respectively fixed at the upper and lower ends of the main body bracket. An upper filter material roll (8) and a lower filter material roll (9) are respectively arranged in the upper filter material box and the lower filter material box, and a roll of filter material ( 7), the filter material (7) is a regenerated filter material, and the regenerated filter material can be made of nylon material; there is a filter material back grill (4 ), a pair of filter spring sealing rods (1) are arranged on both sides of the front of the filter material spread between the upper and lower filter material rollers, and the filter backrest grid and filter material spring sealing pressure rods are fixed on the On the main body bracket; there is a row of electromagnetic springs in the material filter spring sealing pressure rod. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com