Steel rail ultrasonic on-line detection system and control method thereof

A detection system, ultrasonic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

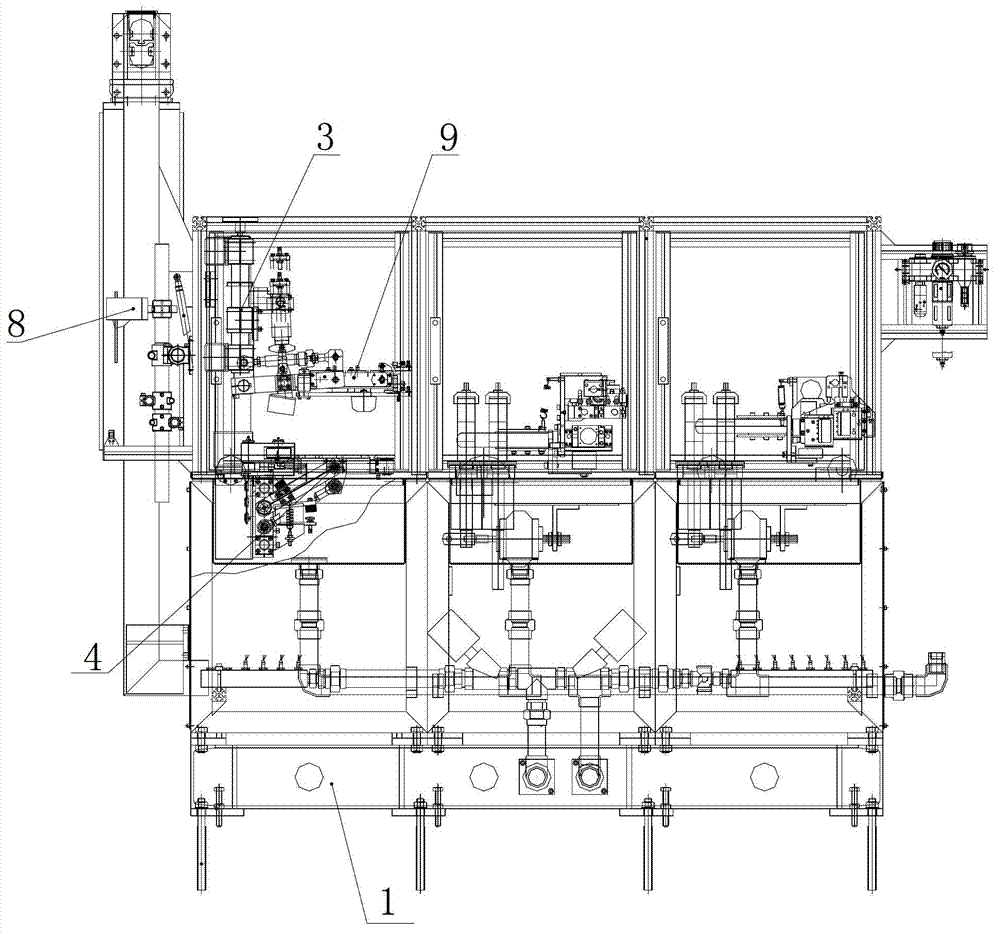

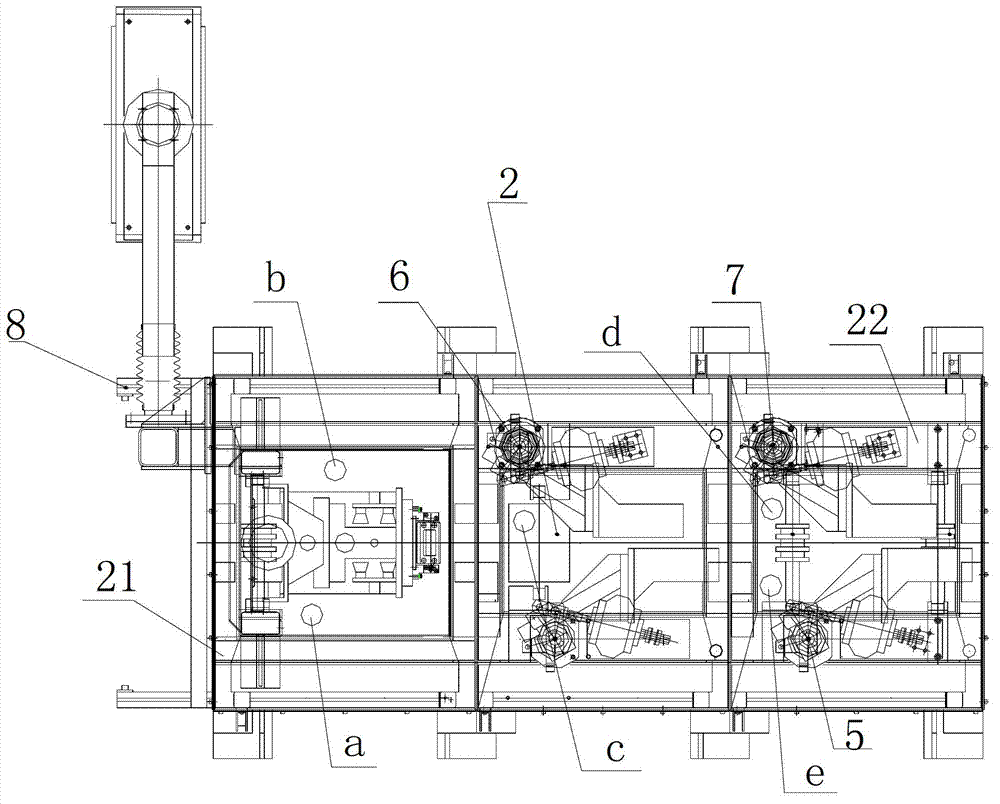

[0029] Such as figure 1 , figure 2 Shown: an ultrasonic online detection system for rails, the equipment includes a bracket 1, a roller table 2, a rail head tread landing gear 3, a rail bottom landing gear 4, a rail head right landing gear 5, a rail head left landing gear 6, Landing gear 7 on the left side of the rail waist, No. 1 through-beam photoelectric, No. 2 through-beam photoelectric, No. 3 through-beam photoelectric, No. 4 through-beam photoelectric, rail position detection device, controller and ultrasonic detector. The roller table 2 is located on the support 1, and the roller table 2 includes an inlet port 21 and an outlet port 22. When the rail is normally detected, it enters from the inlet port 21 and goes out from the outlet port 22. It is the opposite when pouring steel. For safety protection, a rail shape sensing device 8 for sensing the shape of the rail track is provided on the bracket 1 at the inlet end 21 of the roller table 2 . The rail shape sensing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com