Node heating method for ground potential treatment substation equipment

A technology of substation equipment and ground potential, applied in substation grounding layout, electrical components, switchgear, etc., can solve problems such as difficulty in effectively eliminating heating defects, inability to open the contact surface for processing, and restriction of processing effect, so as to achieve convenient installation and avoid The effect of direct contact and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A ground potential treatment method for heat generation of substation equipment nodes, the steps are as follows:

[0060] (1) The ground potential electrician first installs the rust remover paint spraying device for the ground potential operation and sprays the rust remover on the bolts at the hot spot. (2) Use the bolt removal tool for the ground potential work to disassemble the bolts at the hot spot. (3) The ground potential electrician uses an insulating operating rod to prop up the lead wire end, and then grinds the contact surface with the ground potential work grinding device. The job transports the gasket tool to restore the bolted connection and tighten it.

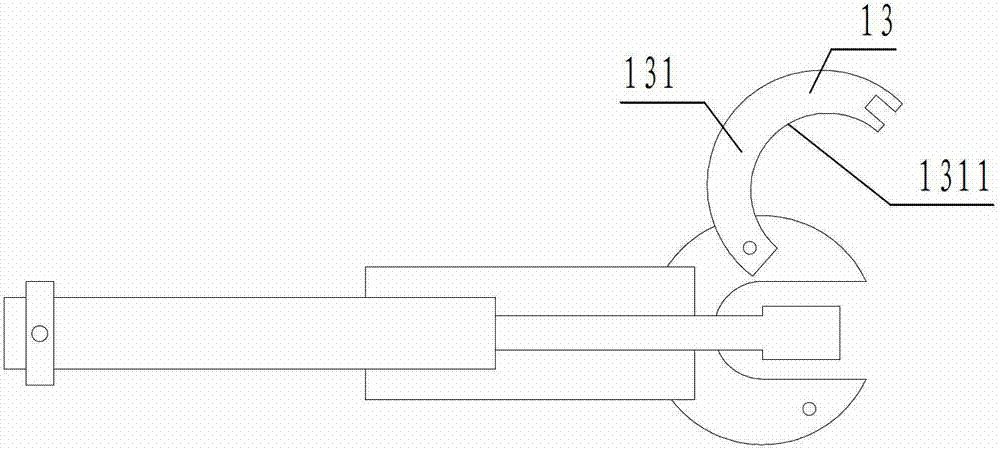

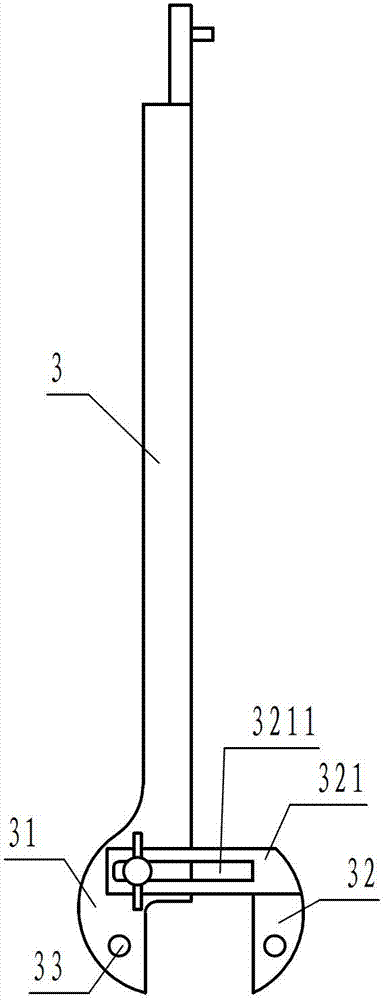

[0061] as described figure 1 , 2 The shown rust remover spraying device for ground potential operation is a clamp-like structure. The clamp-like structure includes two monomers 11 arranged crosswise and hinged together. The two monomers are divided into clamping ends and At the handle end, a pressing p...

Embodiment 2

[0067] This embodiment is basically the same as Embodiment 1, except that when using the ground potential working bolt dismounting tool to disassemble the heat point bolts, one ground potential electrician uses a stop wrench to prevent the bolts from rotating, and the other uses a tool to loosen the bolts, and Disassemble one by one. The ground potential treatment method for heat generation of substation equipment nodes further includes using ground potential work diversion wire clips to shunt the heat generation points.

[0068] The specific operation of shunting the heating point is as follows: (1) the ground potential electrician first hangs 2 pulleys and insulating transfer ropes above the heating point, (2) the ground potential electrician assembles the ground potential work diversion wire clip into the required (3) Hang the two ends of the two clamps of the ground potential work diversion wire clamp on the two transmission ropes respectively, and hang two control ropes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com