Chopping-type stalk returning-to-field machine

A straw and frame technology, applied in the field of straw returning machines, can solve the problems of nutrient loss, high operation cost, and large power consumption, and achieve the effects of good nutrition retention, low maintenance cost, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

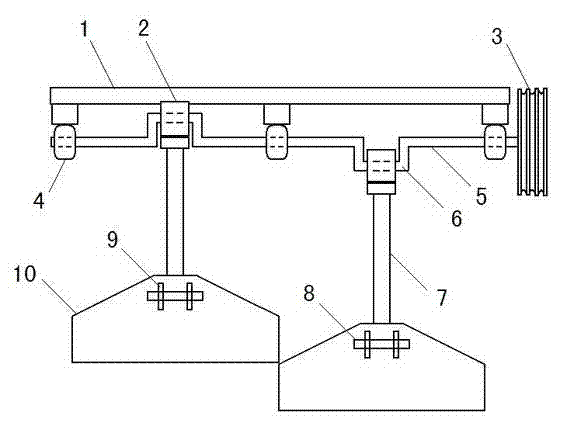

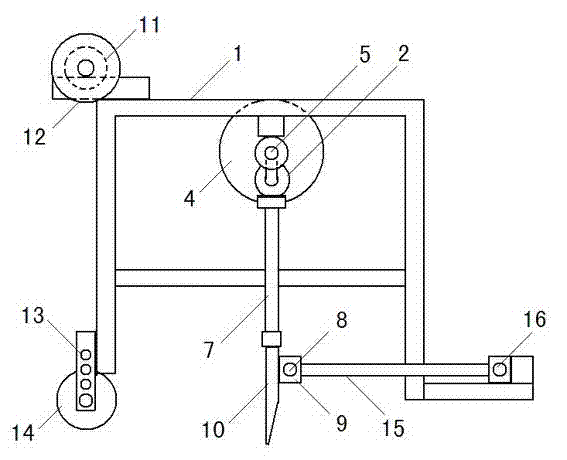

[0020] Such as figure 1 , 2 As shown, a cutting and chopping straw returning machine includes: the two ends and the middle part of the main shaft 5 are fixed on the frame 1 through bearings 4 (can be above or below the rod of the frame 1), and two The crankshaft 6 is inverted. The crankshaft 6 is connected to the cutter bar 7 and the cutter 10 underneath through the bushing 2. The cutter 10 is a flat plate with a trapezoidal structure with a small upper part and a large lower part. The bottom is thin or has a blade; A shaft plate 9 is provided at the rear of 10, the shaft plate 9 is connected to a tie rod 15 through a shaft 8, and the rear end of the tie rod 15 is connected to the lower part of the frame 1 through a shaft 16.

[0021] The front part of the frame 1 is connected to the suspension shaft and the lifting rod of the tractor through a connecting rod. Two roller frames 13 are also provided on the lower front part of the frame 1. The roller frame 13 is provided with horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com