System for adjusting load characteristics of conical spring

A helical spring and load characteristic technology, which is applied in the field of conical coil spring load characteristic adjustment system, can solve the problems of wire diameter deviation, load characteristic deviation, no load characteristic, etc., and achieve the effect of reducing operation time and trial times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

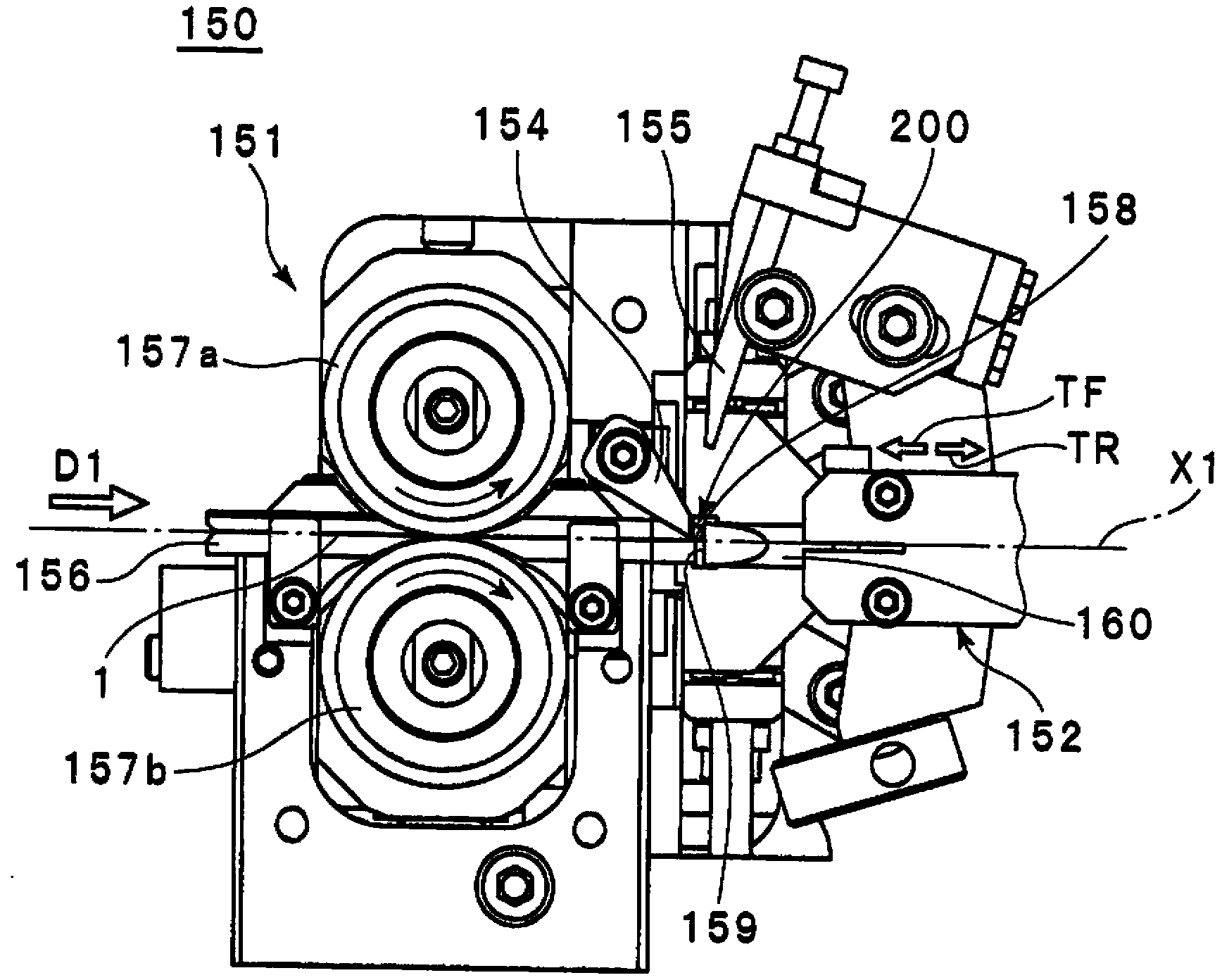

[0046] according to Figure 1 to Figure 5 A first embodiment of the present application related to a coil spring forming device (coil spring machine) will be described.

