Rotary lifting maintenance platform

A maintenance platform, rotating lifting technology, applied to bridge parts, bridges, buildings, etc., can solve the problems of safety performance limitation, increase bridge cost, small detection range, etc., achieve safe and reliable performance, save cost, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

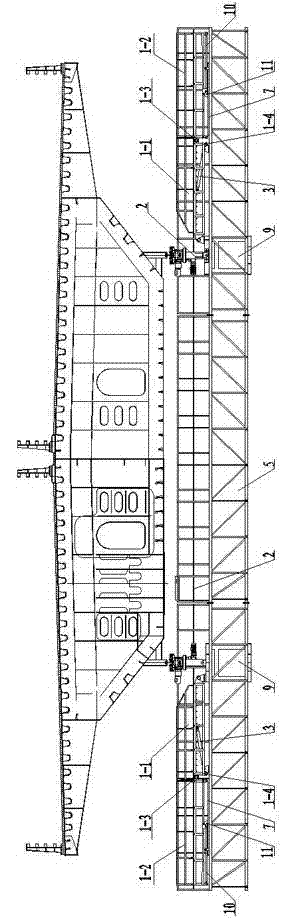

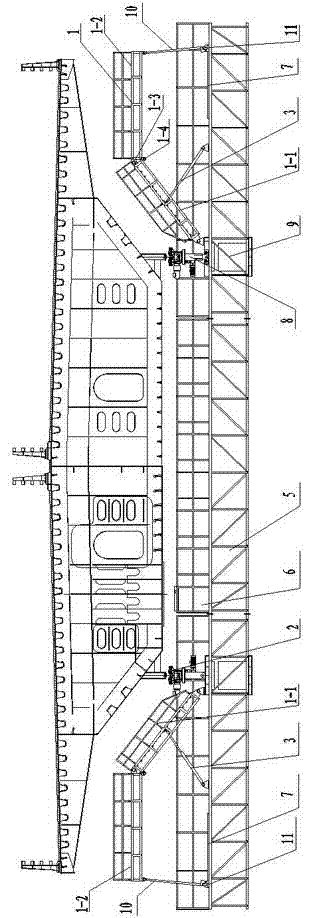

[0034] In the rotary lifting maintenance platform of the present invention, gantry frames 9 are respectively arranged at both ends of the truss system, a drive mechanism is arranged on the gantry frames 9, and a maintenance platform 1 is hinged on the gantry frames 9 (according to actual needs, the The maintenance platform 1 is hinged to both ends of the truss system), the maintenance platform 1 can swing relative to the hinge point, and a swing driving device 3 is connected between the maintenance platform 1 and the truss system, and the two ends of the swing driving device 3 are respectively hinged on On the inspection platform 1 and the truss system, the inspection platform 1 is controlled to swing relative to the hinge point. Wherein the swing driving device 3 can adopt such as figure 1 For the hydraulic expansion device shown in , when the hydraulic expansion device expands and contracts, the maintenance platform 1 can swing relative to the hinge point, so when it is nece...

Embodiment 2

[0036] Embodiment 2 On the basis of Embodiment 1, the rotary lifting maintenance platform of the present invention, wherein the truss system includes a main truss 5 and a truss beam, the main truss 5 is fixed on the truss beam, and the faucet frames 9 at both ends of the truss system Integral inspection platforms 1 are respectively hinged on the top, that is, the two integral inspection platforms 1 are respectively hinged on the faucet frame 9 at the two ends of the main truss 5 (it can also be hinged on the main truss 5), and the two swing driving devices 3 are respectively connected On the truss beam, it is possible to control the height of the integral maintenance platform by controlling the two swing driving devices 3. The hinged point of the integral maintenance platform and the main truss 5 is used as the swing fulcrum to adjust and control the height of the integral maintenance platform arbitrarily. It is composed of two I-beams and transverse connecting rods. Two swingi...

Embodiment 3

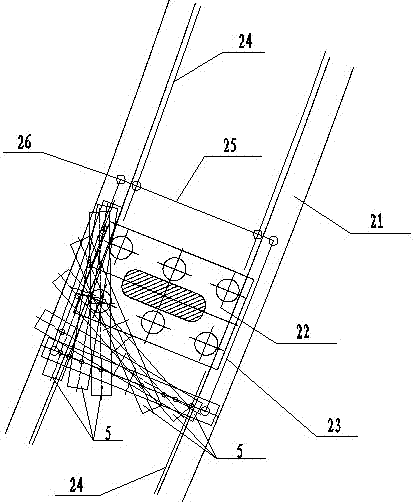

[0046] Embodiment 3 is similar to Embodiment 1 and Embodiment 2. On the basis of Embodiment 1 and Embodiment 2, the maintenance platform 1 adopts a separate maintenance platform, which includes an upper maintenance platform 1-1 and a lower maintenance platform 1-2, The upper end of the lower maintenance platform 1-2 is hinged to the upper maintenance platform 1-1, the lower end of the lower maintenance platform 1-2 is hinged to the gantry 9, and the two ends of the swing driving device 3 are respectively connected to the truss system and the lower maintenance platform 1-2, wherein the upper maintenance platform 1-1 and the lower maintenance platform 1-2 are movably connected by a rotating pin shaft 1-3. Positioning holes are respectively arranged on the upper maintenance platform 1-1 and the lower maintenance platform 1-2. When the two positioning holes are aligned, the positioning pin shaft 1-4 is inserted in the positioning hole. At this time, the positioning pin shaft 1-4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com