[0047] The coil spring machine (wire spring forming device) 150 of the first embodiment has: a wire rod sending unit 151, which sends the wire rod 1 to the forming table 200; Mandrel 153 guides the bent wire 1; pitch tool 154 pushes the bent wire 1 to the coil forming direction to form a helical coil; and cutting unit 155 at the end of the coil Wait until the wire 1 is cut off.

[0048] The wire feeding unit 151 has: a wire guide 156 having a guide groove 156a for guiding the wire 1 along the axis X1 of the wire 1; Drive to grip and rotate the wire 1 on the wire guide 156, and convey it to the front end side (D1 direction of the figure) of the wire guide 156; and send out the wire rod to the forming table 200.

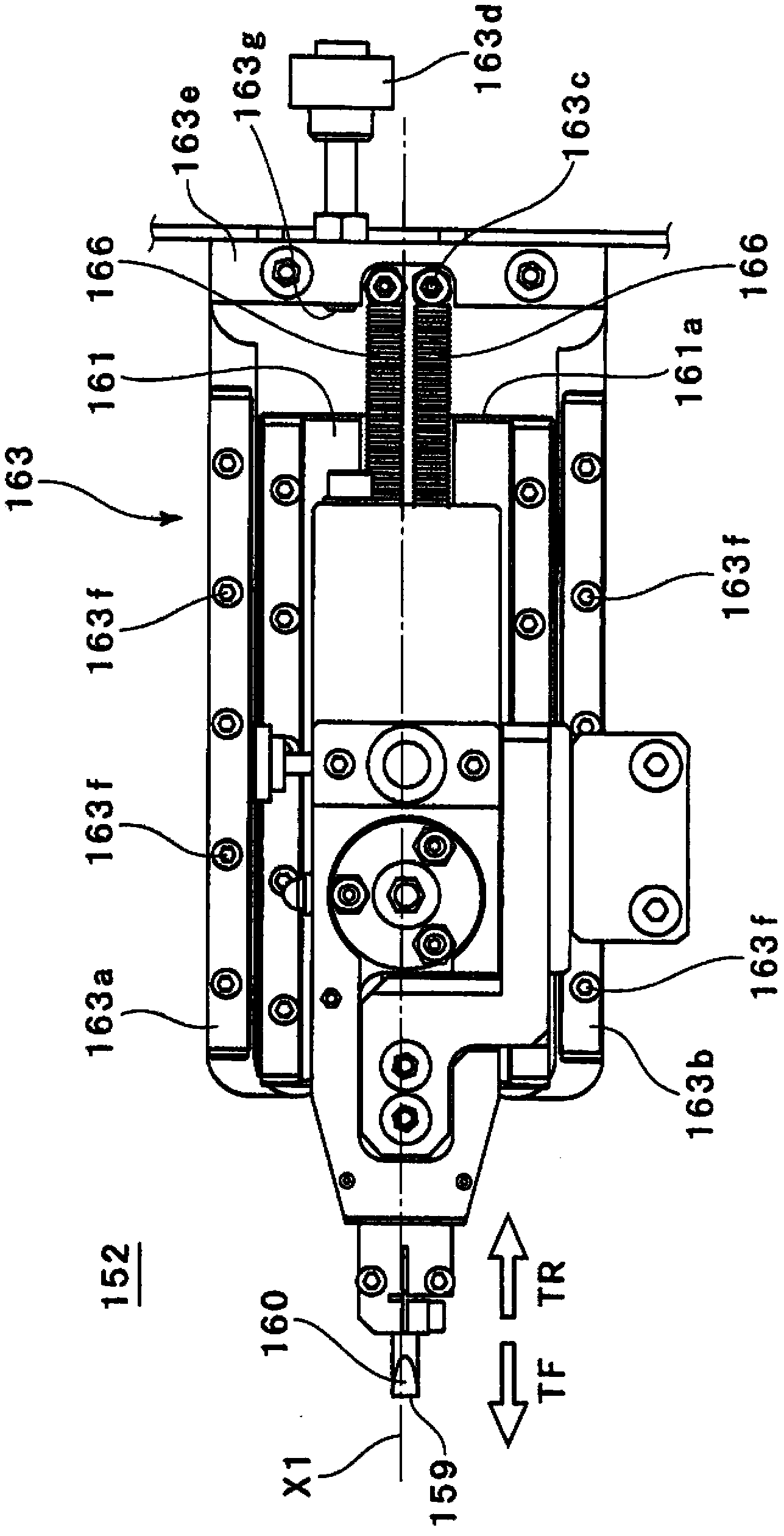

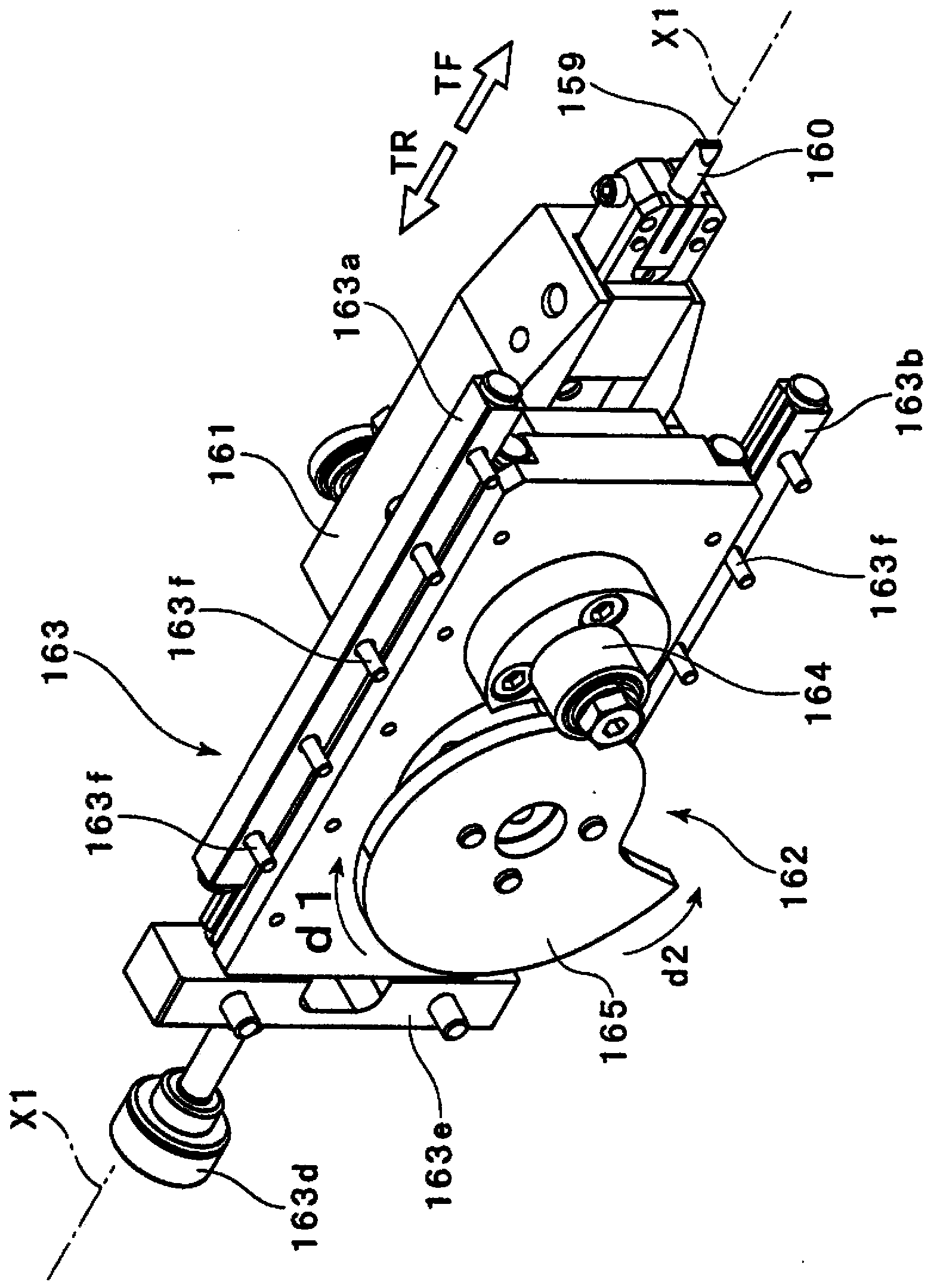

[0049] The tip tool unit 152 is composed of the following mechanisms: a tip tool 160, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com